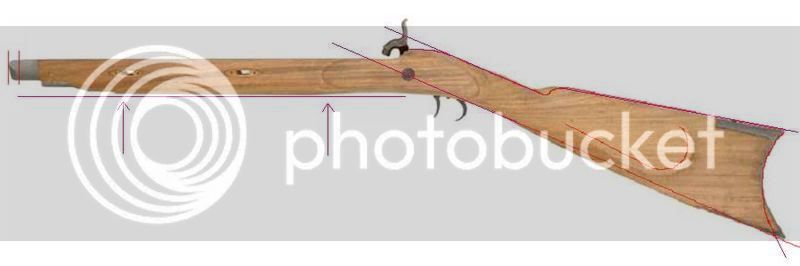

The Lyman GPR is a good starter. It does not just go together itself, so it gives you some things to think about as you build. But, it's not so difficult that you should feel any serious trepidation.

I have read some posts here which advise folks to replace the brass screws with No. 3 wood screws . . . . .

I can't for the life of me recall any brass screws on a GPR.

I think you may be refering to the small screws that retain the escutcions. The ones that come with the kits are horrible. They break off just at the heads under any stress at all and the heads are a terrible fit to just about any screwdriver you may apply to them. So, yes, toss them and replace them with a slightly larger screw of good quality. If you

must use the kit screws, enlarge the pilot holes ever so slightly before putting them in. Also, put a small bit of lubricant on the threads before starting them. They will work if you do those two things, but most first time builders don't realize it and end up breaking the heads off at least one screw. I have a kit that I "rescued" at a gun show that had been thrown together with no fitting of any of the parts whatsoever. Four of those screws were broken off.

and to consider buying a Davis replacement trigger for it.

The Davis trigger seems to be becoming a popular fix for the GPR trigger. The GPR trigger, when used as a set trigger only, is an ok trigger. The trigger pull unset using the front trigger only can be so heavy as to be near impossible to pull. The pull on that trigger will not be improved much by tuning the trigger, oiling the trigger, or just about anything else you might do to it. The problem is the geometric relationship between the front trigger hinge pin and the sear bar of the lock. The pivot point (hinge pin) of the front trigger is way to far forward of the sear bar. It's just a badly positioned lever. Your finger becomes the 50 pound kid on the teeter totter trying to lift the 90 pound kid on the other end! :shocked2: How bad varys from kit to kit. You can only move the trigger just so much since the trigger inlet is directly related to the trigger guard inlet. Fortunately, the tang bolt does not screw into the trigger plate as it does on most guns. Rather, it screws into a nut that is separatley inlet independent of the trigger plate. That means that you can move the position of the trigger back to obtain a better pull, but as said above, it could alter the position of the pre-inlet trigger guard.

1. Do they leave enough wood on the stock to allow for a good, even, close fit?

Yes, there is spare wood. You might have to work on the fit of the butt plate. Just depends on how picky you are.

2. I am aware of the difficulties of disassembling a lock that uses coil main spring. Is the lock worth taking the trouble to tune? In other words, when tuned correctly is it a good lock? Or should I just replace it from the start?

All four of the GPR kits I have worked on have had fine locks. I have not tuned any of them and have not felt a need to. There may be some improvement to be had by tuning but it just has not been necessary on any that I've seen.

3. Can the factory stampings on the barrel be draw filed off?

Sure, but you will leave a pretty good belly in the metal. Won't be pretty! :shocked2:

4. Is it feasible to draw file a taper in the barrel from nose cap to muzzle? Will it affect the under rib installation? Not a great deal of taper I just want to make it less muzzle heavy.

You could, but really, it might end up looking a bit odd with the taper starting that far forward. The under rib will be a problem. One that I built came with the rib soldered on. The more recent ones all seem to be screwed on. If the rib is screwed on, you can taper all sides of the barrel uniformly and then taper the sides of the rib a bit to match the bottom flat after tapering all the flats. I recommend against doing this for several reasons. First, if you taper it enough to significantly reduce the weight at the muzzle, it's probably going to look a bit funny. Tapered barrels can look very nice but it's the breech to muzzle taper that is aesthetically pleasing. It will also reduce the depth of the front sight dovetail. You can file a sight to fit I suppose, but it's just another thing to deal with. Lastly, the .54 GPR with it's 15/16ths barrel is not all that muzzle heavy. Most who shoot them find, like myself, that they balance rather well.

Are there any other precautions of which I should be aware?

First thing you should do is try-fit all the inlet parts and look for misplaced, out of line or over sized inletting. This has cropped up as a problem with many of the recent kits. If the inletting is way off, send the stock back to Lyman and request a new one.

Plan on replacing the front sight with a narrower blade or spend some time with a file and file it narrower. That's a personal pref of mine, but I find near universal agreement that the front sight blade is way too wide.

When you are satisfied that the parts inletting is ok, you first off want to do any fitting of the tang to breech plug hook that may be needed. If fitting is needed, it needs to be done slowly and carefully. I did over do one once and was able to fix it but metal is like wood, it's a lot harder to put it back than to remove it carefully! :haha:

Once that fit is perfect, clean up the matching faces and epoxy them together and then proceed to fit them to the wood. Be sure that the lock matches up to the nipple or touch hole. Most likely the parts will be over inlet and you will need to do some bedding where the tang recoils against the wood and under the tang itself. A bit of heat from a torch will allow you to separate your epoxy joint later.

And, finally, if you are determined to start right off replacing the trigger ($50) and the lock ($100 ++) plus messing with the barrel taper, you might want to reconsider the gpr kit in favor of a parts set from one of the major suppliers that have those features built in such as a high grade lock, tapered barrel, high grade set trigger and the inletting to go with them.

Good luck with it whatever you decide.