Brokennock

Cannon

That is turning out beautiful. Great job, both of you.

I’m always impressed by your abilities and dedication to creating works of art Dave however this time I believe you have proven that you also have a heart of gold. Josh is most certainly an individual that is capable of almost anything and I for one am absolutely amazed at his dedication , passion and abilities. I am convinced that his being coached by a master of the art is a fantastic gift.Hi,

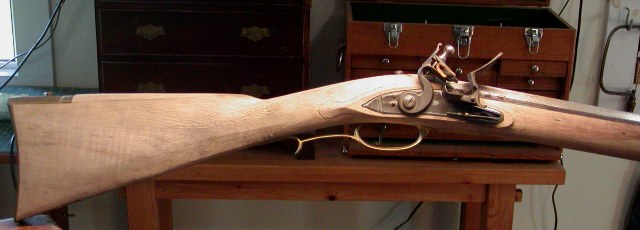

We got more done last Saturday. It was time to make and install a side plate. I modeled one from a 1770s vintage Lancaster gun and used an old cast English plate as the raw material. I cut out and filed the outline and then had Josh clean up the edges and file the bevel. He did a great job with the task.

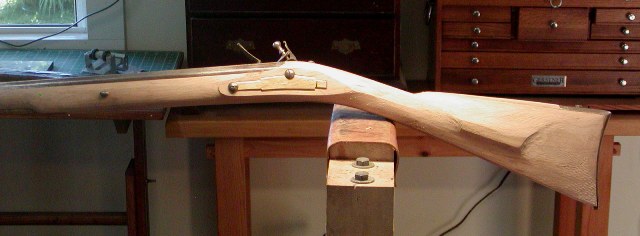

I decided to let Josh outline the mortice for the side plate because the thick brass gave him a nice edge to feel. So Josh screwed the plate in place and used a razor sharp knife with a pointed tip to trace the plate.

He did OK but he tended to put too much pressure on the knife such that it cut deep and caught wood grain that led the tip astray. He did not grasp my direction to use a light touch because all he was doing was scribing the outline. We deepened it by stabbing in after marking it. Anyway, the stock will have a few scratches around the plate after finish but they won't show very much. I corrected and cut the outline and back cut to create an edge to the mortice that Josh could feel. He removed the background.

The inlet came out great. There are a few tiny gaps but they will disappear when the wood is stained and finished. I want to emphasize how difficult this is. When using a chisel, he has to have his hand on the tool but low enough near the blade so he can use his pinky to feel where it is going. Then he has to tap the chisel with his other hand. He tends to position the chisel at the right angle but when he gets ready to tap it, he unconsciously lowers the angle of the chisel so it skips over the wood. He has to consciously raise the end of the tool before every tap. Acer had an idea that Josh may do better if, rather than a mallet, he hits the chisel with a flat weight in his hand. It may give him one less thing to think about.

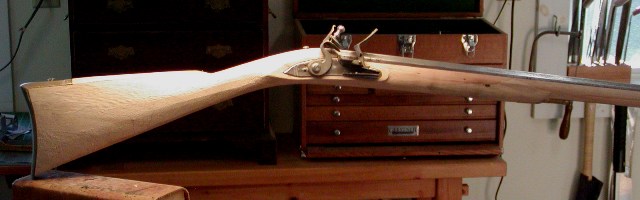

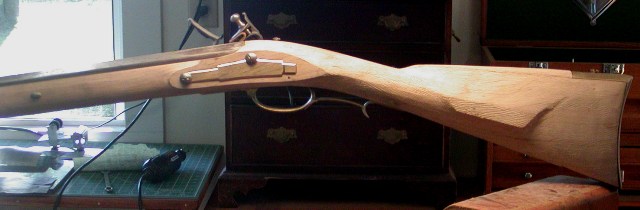

The rest of the day was shaping the stock further. Josh did well but as we get closer to the finished product it is clear that I have to do more of the work. There are subtle details that he cannot perceive but we will try to push his capabilities as far as we can. Here is where we are and you can see minor gaps in the inletting and some imprecision in shaping, but most of that will disappear in the final form and Josh has done a remarkable job.

I communicate all your responses to Josh and he appreciates the support a great deal. Thank you all for looking and commenting.

dave

Hi Sam,Simply amazing. People like you are a credit to muzzleloading and the community

Excellent!!Hi,

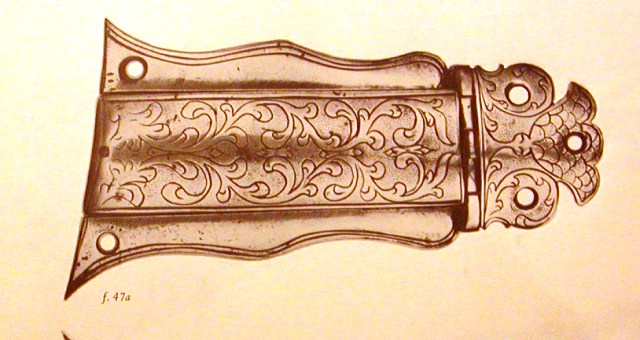

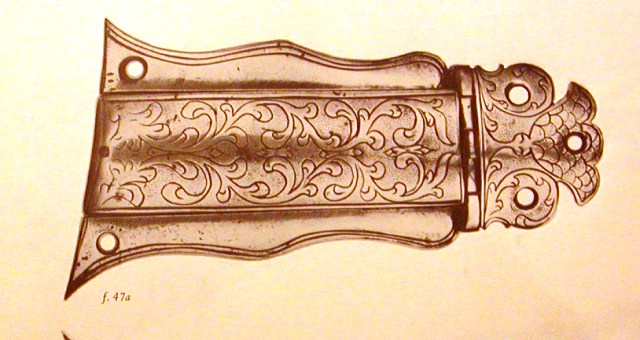

It has been a while since I posted on Josh's rifle. It is almost done. At the finishing stages I have to do most of the work but Josh helped polish the lock and brass and clean up the stock getting ready for stain. I'll be posting the finished rifle soon but I wanted to share the patch box engraving. The rifle is partly a tribute to one of Josh's teachers who helped him a lot growing up. She died recently but her family is still connected to the project. I'll engrave her first name on the side plate. She loved tulips so when I found the patch box below attributed to a gun by Jacob Dickert, we had a very appropriate original design to work with. I do not believe Dickert engraved the box. Both Rich Pierce and I think it may have been engraved by George Frederick Fainot. It still may be from a Dickert rifle but perhaps he had Fainot engrave the box. he original design is rustic and charming.

However, I wanted to make the tulip look a little more like a real tulip and clean up the lid so it was not so busy but not lose the folk art charm of the original. Here is what I came up with:

More to come.

dave

Enter your email address to join: