Wick, this is how I do it. It may not be the best way, but I have found it to be simple, fast and easy.

Say, for instance, I have a 50 caliber gun with a very rough bore. I take a 490/495 round ball and wack it a few times to swedge it out.

Then I drill a hole through (the flat part) with say a number 27, 26 drill.

Then I take an old lock bolt that is 8x32 and put it into an 8x32 die (which is in my vise) and I screw it through the die untill I shoulder it. At that point I cut off the remaining screw sticking out of the die, thus keeping the head and what is left in the die.

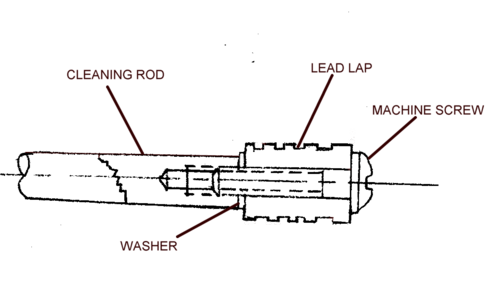

I now have a small 8x32 screw that I can screw into my cleaning rod. Before I do so, I get a couple of small washers to sandwich the flattened roundball which now I will pass the screw through and attach to my cleaning rod.

I tap (gently) the whole thing into the muzzle of the barrel and push it through to the breech, just comming to the end, but not going out. A mallet helps, with lite little taps. I add some valve grinding compound and pull it back through the barrel.

I keep doing this untill I feel it loosening up, upon which I crank a turn on the cleaning rod handle to tighten it back up and I keep pushing/pulling untill I feel I've smoothed things up a bit. I don't need to do it much, because I use aggressive valve lapping compound.

In short, I am not pouring but swedging the lead into the barrel. The idea behind the small screw is that when I turn the cleaning rod handle, the screw will draw into the rod end exerts force against the lead and squashing it outwards. The washers act as a bearing surface, otherwise the head of the screw will just tear out the hole in the lead ball.

You don't needs to use a lock bolt, but any screw from the hardware store will do.

Hope I didn't confuse you any.