If ya'll was sittin around cuttin little round circles out of pillow case cloth with scissers to use in a .54cal. barrel how big a hole would you cut in the cloth. I'm thinking since they are custom made 1-1/2" round should work better than the store bought size. I'm putting bore butter on them and nukin for lube.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Round Patches

- Thread starter Hoyt

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

amccall

40 Cal.

Cutting circle patches with scissors, my hat is off to you. :hatsoff:

I will either cut my pathces at the muzzle or use a paper cutting board with a blade and straight edge and cut about 1 1/4 inch square. A 1 1/2 inch patch will not make a difference a little bigger patch shoots the same as patch cut at the muzzle.

I will either cut my pathces at the muzzle or use a paper cutting board with a blade and straight edge and cut about 1 1/4 inch square. A 1 1/2 inch patch will not make a difference a little bigger patch shoots the same as patch cut at the muzzle.

MikeChapin

58 Cal.

- Joined

- Apr 5, 2005

- Messages

- 2,183

- Reaction score

- 6

Seems like a lot of work. Square and octagon patches work as well and are not nearly as much work. I use round patches cut with a 1 3/8 hole saw that I ground the teeth off and put an edge on. That size works for .50 through .58. I just chuck it up in the drill press and cut patches until I get get enough or run out of cloth.

Before that I just used square cuts.

Before that I just used square cuts.

jtmattison

70 Cal.

- Joined

- Mar 17, 2004

- Messages

- 4,686

- Reaction score

- 9

I use my wifes rotary cutter with the measure marks on it, the kind that cuts a straight line. I cut the ticking into 1 1/4 inch squares for my .54. You can leave them square, it don'e effect accuracy or you can cut them round. I cut them round by sandwiching 10-15 square patches between two 1 1/4 inch metal washers and cutting off the excess with scissors. It's a bit tedious but what else is there to do when there's a blizzard outside? I cut about 1,000 at a time and they last a good while.

Huntin

Huntin

He-Bear,

Great idea, so do you pre-lube after they are cut or just prior to shooting. I usually cut in strips, put

aside and the day before shooting will lube both sides of

the strips then roll up and put in 35mm film canisters till

shooting time then take stips out a cut what i need off the strips at the barrel. I use Moose-Snot as lube that i make

myself and have never had a problem using it.

snake-eyes

Great idea, so do you pre-lube after they are cut or just prior to shooting. I usually cut in strips, put

aside and the day before shooting will lube both sides of

the strips then roll up and put in 35mm film canisters till

shooting time then take stips out a cut what i need off the strips at the barrel. I use Moose-Snot as lube that i make

myself and have never had a problem using it.

snake-eyes

- Joined

- Aug 25, 2003

- Messages

- 6,527

- Reaction score

- 1,506

I bought a hole saw blade of appropriate size. Mounted it on the end of an oak dowel, Ground the teeth off, beveled the outside to an edge and sharpened it. I put an iron plumbing union over the other end to keep it from splitting. Depending on how many folds I make with the cloth, I get 4 to 6 patches per hammering with a wood mallet. If you do this, use oak or other hardwood as an anvil. Soft wood allows the cloth to go into the wood and you get a poor cut. You will often have to trim a patch or two from each cut that did not quite separate, but this is a very minor thing, rangeing from a few threads to maybe a quarter inch that just did not cut through. It is quite fast and easy to do them this way.

I use my wifes rotary cutter with the measure marks on it, the kind that cuts a straight line. I cut the ticking into 1 1/4 inch squares for my .54. You can leave them square, it don'e effect accuracy or you can cut them round. I cut them round by sandwiching 10-15 square patches between two 1 1/4 inch metal washers and cutting off the excess with scissors. It's a bit tedious but what else is there to do when there's a blizzard outside? I cut about 1,000 at a time and they last a good while.

Huntin

Agree...so far, I've just used precut/prelubed pillow ticking patches I buy in large quantities when I find a good deal, etc...but if I was going to cut my own patches, I'd definitely cut and use them square.

There's no difference between round & square, and it's so fast on my Wife's cutting board with that rotary cutter...plus, knowing her, she'd just knock them out for me like she does when she cuts up a few hundred flannel cleaning patches for me.

What is the recipe for Moose-Snot?

I tried the 50/50 Murphyhol the last time to the range and had a heck of a time loading. It took a wooden mallet to stare the ball, and I thought I was going to break my ramrod before it was half way down. Ronnie...

Ronnie...

I tried the 50/50 Murphyhol the last time to the range and had a heck of a time loading. It took a wooden mallet to stare the ball, and I thought I was going to break my ramrod before it was half way down.

What is the recipe for Moose-Snot?

I tried the 50/50 Murphyhol the last time to the range and had a heck of a time loading. It took a wooden mallet to stare the ball, and I thought I was going to break my ramrod before it was half way down.Ronnie...

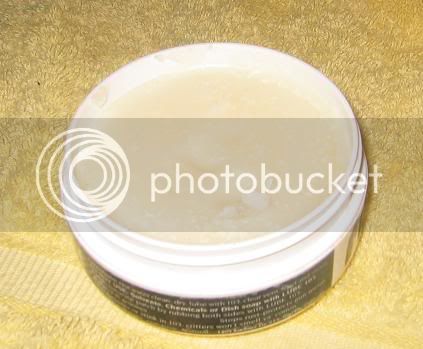

Here is a picture of some I just made 2 days ago ..have not tried it yet ... but here is the recipe from elsewhere on the site.. ::

Moose Snot is a homemade concoction derived from our very own Stumpkiller...

It goes as follows:

Stumpy's Moose Snot (by: Stumpkiller)

A premium multi-shot between wiping (10+) patch lube stable over a wide temperature range.

SPECIFICALLY designed for use of patched round balls in a loading block

Beeswax 2 oz.

Castor Oil 8 oz.

Murphy's Oil Soap 1 oz.

Heat beeswax in a soup can set a pot of water. ( A double-boiler. I keep my beeswax in a one pound coffee can and measure out what I need by melting it and pouring it into measuring cups). Add just enough water so the inner can does not begin to float (should be just short of the lube level in the can). Heat the water to a low boil. In a separate can, add the castor oil and Murphy's oil soap (cold). Once the beeswax is melted, swap the castor oil can in the pot of water for the beeswax. Add the beeswax to the oils. It will clump up. Stir with an ice tea spoon as the mixture heats up. When it fully melts there will be a scum that floats to the top and just won't mix in. Be patient. DO NOT COOK THE MIXTURE. Once the solids are dissolved there is no need to heat further. Skim the scum off. Remove the mix from the heat and wipe the water off the outside (so it won't drip into the container when you pour it out). FINAL TOP SECRET STEP: Add a teaspoon of Murphy's Oil Soap and stir vigorously. This last step makes the lube frothy and smooth - really adds to the appearance; though it doesn't seem to matter to the function of the lube. Clamp the can in the jaws of a vice-grip pliers and pour into the waiting tins. Allow to cool a half hour.

Note: it if is a hinged tin - line the edge that has the hinges with a strip of aluminum foil so it doesn't ooze out before it cools.

Davy

amccall

40 Cal.

I usually cut the squares and group them up in a stack. I then put them in a vise to hold them and soak them with moose milk and leave them in the vise over night. I then soak them again and squeeze the excess off with the vise and put them in a plastic bag or whatever will keep them moist. If they dry out I put a little moose milk on them and they are ready to go. I also do the strips like what you do, it all works out in the end.

I have seen someone use an old deep fryer to lube patches, he filled the basket half full and submerged them in the melted lube for a minute or two, then removed the basket and pressed the excess lube out with an old bottle's base...

He claimed the heated lube would penetrate the patch's fibers better, he also marked the deep fryer so no one would use it by mistake...

He claimed the heated lube would penetrate the patch's fibers better, he also marked the deep fryer so no one would use it by mistake...

- Joined

- Oct 21, 2004

- Messages

- 2,703

- Reaction score

- 2

he also marked the deep fryer so no one would use it by mistake...

I washed out a "no stick" pan that I had heated up some Wonder Lube in and left it by the sink. Next morning I scrambled some eggs for my wife, forgetting that the pan, although clean, might have some "residual flavor" :shocking: :youcrazy:. She took one bite and made an awful face :shake:. Whoops! :redface: That pan is now dedicated to patch-lubing and rests in a drawer with my pillow ticking, scissors, etc.

I do mine like John Hinnant suggested .. lube em, put them ina glass mason jar out in the car for a coupla days in tha Texas heat! :shocking: Thta'll do er I guarantee! And because its in a closed container .. no loss of moisture! Saturates the patches jest fine! :m2c: Ol John ... He ain't steered me wrong yit! Course that 80 years of shootin experince heza got don hurt nuthin neether! :crackup:

Davy

Davy

Guest

I made some of that Moose snot and mine came out more of a grey color. It is somewhat fragrant with the Murphys oil soap in it. I am wondering if the color difference from mine and what I see in the picture is because the beeswax I used was raw beeswax, not the nice filtered stuff. I don't see any problem with it. Poured up nice and neat in a small throat lozenge hinged tin, and it set up fairly quickly. The nice thing about it is when you run a patch over it it leaves a nice even film.. you don't end up pushing a whack of 'grease' down the barrel. Thanks.

- Joined

- Aug 25, 2003

- Messages

- 6,527

- Reaction score

- 1,506

A year or few back, the Bevel brothers experimented with square vs round patches and found that the round are slightly more accurate. Best I recall, they had a well known target shooter explain why, but I do not remember what he had to say.

Similar threads

- Replies

- 14

- Views

- 978

Latest posts

-

-

-

-

-

-

-

-

-

Anybody here proficient in making Plains war shirts? (Need help)

- Latest: Flintlock Fellow