- Joined

- Jun 12, 2005

- Messages

- 8,027

- Reaction score

- 1,031

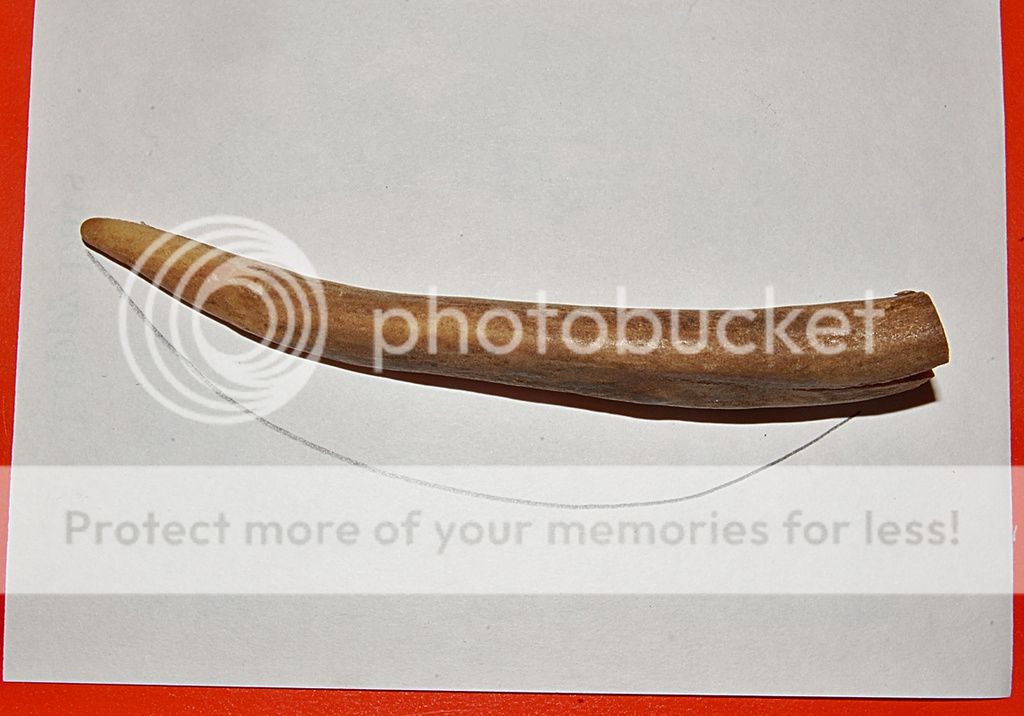

I get mine from the local pet store - they're about five buck each... they're labeled as elk tines, but look like large deer - can't really tell, not having much experience with elk ... I use a dremel and a grout bit (it's what happened to be in the tool) to get the inner bits out, then I go to a drill bit ... a piece of 320 grit wrapped in a dowel gets the inside smooth, and with a bit of 'tinkering,' you adjust the volume to what you want and, ta da, there you go...

if you don't have a Dremel, there are similar items to be had at Harbor Freight ... here's one (a ten dollar cheapie): http://www.harborfreight.com/power-tools/rotary-tools/rotary-tool-kit-80-pc-69451.html

or, if you want something a bit more 'muscular,' and you have a bigger wallet: http://www.harborfreight.com/power...riable-speed-rotary-tool-kit-31-pc-60713.html

as a general rule, I keep spinning power tools away from gun stuff - such things can get you into trouble much faster that they can get you out of trouble, but with antler stuff, if you go slow and are careful, you should be OK ...

make one for each gun you own, of course

also, watch the dust - I doubt that this is something you want to inhale or ingest, and if you don't already, wear safety glasses.

good luck with your project!

if you don't have a Dremel, there are similar items to be had at Harbor Freight ... here's one (a ten dollar cheapie): http://www.harborfreight.com/power-tools/rotary-tools/rotary-tool-kit-80-pc-69451.html

or, if you want something a bit more 'muscular,' and you have a bigger wallet: http://www.harborfreight.com/power...riable-speed-rotary-tool-kit-31-pc-60713.html

as a general rule, I keep spinning power tools away from gun stuff - such things can get you into trouble much faster that they can get you out of trouble, but with antler stuff, if you go slow and are careful, you should be OK ...

make one for each gun you own, of course

also, watch the dust - I doubt that this is something you want to inhale or ingest, and if you don't already, wear safety glasses.

good luck with your project!

Last edited by a moderator: