Back from traveling for a while and had some time to work on getting ready to stain and finish this rifle. There was a recent thread on applying iron nitrate solution more than once, how long to let an application dry before heat blushing, etc, etc. And of course, anyone who has ever used a stain on wood knows that the wood gets a vote as well. Different pieces of even the same species of wood will take stain differently. In addition, different ways of preparing iron nitrate solutions will give different results. The following is not an exhaustive study by any means, but it sufficient for me to decide how I want to stain this particular rifle. I post it here as it may be useful to others.

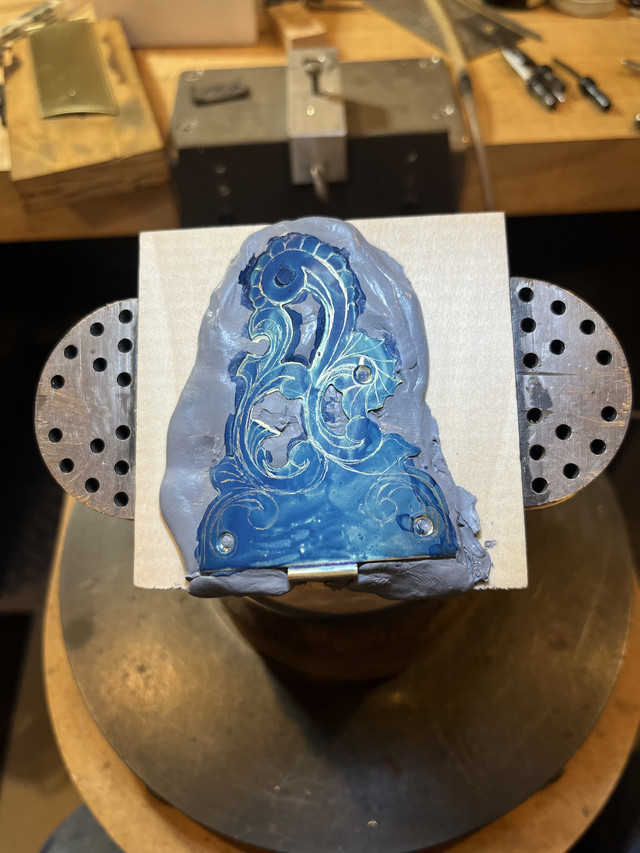

To start, the strip of wood I am using came off thew left side of the stock along the barrel. The surface was sanded to 320 and then four different solutions of iron nitrate were used to stain short sections of the wood. The fifth solution was 70% nitric acid only cut 50 / 50 with water just to see what effect nitric acid alone would have on coloring the wood. The following picture shows all five solutions and the result of a single application of each solution which was then allowed to dry. Subsequent heat blushing left each solution as you see it. No finish was applied but the surface was wetted with mineral spirits before the picture was taken. PS....click on the pictures and make them larger.....easier to see the resulting stain color.

Let me describe how each iron nitrate solution was prepared. Starting from the left:

1) The first solution is the plain 35% nitric acid alone containing no iron at all. As a note, I should have also tried the full strength 70% acid as well....but I didn't.

2) The second bottle contains an iron nitrate solution I prepared in 2009 in accordance with information Bill Knight had published. In short, it involved dissolving nails in concentrated nitric acid in an ice bath (to keep the solution temperature from getting too high) and adding nails until the acid was exhausted. The bottle was kept loosely caped for several weeks as the reaction continues for some time and can build pressure in the bottle.

3) The third bottle contains an iron nitrate solution made by adding 14 grams of ferric nitrate crystals to 150 milliliters of denatured ethanol. The ferric nitrate goes immediately into solution but after a few days an orange precipitate forms. When applying the solution, I shook the bottle and applied the precipitate with the solution.

4) The fourth solution was prepared, again with ferric nitrate crystals, this time added to distilled water until the solution was saturated (i.e.no more ferric nitrate would disolve at room temperature).

5) The last bottle contains a much weaker solution of ferric nitrate made with 1 teaspoon of ferric nitrate in 200 milliliters of water.

The top photo here shows the wood strip and all the bottles of various solutions. The next two pictures show closer pictures so that you can see the effect of each stain a little better. All thee photos were taken in afternoon sunlight.

Personally, the two most concentrated solution produced a color I liked the best (#2 and #4). Not surprising that they would produce the darkest color in one pass. However, the Bill Knight version (#3) came out a little more brown while #2 and #4 were a little more red. The weak solution (#5) is very brown and did not produce a very pleasing color or accentuation of the grain (in my opinion).

Just thought others might like to see the results of this quick test. One final note, actual finish would make the stain results show even better. Wetting with mineral spirits was just a quick expedient.