barebackjack

40 Cal.

- Joined

- Apr 4, 2006

- Messages

- 361

- Reaction score

- 0

What is a powder channel? Do all guns have one?

I read that to get into the "powder channel" you have to use a smaller jag or brush.

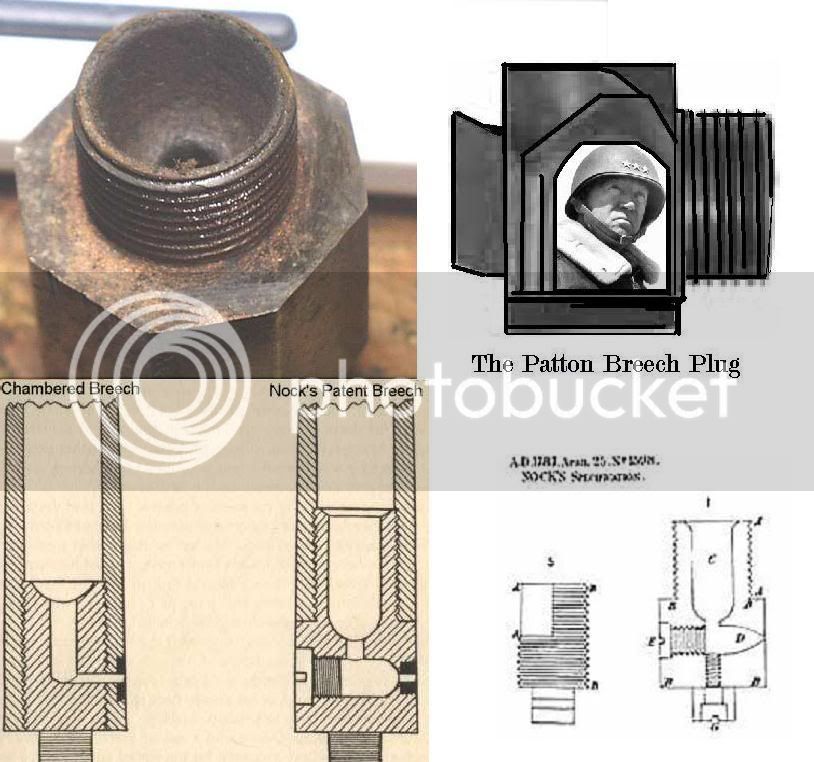

I always thought the breech of a barrel just had a squared off end, not a slightly smaller channel for powder.

They wouldnt be talking about the the channel running from the nipple to the chamber, would they? Cuz theres no way in h#ll anything but a q-tip could fit in there on my rifle.

Thanks

Boone

I read that to get into the "powder channel" you have to use a smaller jag or brush.

I always thought the breech of a barrel just had a squared off end, not a slightly smaller channel for powder.

They wouldnt be talking about the the channel running from the nipple to the chamber, would they? Cuz theres no way in h#ll anything but a q-tip could fit in there on my rifle.

Thanks

Boone