Anyone know where I could send a New Englander barrel to have this done? I would also have to have the under rib shortened and a new dovetail cut for the front site. I have two of these and the one that has the false muzzle does not shoot as well as the older one with a normal muzzle. And that one is very corroded in the bore from the previous owner who thought you did not have to clean as he was using TC bore butter and it would season the barrel so you did not have to clean it. And he used Pyrodex so that made it even worse. But it cleaned up and it shoots well.

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cut off TC quick load muzzle

- Thread starter tomme boy

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have a muzzleloader barrel that I wanted to have cut down and I found a local machine shop that did the work for me.

Call around to any gun shops in your area and ask where they have any gun work done.

Call around to any gun shops in your area and ask where they have any gun work done.

As suggested, a good machinist or gunsmith can do it. However, I have often found it is possible to buy gunsmithing tools and do it yerself for less cost than hiring someone. And, you still have the tool left over for next time or charge to do it for others.

leadhoarder

45 Cal.

- Joined

- Nov 27, 2020

- Messages

- 995

- Reaction score

- 1,656

Rebore it to a larger caliber.

- Joined

- Jan 31, 2009

- Messages

- 13,036

- Reaction score

- 7,296

Mine was a .54 with the so called quick load muzzle. It drew a major vacuum.Anyone know where I could send a New Englander barrel to have this done? I would also have to have the under rib shortened and a new dovetail cut for the front site. I have two of these and the one that has the false muzzle does not shoot as well as the older one with a normal muzzle. And that one is very corroded in the bore from the previous owner who thought you did not have to clean as he was using TC bore butter and it would season the barrel so you did not have to clean it. And he used Pyrodex so that made it even worse. But it cleaned up and it shoots well.

My solution was to have it relined to .458" bore diameter, .470" groove, and a 24" twist to shoot bullets as dropped from 45-70 molds.

Of course I might use a might bit more powder than those brass cartridge guns but hey, when you roll your own you make 'em suit what you want to do.

- Joined

- Jul 15, 2007

- Messages

- 1,994

- Reaction score

- 637

There's no need to pay a gunsmith to shorten a round barrel. It's a simple job you can do at home with hand tools.

Here's how I went about it.

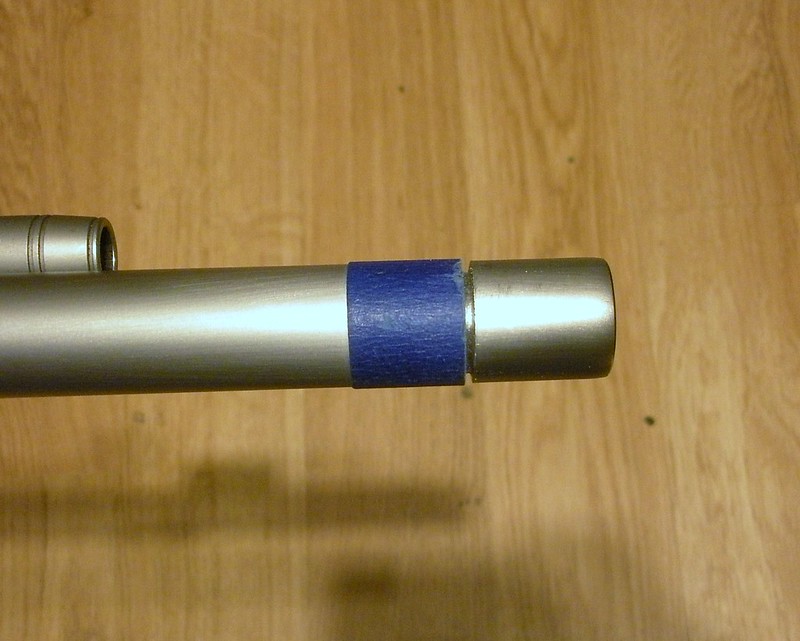

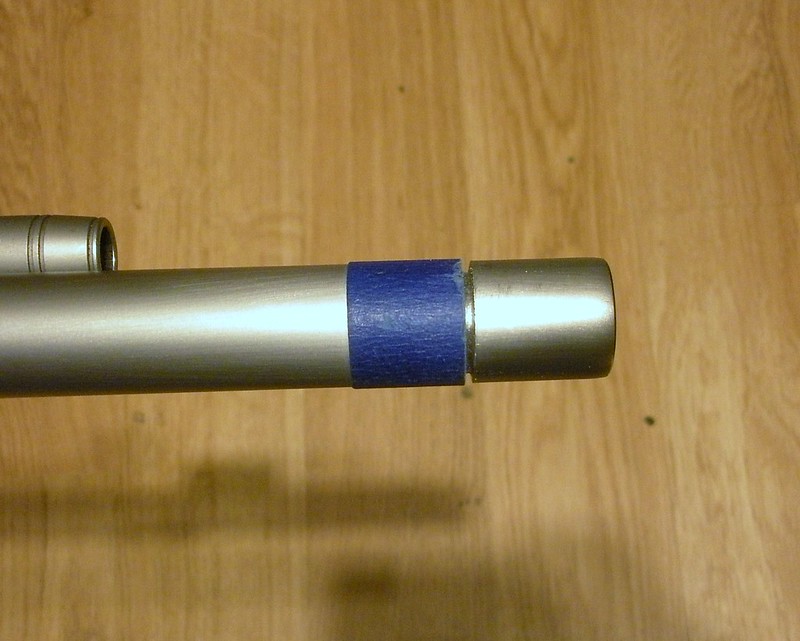

The first step was to mark the barrel for the cut. I used a copper tubing cutter to do that. These things are about $8 from Ace Hardware.

It made a nice little shallow groove around the barrel perfectly square to the bore.

Then I used a fine cut six-inch three corner file to carefully deepen the groove, laying the barrel across my lap and rotating it slowly as I filed.

I wanted a groove deep enough to serve as a starting guide for a hack saw blade.

Then I wrapped the barrel with tape to protect it from any slips when I went at it with the hack saw blade.

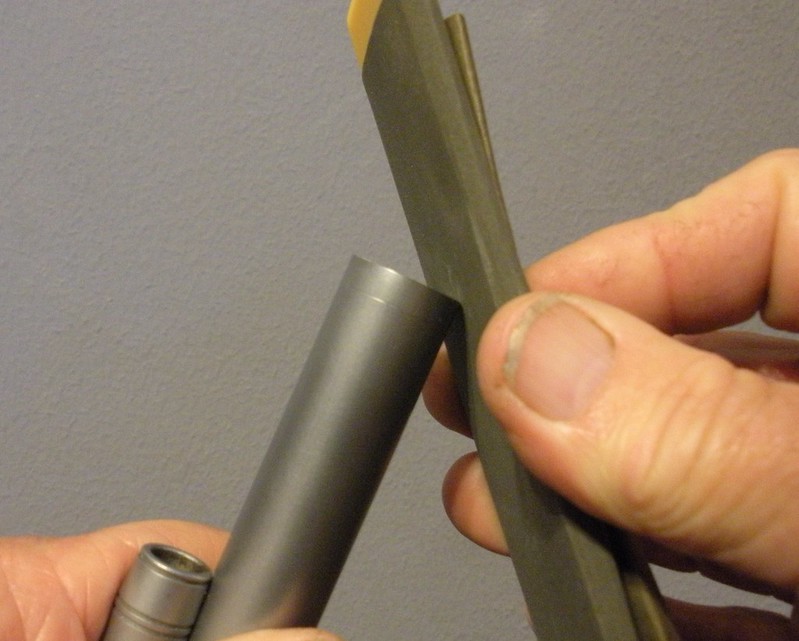

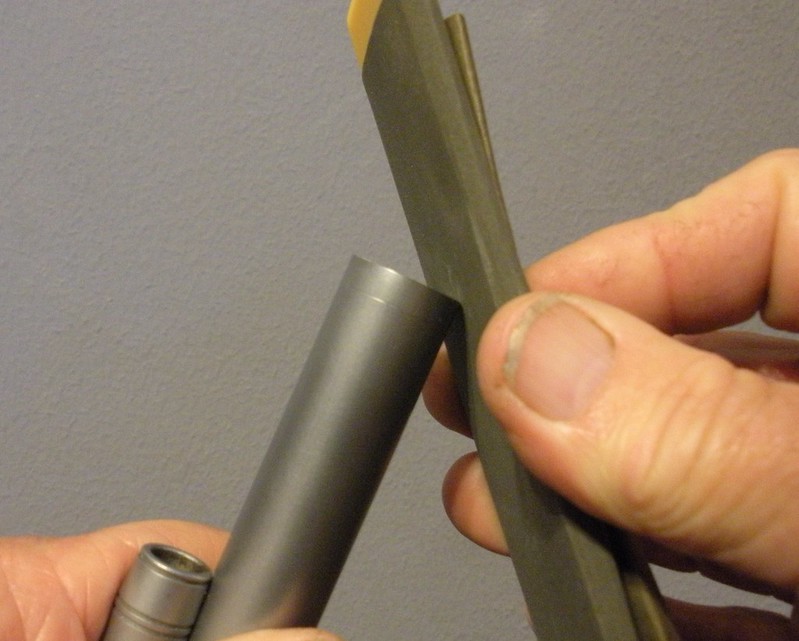

With the barrel across my lap once again, I began the cut using a new 32 tooth per inch fine cut hack saw blade held in my hand. I could probably have mounted the blade in a handle, but figured I would have more control holding the blade. I started off with very light cuts, rotating the barrel as I went.

Here’s what it looked like after about ten minutes of careful work.

It was going slowly, but nice and even. I could probably have mounted the blade in a handle at this point and proceeded at a faster and easier rate. But I was in no hurry and stuck with the handheld blade. It took longer to get all the way through but I ended up with a nice even cut.

Then I began dressing the face of the muzzle with light strokes of the fine three corner file, making sure to keep the file flat and rotating the barrel as I progressed.

It didn’t take too long to remove all of the lines and scratches left by the saw blade.

I then used 240 grit emery paper backed by a flat piece of aluminum to continue dressing the muzzle flat and smooth, keeping it flat against the muzzle and using a circular motion. I followed the 240 grit paper with a final polish of 400 grit paper.

Once it was flat and smooth I used the 240 grit, then the 400 grit the to slightly chamfer the outside edge, removing the sharp corner.

Then used one-inch squares of 240 grit and 400 grit paper and my thumb to slightly chamfer the inside of the muzzle

The final product was quite satisfactory. I don’t know how a smith could have done any better.

As you can see, I managed to keep everything flat and square.

By the way, I did all of the work sitting on a chair in my man cave.

__________________

Here's how I went about it.

The first step was to mark the barrel for the cut. I used a copper tubing cutter to do that. These things are about $8 from Ace Hardware.

It made a nice little shallow groove around the barrel perfectly square to the bore.

Then I used a fine cut six-inch three corner file to carefully deepen the groove, laying the barrel across my lap and rotating it slowly as I filed.

I wanted a groove deep enough to serve as a starting guide for a hack saw blade.

Then I wrapped the barrel with tape to protect it from any slips when I went at it with the hack saw blade.

With the barrel across my lap once again, I began the cut using a new 32 tooth per inch fine cut hack saw blade held in my hand. I could probably have mounted the blade in a handle, but figured I would have more control holding the blade. I started off with very light cuts, rotating the barrel as I went.

Here’s what it looked like after about ten minutes of careful work.

It was going slowly, but nice and even. I could probably have mounted the blade in a handle at this point and proceeded at a faster and easier rate. But I was in no hurry and stuck with the handheld blade. It took longer to get all the way through but I ended up with a nice even cut.

Then I began dressing the face of the muzzle with light strokes of the fine three corner file, making sure to keep the file flat and rotating the barrel as I progressed.

It didn’t take too long to remove all of the lines and scratches left by the saw blade.

I then used 240 grit emery paper backed by a flat piece of aluminum to continue dressing the muzzle flat and smooth, keeping it flat against the muzzle and using a circular motion. I followed the 240 grit paper with a final polish of 400 grit paper.

Once it was flat and smooth I used the 240 grit, then the 400 grit the to slightly chamfer the outside edge, removing the sharp corner.

Then used one-inch squares of 240 grit and 400 grit paper and my thumb to slightly chamfer the inside of the muzzle

The final product was quite satisfactory. I don’t know how a smith could have done any better.

As you can see, I managed to keep everything flat and square.

By the way, I did all of the work sitting on a chair in my man cave.

__________________

I have a small lathe I can part it off with. But no way to cut a new dovetail for the front sight. That is the main problem. As I don't work anymore I don't have access to a Bridgeport mill anymore or I would do all of this myself at work. I had a full machine shop connected to out maintenance crib. I used it all the time when things were slow and had nothing else to do. All the guys i know there are now retired as well so I can't just stop by anymore.

I have a friend that builds turbo engines and parts. I think I will stop by and see what tools he has. If not, what about Track of the wolf? I see they do this.

I have a friend that builds turbo engines and parts. I think I will stop by and see what tools he has. If not, what about Track of the wolf? I see they do this.

X Y vice and drill press can get the cut out for the dovetail then a tri file smoothed on one side for the angle.I have a small lathe I can part it off with. But no way to cut a new dovetail for the front sight. That is the main problem. As I don't work anymore I don't have access to a Bridgeport mill anymore or I would do all of this myself at work. I had a full machine shop connected to out maintenance crib. I used it all the time when things were slow and had nothing else to do. All the guys i know there are now retired as well so I can't just stop by anymore.

I have a friend that builds turbo engines and parts. I think I will stop by and see what tools he has. If not, what about Track of the wolf? I see they do this.

You can also buy a jig for cutting the dovetail slot from Deer Creek or Dixie.

But there is a way. If I can do it so can you. You will need a hacksaw, small flat file and a triangle file with one side ground smooth. Start by marking where you want the sight. Make marks for both sides of the dovetail. Using the hacksaw cut a series of slots into the metal were the sight is to go. Be careful not to cut too deeply The eyeball method works very well. Then using the flat file cut the remaining standing pieces down to the bottom of the hacksaw cuts. You can use the flat file to smooth up the bottom of your cut but that is not really necessary for looks as the sight will cover it. Then using the triangle file make your undercuts on each side. The ground smooth side of the file is to be on the bottom and is smooth so as to not make you cut too deep. Trying the sight and cutting until it fits is the slowest part of the job. About an hour of work.But no way to cut a new dovetail for the front sight

Similar threads

- Replies

- 28

- Views

- 2K