History indicates that it can be done. Damascus barrels from the early 1800's were apparently reamed and honed using these tools. If you can properly anneal the high carbon steel and avoid course pearlite it will be easier. But, one reason that tools needed to be replaced so often was probably due to course pearlite in the high carbon steel causing some damage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel boring bench

- Thread starter Matt Maier

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

plmeek

40 Cal.

Matt, if you make your boring bits and reamer out of modern tool steel, either water or oil hardening, I'm sure they would cut the modern steels used to make the barrels.

Building the boring bench and making the traditional tools would take a bit of time and effort, but I don't think that would compare to the time and effort it will take you to make the two shotgun barrels for the double.

Most people that make forge welded muzzleloader barrels today use wrought iron skelps. Obviously, modern steels like 1018 and hardening steels like 1082 can be forged welded because knife makers do it all the time. To me, the challenge would be making a full length shotgun barrel.

Here is an interesting video of a guy forging a damascus twist pistol barrel from the modern steels mentioned above. His barrel is only a few inches long, but notice all the work he puts into it, and he's using modern power hammers.

He has several videos on Youtube of different pistol barrels he's made.

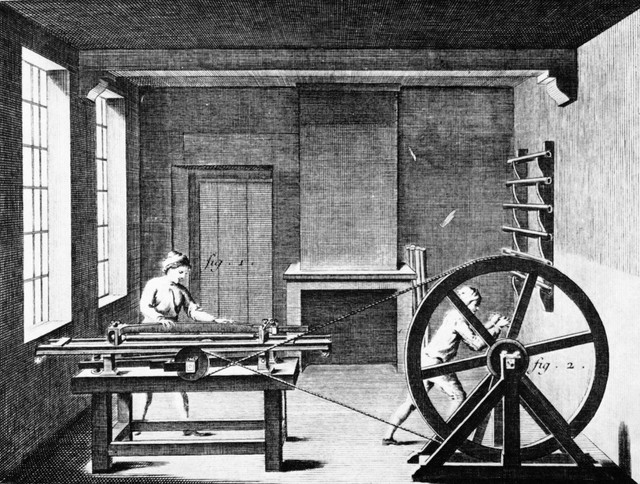

I'm not sure just how traditional you're trying to be in this build, but how are you planning on shaping the exterior dimensions of the barrel? The 18th and early-19th century method was with very large grinding wheels. I think this image is from 1850s Birmingham, England. This is how the English got such thin barrels towards the muzzle.

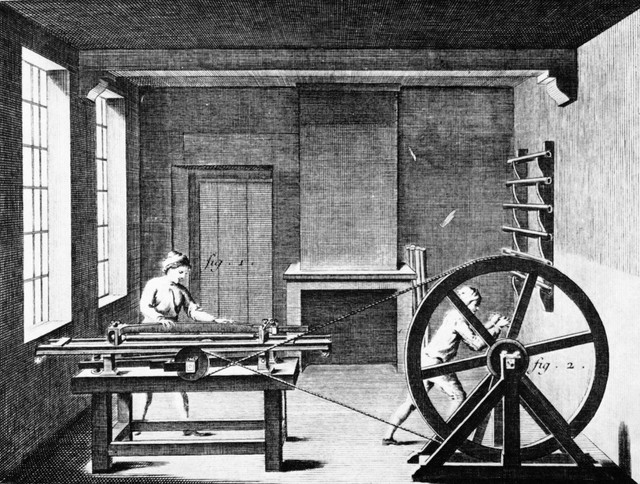

The image below is from 17th century France and shows a different method where the grinding wheel was smaller and located below the barrel on a bench similar to the boring bench. The barrel could be moved lengthwise over the grinding wheel and possibly rotated like on a lathe. They could grind octagon flats as well as the round section of an octagon-to-round barrel with the same setup.

Building the boring bench and making the traditional tools would take a bit of time and effort, but I don't think that would compare to the time and effort it will take you to make the two shotgun barrels for the double.

Most people that make forge welded muzzleloader barrels today use wrought iron skelps. Obviously, modern steels like 1018 and hardening steels like 1082 can be forged welded because knife makers do it all the time. To me, the challenge would be making a full length shotgun barrel.

Here is an interesting video of a guy forging a damascus twist pistol barrel from the modern steels mentioned above. His barrel is only a few inches long, but notice all the work he puts into it, and he's using modern power hammers.

He has several videos on Youtube of different pistol barrels he's made.

I'm not sure just how traditional you're trying to be in this build, but how are you planning on shaping the exterior dimensions of the barrel? The 18th and early-19th century method was with very large grinding wheels. I think this image is from 1850s Birmingham, England. This is how the English got such thin barrels towards the muzzle.

The image below is from 17th century France and shows a different method where the grinding wheel was smaller and located below the barrel on a bench similar to the boring bench. The barrel could be moved lengthwise over the grinding wheel and possibly rotated like on a lathe. They could grind octagon flats as well as the round section of an octagon-to-round barrel with the same setup.

Matt Maier

36 Cal.

- Joined

- Sep 3, 2013

- Messages

- 112

- Reaction score

- 15

Hi Phil, since I am trying to replicate a shotgun from the early percussion era (think Forsyth's so-called scent bottle lock), the barrels are going to be tapered round. I do not intend to make octagonal flats. I have seen Steve Culver's video several times and it never ceases to be fascinating.

As far as how "traditional" I am going to go. I do want to forge the barrels myself, I am willing to do that work as I think it would be an enjoyable experiment. I also want to ream it out using the bench as described in this thread. As far as shaping the external profile of the barrels, I intend to use a modern lathe turning between centers. I see no reason not to use a tool I have ready access to.

As far as how "traditional" I am going to go. I do want to forge the barrels myself, I am willing to do that work as I think it would be an enjoyable experiment. I also want to ream it out using the bench as described in this thread. As far as shaping the external profile of the barrels, I intend to use a modern lathe turning between centers. I see no reason not to use a tool I have ready access to.

jrmflintlock

45 Cal.

Good luck with your project!! Please take lots of pictures of the process and share with us!!!

Matt Maier

36 Cal.

- Joined

- Sep 3, 2013

- Messages

- 112

- Reaction score

- 15

Good luck with your project!! Please take lots of pictures of the process and share with us!!!

Sure thing. There are still some tools and materials I have yet to gather. I will be sure to keep everyone posted.

jrmflintlock

45 Cal.

It’s a dieing art. I’m glad you are taking up the torch. My goal someday is to build a Fowler from scratch! Lock, stock and barrel!!

Similar threads

- Replies

- 3

- Views

- 497

- Replies

- 29

- Views

- 2K