fischereco2

36 Cal.

- Joined

- Aug 7, 2014

- Messages

- 95

- Reaction score

- 1

Hey all,

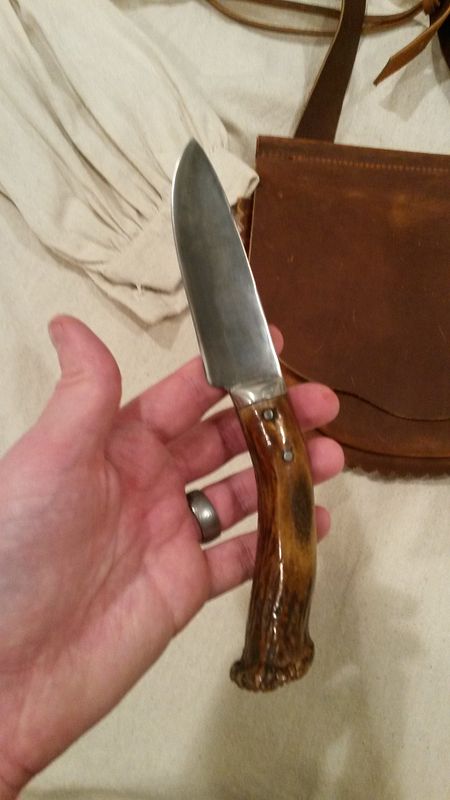

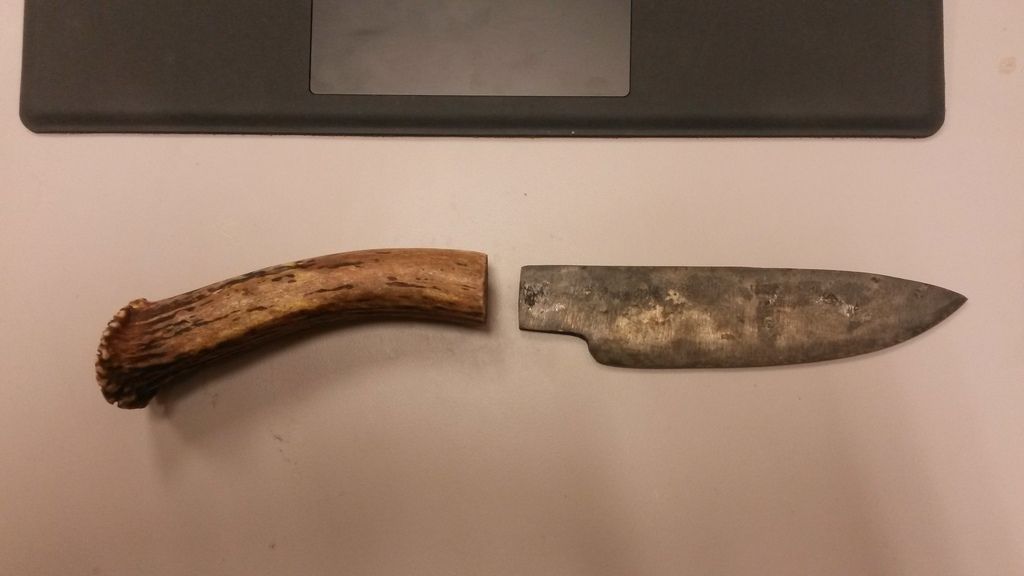

After remodeling my forge yesterday I decided to make a quick blade. I've been needing a good little knife for my shooting bag so I found a piece of antler and made a small little 4.5" blade to match. I'm a little worried my tang is too short though. Do you think with a small blade like this a quarter tang with a rivet will be enough to make it stable?

I could draw out the tang more but I have already heat treated the blade so I'm hoping it will be sufficient. I feel like I've seen some original knives with very short tangs like this but of course I can't find any of them now.

After remodeling my forge yesterday I decided to make a quick blade. I've been needing a good little knife for my shooting bag so I found a piece of antler and made a small little 4.5" blade to match. I'm a little worried my tang is too short though. Do you think with a small blade like this a quarter tang with a rivet will be enough to make it stable?

I could draw out the tang more but I have already heat treated the blade so I'm hoping it will be sufficient. I feel like I've seen some original knives with very short tangs like this but of course I can't find any of them now.