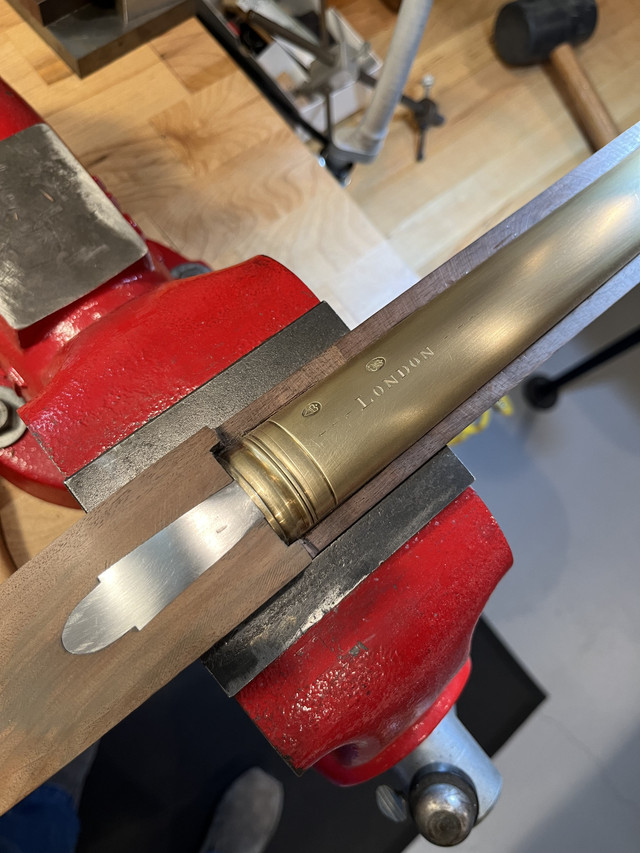

That’s really cool. I’ve been using chunks of metal and screwdrivers to use for those bending pins. I like yours way moreI was getting ready to bend the breech plug tang and was tired of doing it the same way I have always done it with a lead hammer and on a lead block. It works but is not a very controllable process in the greater scheme of things. So I stopped long enough to make these magnetically attached brass bending "bars" (for want of a better description). Brass 7/16" round stock is silver brazed to a brass arm made of 1/2" x 1/8" flat stock. A strong magnet is then screwed to the other end of the arm. These can be positioned easily on the vise and allow complete control of how much and where the bend occurs. Much better than whacking things with a lead hammer.

Copy of an original blunderbuss

- Thread starter davec2

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

With most of the wood removed with the ball cutter, it only took a short while to finish the barrel inlet with hand tools and a Frank Mittermeir barrel rasp I bought 50 years ago....Also got the ram rod groove and hole drilled. As noted previously, since the barrel is only a foot long, all of this goes much quicker than it does on a long rifle....

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

- Joined

- Jun 17, 2019

- Messages

- 8,760

- Reaction score

- 10,339

Will be nice! BTW, nothing is more uglier that the current Traditions 'blunderbuss', with apologies to anyone having one; JMHO. Overpriced, too!

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

- Joined

- Nov 26, 2005

- Messages

- 5,320

- Reaction score

- 11,466

Hi Dave,

Isn't it a shame that so much of that nice wood ends up as dust on the floor. Nice job! It is looking great.

dave

Isn't it a shame that so much of that nice wood ends up as dust on the floor. Nice job! It is looking great.

dave

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

David,Hi Dave,

Isn't it a shame that so much of that nice wood ends up as dust on the floor. Nice job! It is looking great.

dave

Yes it is a shame. I said the same thing to an old fellow I used to buy exotic hardwood from. He responded that he just looked at the positive side of how much we saved by making beautiful things out of it.

Best,

Dave C

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

Silver brazed (with brass colored alloy) a piece of sheet brass on the rear ram rod pipe and then shaped it. With a lower fusing silver braze, I soldered the tab on the top of both pipes. Inletted the pipes and drilled for the retention pins. (Rear ram rod pipes are my least favorite part of building a gun.....have I mentioned that before  )

)

- Joined

- Mar 7, 2007

- Messages

- 739

- Reaction score

- 2,424

Some continuing work......

Once the lock is inlet, I shape the lock molding roughly. Once that is done, I can drill for the lock bolts. With the lock bolt locations as reference. I use a piece of clear plastic sheeting to trace the lock molding outline and then transfer it to the side plate area. I know there is no absolute requirement for the two sides to match, but I like to get them as close as possible and this method works well.

Preparing the trigger, trigger plate, and trigger pivot housing.....

Side plate layout and start of the tedious inletting.......

Trigger guard layout, trigger housing, and trigger guard inletting......

Started the final shaping of the butt stock.....

Once the lock is inlet, I shape the lock molding roughly. Once that is done, I can drill for the lock bolts. With the lock bolt locations as reference. I use a piece of clear plastic sheeting to trace the lock molding outline and then transfer it to the side plate area. I know there is no absolute requirement for the two sides to match, but I like to get them as close as possible and this method works well.

Preparing the trigger, trigger plate, and trigger pivot housing.....

Side plate layout and start of the tedious inletting.......

Trigger guard layout, trigger housing, and trigger guard inletting......

Started the final shaping of the butt stock.....

EXCELLANT!

Brokennock

Cannon

Fabulous. Thank you for the update.Some continuing work......

Once the lock is inlet, I shape the lock molding roughly. Once that is done, I can drill for the lock bolts. With the lock bolt locations as reference. I use a piece of clear plastic sheeting to trace the lock molding outline and then transfer it to the side plate area. I know there is no absolute requirement for the two sides to match, but I like to get them as close as possible and this method works well.

Preparing the trigger, trigger plate, and trigger pivot housing.....

Side plate layout and start of the tedious inletting.......

Trigger guard layout, trigger housing, and trigger guard inletting......

Started the final shaping of the butt stock.....

Enjoyed reading through this post, wonderful craftsmanship.

Similar threads

Wanted - parts

WTB Blunderbuss barrel

- Replies

- 0

- Views

- 77

- Replies

- 28

- Views

- 1K

- Replies

- 26

- Views

- 3K

- Replies

- 16

- Views

- 1K

- Replies

- 12

- Views

- 755