-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel lapping

- Thread starter vanstg

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sabotloader

36 Cal.

- Joined

- Mar 12, 2004

- Messages

- 68

- Reaction score

- 0

vanstg, I am not a gunsmith but I have fire lapped a few barrels and it seems to work well. I just completed fire lapping a Renegade barrel last week, it was a used barrel that I had aquired and it looked terrible inside.

I had some 320 grain Reals that I had been saving for just this occasion. I lubed them up with J-B Bore Cleaner and stuffed them and a bore button down the barrel shot them with 70 grains of T7. The results were great - the barrel is really smooth now, still doesn't look like a new barrel, but it shoots sabot combinations very accurately and is now really easy to clean.

I had some 320 grain Reals that I had been saving for just this occasion. I lubed them up with J-B Bore Cleaner and stuffed them and a bore button down the barrel shot them with 70 grains of T7. The results were great - the barrel is really smooth now, still doesn't look like a new barrel, but it shoots sabot combinations very accurately and is now really easy to clean.

- Joined

- Aug 25, 2003

- Messages

- 6,502

- Reaction score

- 1,438

The latest "MUZZLELOADER" magazine has a very good article on barrel lapping. A very good method, that gives excellant results.

Fire lapping is OK if you have a dubious barrel or a barrel that isn't shooting well. If however you have an expensive custom barrel, you might be ruining it. This bit of wisdom was gleamed from the late great barrel maker, Gale McMillan.

I'm surprised that after 300 rounds you would need to lap the barrel, but all barrels are different... You could wrap 000 or 0000 aught steel wool around a ramrod or dowel and run it up and down the bore 50 to 100 times, but never remove it until the job is done on the last stroke... I use the number 50 as you already have 300 rounds through the barrel, but I doubt 100 strokes would do any harm...

Ok, question. Why not remove it until the last stroke?

This was the way I was taught and to be quite honost, I don't know for sure? I expect by removing the steel wool rod with each stroke you will continuously bunch the steel wool up creating open spaces and thin spaces of steel wool on the rod, making it harder to get it in and out of the barrel evenly... Once in the barrel the steel wool should stay constant and evenly distributed while polishing the bore...

Ok, thanks Ohio Joe. Just wondered if there was some reason for not taking it out. Take care.

- Joined

- Aug 25, 2003

- Messages

- 6,502

- Reaction score

- 1,438

BHe careful with the steel wool. You do not want to go overboard. Do not use any coarser than 0000. This is not bore lapping, all you are doing is removing tiny burrs. Acuall bore lapping is much more involved and will polish and improve acuracy if done right. Too much steel wool and you could start rounding the edges of your lands, too much and acuracy is gone, and ain't coming back.

That is correct, Wick... I left out a sentence in my earlier post that should have read, "I believe I would polish the bore before trying to lap it"... And I do believe this... In a new barrel if it has not shot in by 300 rounds I think I would polish it with the steel wool first to see if this brings it around and better accuracy is achived... As you said, bore lapping is a tough job and I would not care to tackle it unless it was the only solution left... Even then I think I would try and find someone with qualifications to lap a bore...

- Joined

- Aug 25, 2003

- Messages

- 6,502

- Reaction score

- 1,438

Fred Stutzenberger writes in "MUZZLELOADER" magazine that he uses a lathe turned oversize lead plug which is swaged into the bore for a perfect fit. No heating of the barrel is required. This method makes more sense to me since the lap fits tighter than a poured lap, which I have have had mixed results with. I have lapped only two bores, both were so bad that they could not be screwed up any worse. Both were improved, one greatly, but I have always been concerned about the relatively loose fit of the poured lap. The way I see it, if the lap is any looser than to allow movement, too much of the grit could slip into the inside corners of the lap and over cut the land edges, to the point of rounding them.Next opportunity I get to do one, I am going to try the Stutzenberger method, but with a pure lead elongated bullet. A lathe should not be necessary since it will be swaged in anyway. The problem is getting a threaded hole in the base of the bullet that is centered and squared to a cleaning or other rod. I have a friend with a Colrain barrel that has a noticeable tight spot. If he is willing I may try this on his. He is not happy with the accuracy he gets now so I figure that he has little to lose, and any improvement would be welcome.

Seems to me I remember one process where the poured lap was attached to a tapered screw, and when the rod it was attached to was struck it upset the lap enough to expand it to take up the slack. This could be done several times as the lap wore down and needed "adjustment".

If using steel wool doesn't remove enough material to smooth out the bore, then lapping with an abrasive may be the only recourse.

This actually removes material so it in a sense wears out the bore but it is sometimes the last resort.

Creating a poured lead lap is difficult and sometimes leads to more problems than it is worth.

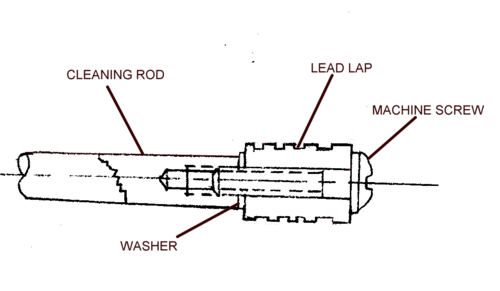

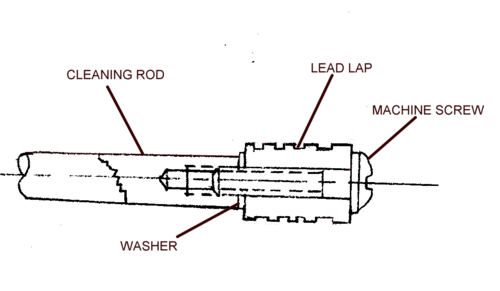

Using some existing lead slug or some purchased bullets like a Maxi Ball, Maxi Bullet can be a time saver if you drill a hole thru the center and mount it as shown in the following picture:

Notice that the screw does not bottom out in the tapped hole in the cleaning rod. If it does, shorten the screw a thread or two.

As the slug wears down, tightening the screw will expand it. Do not loosen the screw. It should be tight at all times.

The screw should always have at least 2 1/2 or more threads engaged with the cleaning rod to prevent it's pulling out.

Also, don't use an aluminum or wooden cleaning rod. They are not strong enough to prevent the screw from pulling out, or to provide the strength the screw needs to expand the plug. Buy a good steel or stainless steel cleaning rod to use with this lap.

This actually removes material so it in a sense wears out the bore but it is sometimes the last resort.

Creating a poured lead lap is difficult and sometimes leads to more problems than it is worth.

Using some existing lead slug or some purchased bullets like a Maxi Ball, Maxi Bullet can be a time saver if you drill a hole thru the center and mount it as shown in the following picture:

Notice that the screw does not bottom out in the tapped hole in the cleaning rod. If it does, shorten the screw a thread or two.

As the slug wears down, tightening the screw will expand it. Do not loosen the screw. It should be tight at all times.

The screw should always have at least 2 1/2 or more threads engaged with the cleaning rod to prevent it's pulling out.

Also, don't use an aluminum or wooden cleaning rod. They are not strong enough to prevent the screw from pulling out, or to provide the strength the screw needs to expand the plug. Buy a good steel or stainless steel cleaning rod to use with this lap.

I dont know what you would call what I did and nobody told me to do this but it worked.I had a lyman GPR bought new and could not get to group the rifle would scatter over about a foot circle at 50 yrds.I looked down the barrel and it looked really rough.Not knowing anything about lapping I took a small amount of 0000 steel wool and wrapped it around my cleaning jag and only ran it up and down the barrel mabey 20 times.I then took a cloth cleaning patch and used regular polishing compound and wetted with hot water and worked it up and down the bore until it shined.The rifle has become one of my keepers because it groups so tight.

kentucky bucky

45 Cal.

- Joined

- Jul 10, 2004

- Messages

- 586

- Reaction score

- 1

A dry, green scotchbrite pad, secured with tape and wrapped around a ramrod will take out alot of rough places and shine it up. It mainly polishes rather than removes metal. The rolled up pad must fit the bore rather tight and turn it with the rifling as you go. I can't take credit for this technique, I learned it from Don Getz on another forum!

Similar threads

- Replies

- 11

- Views

- 692