Well, I've heard of people dropping roundballs out of their molds into a bucket of water.

I've always just dropped them onto a couple of soft t-shirts.

Well, I got a bit inquisitive and decided to do some experimenting.

I got my Lee double cavity .490 mould out, warmed up and seasoned. I heated 5 lbs of lead to a "9" in a Lee Pro-20 pot.

I cast ten balls that I set aside.

Then, I cast 20 balls in a row and dropped them onto two XL t-shirts that were crumbled up on the bench.

Then, I cast 20 more balls and dropped them into a 5 gallon bucket of water. Each ball made a "thunk" when it hit bottom.

I let the balls cool off for a while then mic'd each for it diameter and weighed each one.

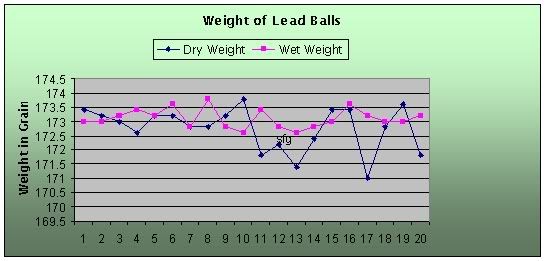

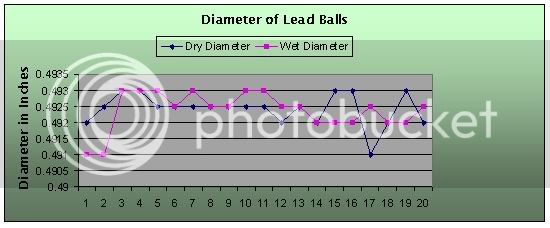

I made two charts, one for weight and one for diameter. "Wet" identifies balls dropped in the water. "Dry" identifies balls dropped on T-Shirts.

Well the average weight and diameter was only a thousanth or so off, the "wet" balls are more consistent in their weight and diameter.

Then, I took 2 wets and 2 drys and did a hardness test. I took a wet and a dry and placed them in a vice, the two balls against eachother and smashed them with the vice. The dry balls had a larger deformation in them meaning the wet balls were harder.

So, from my limited experiment, dropping balls directly from the mold into a bucket of water creates a more uniform run of balls.

I've always just dropped them onto a couple of soft t-shirts.

Well, I got a bit inquisitive and decided to do some experimenting.

I got my Lee double cavity .490 mould out, warmed up and seasoned. I heated 5 lbs of lead to a "9" in a Lee Pro-20 pot.

I cast ten balls that I set aside.

Then, I cast 20 balls in a row and dropped them onto two XL t-shirts that were crumbled up on the bench.

Then, I cast 20 more balls and dropped them into a 5 gallon bucket of water. Each ball made a "thunk" when it hit bottom.

I let the balls cool off for a while then mic'd each for it diameter and weighed each one.

I made two charts, one for weight and one for diameter. "Wet" identifies balls dropped in the water. "Dry" identifies balls dropped on T-Shirts.

Well the average weight and diameter was only a thousanth or so off, the "wet" balls are more consistent in their weight and diameter.

Then, I took 2 wets and 2 drys and did a hardness test. I took a wet and a dry and placed them in a vice, the two balls against eachother and smashed them with the vice. The dry balls had a larger deformation in them meaning the wet balls were harder.

So, from my limited experiment, dropping balls directly from the mold into a bucket of water creates a more uniform run of balls.