- Joined

- Jul 15, 2007

- Messages

- 1,994

- Reaction score

- 637

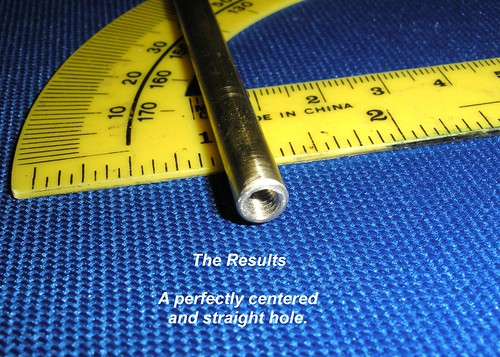

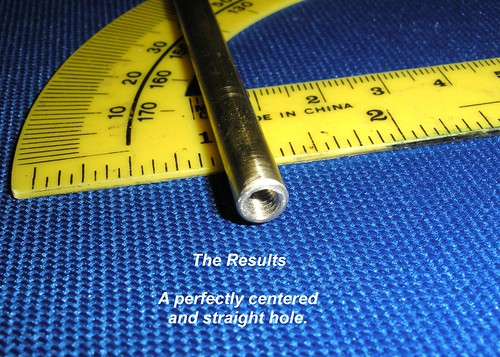

Do you need a perfectly centered and straight hole in the end of a solid rod?

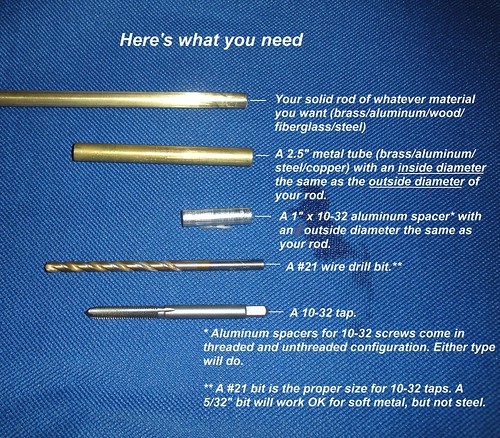

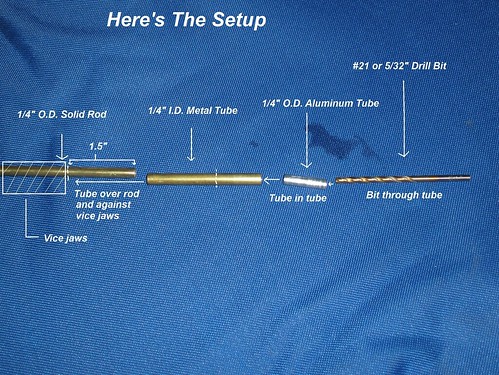

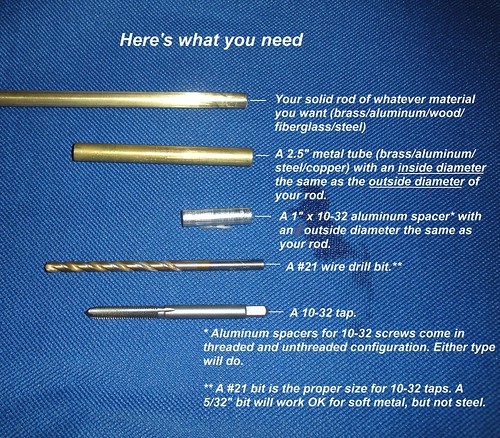

I did. I wanted a 10-32 threaded hole for mounting a cleaning jag on a quarter-inch brass ramrod. I don't have a lathe, so here's how I did it with a simple cordless drill.

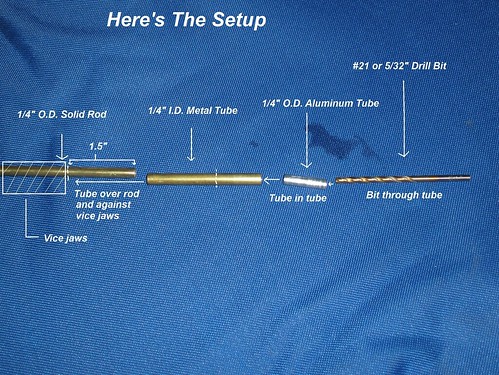

THIS EXAMPLE IS FOR A 1/4" ROD. The system will work for any diameter rod so long as you correctly match the inside and outside diameters of the components used.

Process Notes:

1. Prior to drilling the rod, you must put the aluminum spacer in a vice and run the drill bit through it so as to size the inside diameter of the spacer to be the same as the drill bit. (Other size spacers, such as those for 8-36 or 6-40 screws, can be drilled through with the #21 bit and used if a 10-32 spacer is not available. Most hardware stores have an assortment of aluminum spacers.)

2. When drilling the rod, you MUST fully withdraw the drill bit after every 1/4" of drilling to clear chips. Do the same with the tap.

I did. I wanted a 10-32 threaded hole for mounting a cleaning jag on a quarter-inch brass ramrod. I don't have a lathe, so here's how I did it with a simple cordless drill.

THIS EXAMPLE IS FOR A 1/4" ROD. The system will work for any diameter rod so long as you correctly match the inside and outside diameters of the components used.

Process Notes:

1. Prior to drilling the rod, you must put the aluminum spacer in a vice and run the drill bit through it so as to size the inside diameter of the spacer to be the same as the drill bit. (Other size spacers, such as those for 8-36 or 6-40 screws, can be drilled through with the #21 bit and used if a 10-32 spacer is not available. Most hardware stores have an assortment of aluminum spacers.)

2. When drilling the rod, you MUST fully withdraw the drill bit after every 1/4" of drilling to clear chips. Do the same with the tap.

where did you find the spacers??

where did you find the spacers??