Kai Benedict

.50 caliber

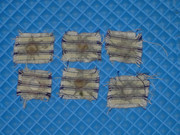

I been shooting for awhile, although I’ve question the condition the appearance of the patch. It doesn’t look burnt at all and I’m wondering what a patch should look like. Mint is white and a large hole in the center. Here’s my info if it helps . 50 cal flinter .490 round ball , 60 grains FFG and a .012 cotton patch. Lubed with mink oil. Gun built by me in 2014. Have only about 150 shots. Any help would be awesome.