-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bronze casting

- Thread starter John92

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here's a nice Youtube video on casting:

http://www.youtube.com/watch?v=SAomnhzif7w

They are using a filter to remove impurities as well as skimming them off the top. Bronze should have a sleeve of seamless steel (this is a requirement among many blackpowder organizations), though I know of some people/manufacturers that don't use sleeves, but for a cannon, I personally would probably never fire one without it).

Having never made one, there's not much more I can tell you, but there is much more information available if you search a bit. Good luck, and have fun!

They are using a filter to remove impurities as well as skimming them off the top. Bronze should have a sleeve of seamless steel (this is a requirement among many blackpowder organizations), though I know of some people/manufacturers that don't use sleeves, but for a cannon, I personally would probably never fire one without it).

Having never made one, there's not much more I can tell you, but there is much more information available if you search a bit. Good luck, and have fun!

Last edited by a moderator:

robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 22

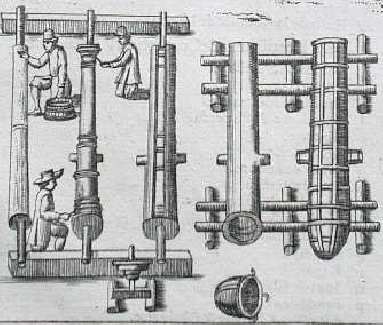

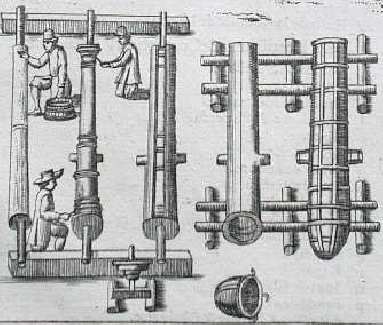

Doing it the old fashioned way, you melt cannon and bits of old bells (morceuax de vielle cloches) then pour into a clay mould buried vertically in a sand pit.

The bore mold is held in place with iron rods running the full width, you cut them flush afterwards. I think they are called chaplets, always fun to look for them on an old bronze gun.

The impurities tend to float to the top as it sets from the bottom up, so they sometimes cast overlength then sawed the end off. The discarded piece could be a completely different alloy, short on copper and somewhat brittle :thumbsup:

The bore mold is held in place with iron rods running the full width, you cut them flush afterwards. I think they are called chaplets, always fun to look for them on an old bronze gun.

The impurities tend to float to the top as it sets from the bottom up, so they sometimes cast overlength then sawed the end off. The discarded piece could be a completely different alloy, short on copper and somewhat brittle :thumbsup:

robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 22

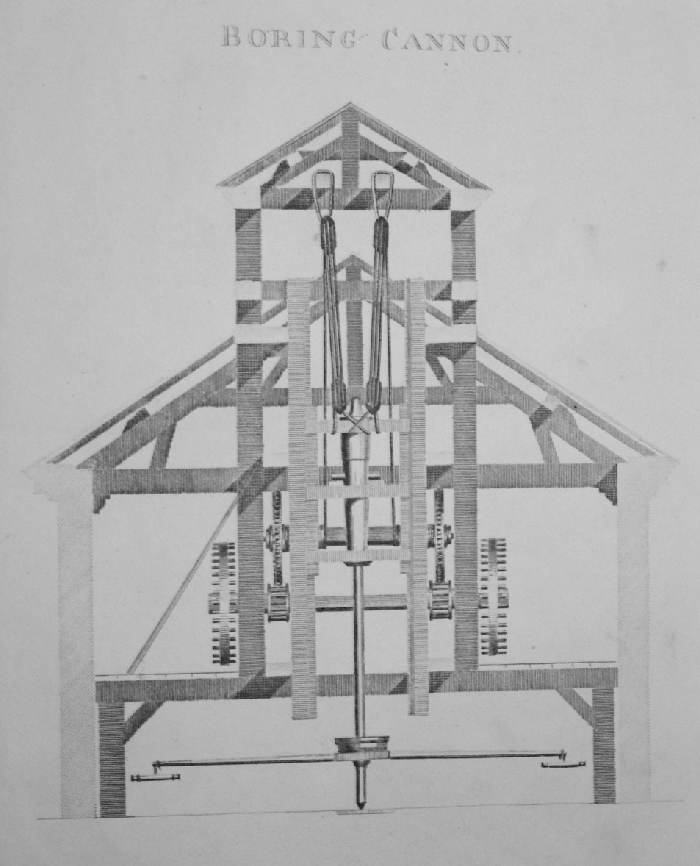

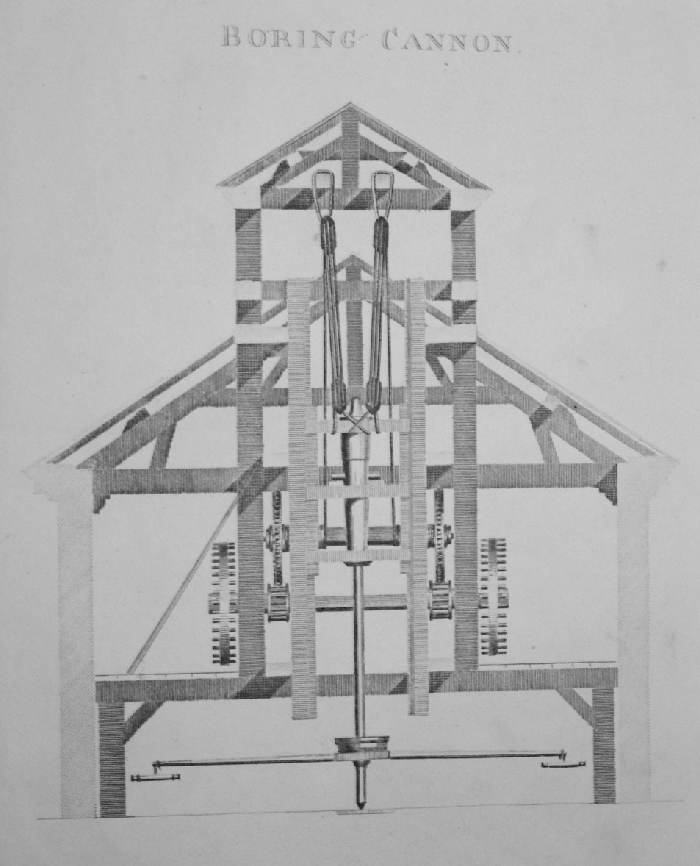

Cannon boring is iron cannon, came later. If a cast bronze bore had imperfection over .1" (not sure of that measurement) the army rejected it.

We do a fair amount of sand casting at the university where I teach, mostly aluminum, but we have played with the hotter stuff at times. Get yourself a good how to book on the subject, the Gingery series is good basic stuff and will get you started. I would recommend starting small and playing around with aluminum until you get the hang of it.

We use an oil bonded sand for most of the work we do, budget casting supply will sell you small amounts of this stuff and you can also order anything else you need from them, including the bronze alloys. I personally would be leary of casting the bore in place (I think it would be better to bore it out afterwards), but if you do want to try this it can be done, we have resin bonded sand that we sometimes use for things like this. You basically pour it in a form and bake it in the oven which makes it rock hard, following this you can position it in the mold and the molten metal will go around it. Any movement and you pretty much better start over, the stuff can be easily broken out after the part has cooled.

Definitely pay attention to safety, I am still recovering from a serious non-foundry related burn to my left hand and I can tell you from first hand experience that burns have got to be one of the worst injuries you can suffer.

We use an oil bonded sand for most of the work we do, budget casting supply will sell you small amounts of this stuff and you can also order anything else you need from them, including the bronze alloys. I personally would be leary of casting the bore in place (I think it would be better to bore it out afterwards), but if you do want to try this it can be done, we have resin bonded sand that we sometimes use for things like this. You basically pour it in a form and bake it in the oven which makes it rock hard, following this you can position it in the mold and the molten metal will go around it. Any movement and you pretty much better start over, the stuff can be easily broken out after the part has cooled.

Definitely pay attention to safety, I am still recovering from a serious non-foundry related burn to my left hand and I can tell you from first hand experience that burns have got to be one of the worst injuries you can suffer.