chawbeef

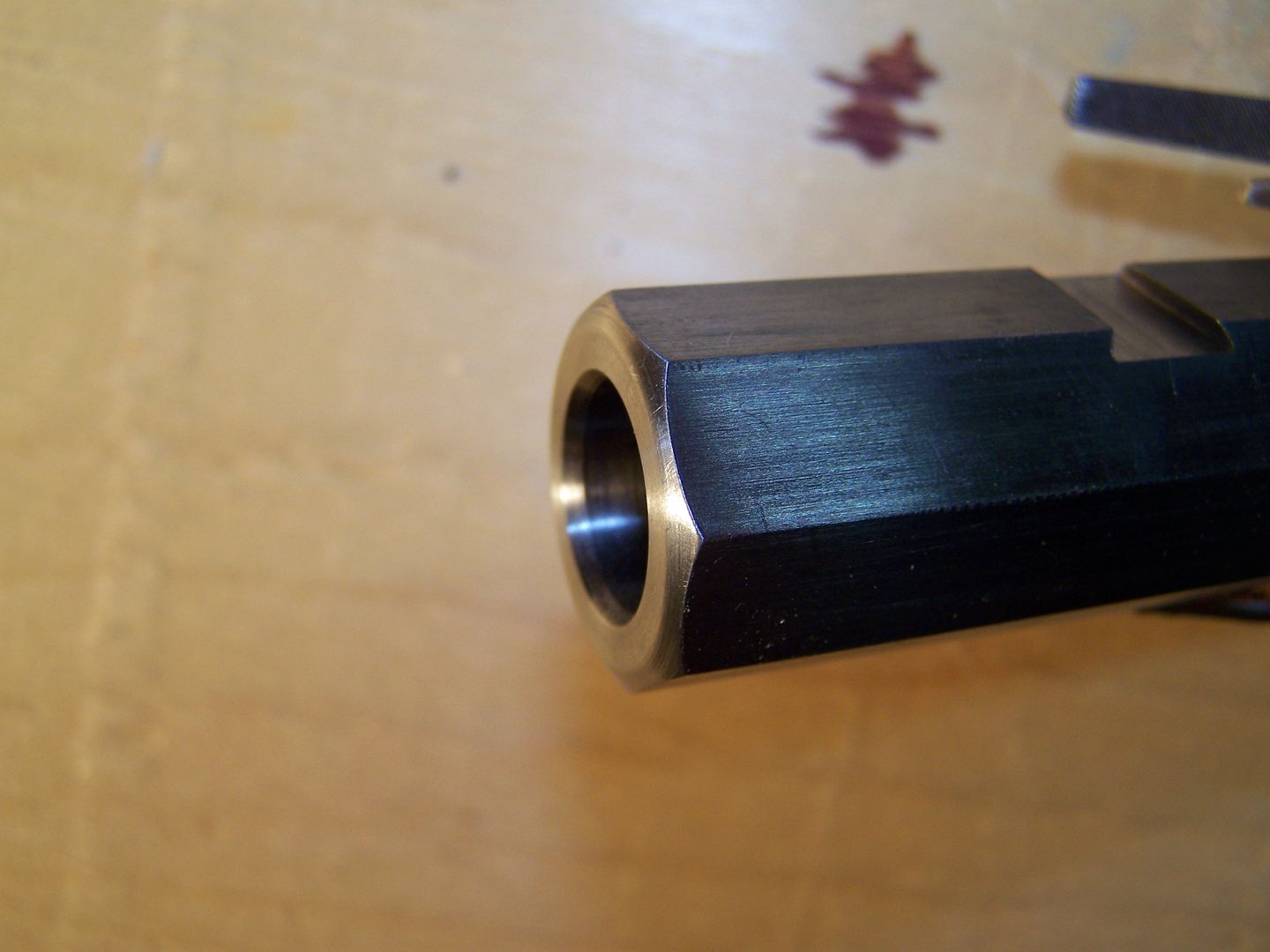

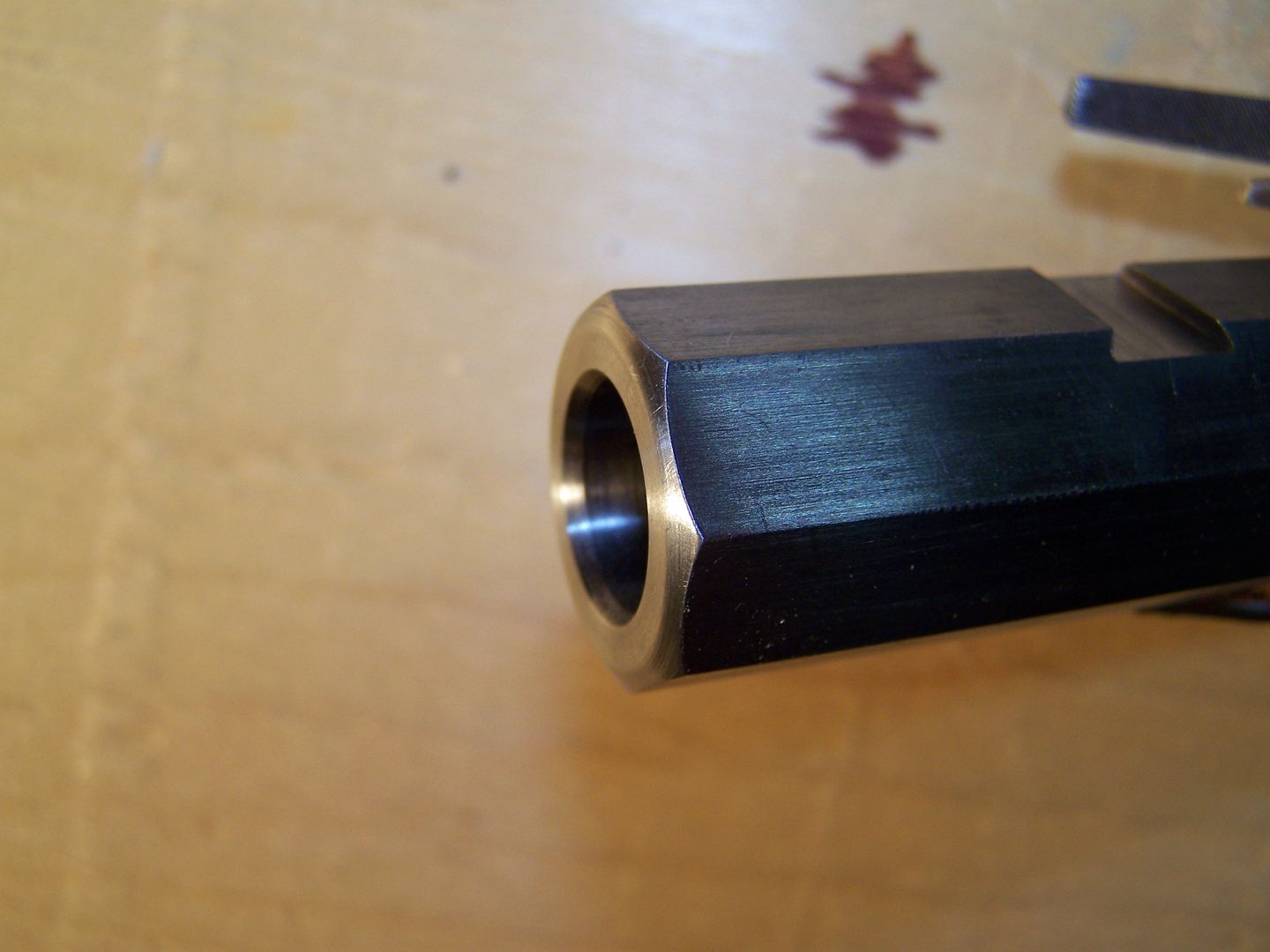

40 Cal.

First time doing this. I milled parallel slots in my barrel for front and rear sights and plan to finish dove tails with a "safe" file. I also used a lathe to part off my barrel to length, chamfer the inside and out side muzzle end and cone the bore to approx. 1 inch depth. I used a short length of half in dia. drill rod in the bore to dial in the 4 jaw chuck to less than .0005 in. Hope the pics wo[URL=http://s178.photobucket.com/user/boogaloo_2007/media/146_3432.jpg.html]

[/URL]rk........Daniel

[/URL]rk........Daniel