I used the coning tool from Joe Wood ([email protected]) on a Bobcat barrel that I put a wood stock on just to see how it would work , followed Joes instructions alot easier to load shot a tighter group. It was very hard to load before even with .010 patch . Also I read some where that some one studied muzzel loader displays in several museums and that not one contained a short starter. I guess they didn't have time to use one if there was some mad warriors coming at you.Just my 2cents worth but what do I know

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Article in Muzzleloader Magazine

- Thread starter roundball

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 89

Coned barrels go way back, as there is no evidence of short starters being used before at least the 1840, with the advent of false muzzles. Research done on possible bags before that time show no evidence of short starters, and no evidence of any loop inside the bag to hold the short starter. There are still bags in collections and museums that date back to the French and Indian War, and some from earlier times, so there is ample information to research.

I think trapper is right about following Joe Wood's instructions, and polishing the rifling where the coning tool has cut into it. If you don't do this well, or correctly, the burrs on the edges of the rifling will cut patches, coming and going. After a couple of hundred shots, however, these burrs will be worked off, and the problem will end. Using steel wool, or any of the fine grit abrasive cloths will speed the return to uncut patches.

As to accuracy, If the muzzle is square to the bore, and the coning is centered, there should be no trouble with the release of the ball. It does help if you leave a little bit of rifling at the muzzle, but its not really necessary. By the time the ball reaches the muzzle, its traveling at muzzle velocity and passes the muzzle too quickly for the gases to upset the ball, PROVIDED the muzzle is square to the bore. Its one of the last thing checked by shooters, and it should be in the top five instead.

I think trapper is right about following Joe Wood's instructions, and polishing the rifling where the coning tool has cut into it. If you don't do this well, or correctly, the burrs on the edges of the rifling will cut patches, coming and going. After a couple of hundred shots, however, these burrs will be worked off, and the problem will end. Using steel wool, or any of the fine grit abrasive cloths will speed the return to uncut patches.

As to accuracy, If the muzzle is square to the bore, and the coning is centered, there should be no trouble with the release of the ball. It does help if you leave a little bit of rifling at the muzzle, but its not really necessary. By the time the ball reaches the muzzle, its traveling at muzzle velocity and passes the muzzle too quickly for the gases to upset the ball, PROVIDED the muzzle is square to the bore. Its one of the last thing checked by shooters, and it should be in the top five instead.

"first of all, bad word-second of all, i hope that isn't true because we can't fight amongst ourselves'

it has nothing to do with fighting amongst ourseves, there is just a grassroots type movement to standardize the type of equipment used in ML hunting seasons an it is not about a particular type of ignition a gun uses but the degree of modern technology which can put the modern ML's on parr with many centerfires which defeats the need for having a seperate seasson for them,the mostly loosely defined ML hunting regs have over the years not considered the possibility that one would tweak a typical ML to make it more like a centerfire in handling and ballistic performance, the idea is to try and get a realistic balance back in place in the type of gear that is used in ML seasons, else the next step could be a self contained cartridge with projectile powder and primer that could be extracted from the breech but only loaded from the muzzle, this might well appear to be a gimmick to use a kind of weapon in a season desogned for a different type of weapon? and it would be and some feel we have allready come to thet point in some areas with some of the modern technology allowed in ML hunts, there will allways be seasons for general weapon use which is where many feel some of the modern stuff would better be suited.

it has nothing to do with fighting amongst ourseves, there is just a grassroots type movement to standardize the type of equipment used in ML hunting seasons an it is not about a particular type of ignition a gun uses but the degree of modern technology which can put the modern ML's on parr with many centerfires which defeats the need for having a seperate seasson for them,the mostly loosely defined ML hunting regs have over the years not considered the possibility that one would tweak a typical ML to make it more like a centerfire in handling and ballistic performance, the idea is to try and get a realistic balance back in place in the type of gear that is used in ML seasons, else the next step could be a self contained cartridge with projectile powder and primer that could be extracted from the breech but only loaded from the muzzle, this might well appear to be a gimmick to use a kind of weapon in a season desogned for a different type of weapon? and it would be and some feel we have allready come to thet point in some areas with some of the modern technology allowed in ML hunts, there will allways be seasons for general weapon use which is where many feel some of the modern stuff would better be suited.

I believe there is plenty of evidence that some original American made guns were coned. Peter Alexander refers to coning being a common practice on swamped barrels. I know several owners of original guns that seem to have been coned at some point in thier life. :hmm:

Also. Graywolf was kind enough to post this a while back on another board. I don't think he will mind me reposting.

FWIW -

Bill Large - per J. Baird (Hawken Rifles)

"I find Hawken barrels mostly made out of what old timers called plain, dead iron, bend slightly and it is bent, no spring. Some were copper-steel, and it was dead iron too. Some of black iron, this is harder. I find none like the Great Western Gun Works generally made, copper-steel and full of flaws and crawfish holes. The average twist is 7 grooves, one turn in 48", some of the latest 6 grooves, a turn in 48" and I don't think they were of before 1850 vintage. Grooves run 12 to 14 thousandths deep and mostly about equal, and in some cases lands wider than the furrows. All were belled and showed signs of the funneling tool commonly used by most gun smiths, as a request of the owner, to permit easy and fast reloading. They were all choked, mostly a gradual choke, this is done with the common cutting operation, in the hands of a skilled craftsman, knowing how to use one; sort of sixth sense, by feeling and doing what you want as you work."

J. Baird describing the H & C "Parkman" Rifle's Barrel

Lands are cut with a radius on top, seven lands and grooves, with one turn in 48 inches..........

Of .50 caliber, the bore is a slight taper from the breech to a point about 9 112 inches from the muzzle. Here a choke is apparent for about 8 inches, then from there to the muzzle, a slight flaring is seen. Measuring approximately .0005, about 1/4 inch from the end of the barrel, this flare suddenly increases an additional .002, giving the impression of slight funneling from rod wear. Close inspection has revealed that this is not the case, and that this is a deliberate relieving of the muzzle...

Chuck - Wild Rose Trading Co

Also. Graywolf was kind enough to post this a while back on another board. I don't think he will mind me reposting.

FWIW -

Bill Large - per J. Baird (Hawken Rifles)

"I find Hawken barrels mostly made out of what old timers called plain, dead iron, bend slightly and it is bent, no spring. Some were copper-steel, and it was dead iron too. Some of black iron, this is harder. I find none like the Great Western Gun Works generally made, copper-steel and full of flaws and crawfish holes. The average twist is 7 grooves, one turn in 48", some of the latest 6 grooves, a turn in 48" and I don't think they were of before 1850 vintage. Grooves run 12 to 14 thousandths deep and mostly about equal, and in some cases lands wider than the furrows. All were belled and showed signs of the funneling tool commonly used by most gun smiths, as a request of the owner, to permit easy and fast reloading. They were all choked, mostly a gradual choke, this is done with the common cutting operation, in the hands of a skilled craftsman, knowing how to use one; sort of sixth sense, by feeling and doing what you want as you work."

J. Baird describing the H & C "Parkman" Rifle's Barrel

Lands are cut with a radius on top, seven lands and grooves, with one turn in 48 inches..........

Of .50 caliber, the bore is a slight taper from the breech to a point about 9 112 inches from the muzzle. Here a choke is apparent for about 8 inches, then from there to the muzzle, a slight flaring is seen. Measuring approximately .0005, about 1/4 inch from the end of the barrel, this flare suddenly increases an additional .002, giving the impression of slight funneling from rod wear. Close inspection has revealed that this is not the case, and that this is a deliberate relieving of the muzzle...

Chuck - Wild Rose Trading Co

Happy ypu put that up out of the "BOOK of HAWKEN" or I was going to, :rotf: and my eyes got worn out reading all of this and the Muzz story 3 times too,(mine came today) see a lot of if,and but, lets try... some grps shot better some worse sounds like a normal day to me, in truth I have 2 and they are not near as deep as the one in story, I dont know that it made them shoot any better but am sure yhey didnt shoot worse. :hmm: Fred :hatsoff: part 2 of story may help, but I'd take Bill Large's word to the bank!

Quite a few original rifles were coned, generally a rather short, sharp taper, more like an extra deep crown. Many folks take it for ramrod wear but it is concentric to the bore, ramrod wear tends to be much more pronounced on one side than the other. I appears as if they used a common taper reamer. Personally, I think the advantages of a coned muzzle are highly over rated, if you load a very tight patch and ball combo you'll still need a short starter and if you load very loose combos you don't need a starter even with a conventional crown. I think "polishing" the crown will ease ball starting and can do no harm. With most mass produced barrels the crown is pretty rough, often a burr of metal is turned into the bore, both lands and grooves. Carefully working with a needle file to remove the burr will improve both loading and accuracy.

I might add that the Muzzleloader test was done in a lathe, using a piloted half reamer, not at all like Joe Woods hand tool. My pard, GreenMountainBoy, has coned several barrels with a Joe Woods tool and gets match grade accuracy but he also uses very thick canvas patching which will never blow out nor burn through. His results may not translate to the .005" to .015" patching most folks on this forum tend to favor.

I might add that the Muzzleloader test was done in a lathe, using a piloted half reamer, not at all like Joe Woods hand tool. My pard, GreenMountainBoy, has coned several barrels with a Joe Woods tool and gets match grade accuracy but he also uses very thick canvas patching which will never blow out nor burn through. His results may not translate to the .005" to .015" patching most folks on this forum tend to favor.

Huntin Dawg said:I think the tool used has a lot to do with it. They coned at 2.8 degrees which left no rifling at the muzzle. They also polished it a little. They essentially created a funnel at the muzzle.

I just ordered a coning tool from Joe Wood. The taper of his tool is MUCH more gradual. He said around 1 degree as measured by one of his customers....

HD

For the record, the tool that was used to cone the test barrel had a 2.8 degree included angle.

That makes the angle per side a 1.4 degree angle.

For the folks who were more interested in Debbie's pony tail than in the trigonometry lecture: If the rifling groves were .010 deep at the muzzle before it was coned, a tool with a 1.4 degree (per side) angle would have to cut .010/tan 1.4 degrees or .409 inches deep into the bore to remove the grooves.

Looking at the picture on page 51 of the MUZZLELOADER magazine it looks like the tool cut to about this depth before polishing which would indicate that the diameter at the muzzle was not appreciably oversize.

For those folks who haven't subscribed to MUZZLELOADER, the barrel's bore was indicated in to zero with the barrel mounted in a 4 jaw chuck on a lathe.

The coning tool had a brass bore pilot to guide ride in the bore and the rear of the tool was centered and guided by using the lathes tailstock. A more precise alignment could not be asked for.

zonie

Greenmtnboy

62 Cal.

- Joined

- Dec 10, 2005

- Messages

- 2,582

- Reaction score

- 12

CoyoteJoe said:I might add that the Muzzleloader test was done in a lathe, using a piloted half reamer, not at all like Joe Woods hand tool. My pard, GreenMountainBoy, has coned several barrels with a Joe Woods tool and gets match grade accuracy but he also uses very thick canvas patching which will never blow out nor burn through. His results may not translate to the .005" to .015" patching most folks on this forum tend to favor.

Howdy folks just got out of the woods fer a few days to go to shoot with YotieJoe and thought I would throw my two cents in on this topic.

I used Joe Woods coning tools with great success!!

He is a very nice man to talk to and he sent me my tools before I could get a check in the mail.

That kinda trust is going by the way side in this day an age.

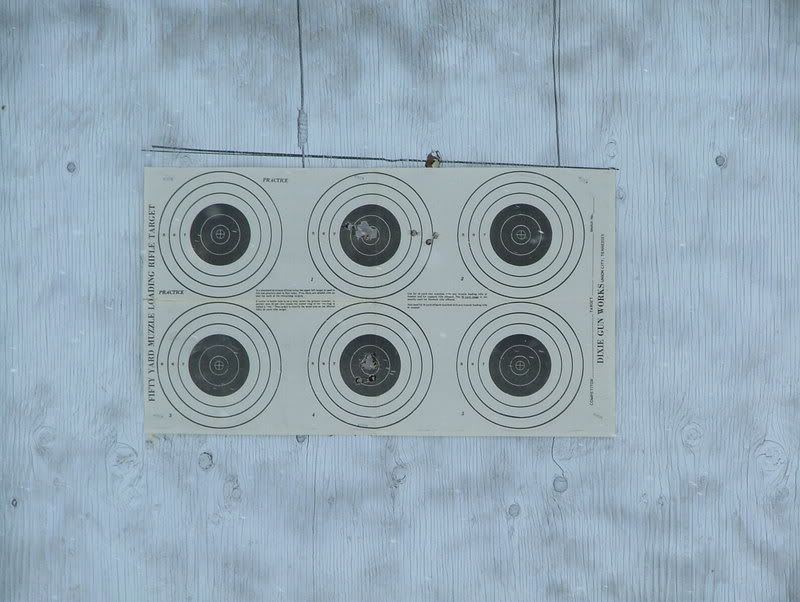

I coned a 36 cal greenmtnbarrel Joe cut down for me to fit a Blueridge from Cabala's. I am posting the first groups on paper at 50 yrds, Yes that white stuff blowing side ways is snow and yes it is windy. All that aside after my first three shots and ajusting my sights fer windage I was pritty happy with the next groups. Two groups five shots at 50 yrds lots of wind and snow but I made do.

I have hunted with this rifle for three years now and have head shot numerous grouse, bunnies, and marmots with it, I have never noticed torn patches and have always gotten consistant accuracy.

That said I prabably won't do it on any other rifles because when I cut my patch at the barrel, if I am not careful it is easy to pull your ball and patch out of the barrel wile cutting. And I do use a ball starter so typical factory crown is fine. And I have never had a problem loading a second shot wile hunting.

I also coned a TVM 45 pistol so I could load it on the fly, I get one inch groups with it at 25 yrds. no blown patches

I would post those pistol pic but I haven't put them on my lap top as of yet.

Also some barrel companies will not take a barrel back if it has been coned even if the defect is the barrel makers falt.

Similar threads

- Replies

- 3

- Views

- 341

- Replies

- 3

- Views

- 2K

- Replies

- 145

- Views

- 10K