- Joined

- Nov 26, 2005

- Messages

- 5,246

- Reaction score

- 11,027

Hi,

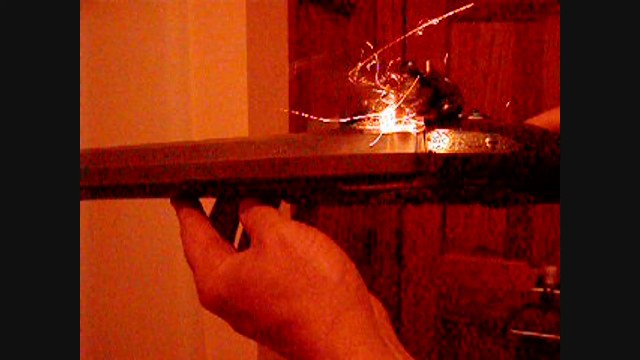

I want to show these photos that demonstrate what I consider good performance in a flintlock. The lock is a Chamber round-faced English lock (which I consider the best lock commercially made today). However, it was tuned by me, springs balanced (frizzen spring opens at 30% of the force required to pull flintcock to full), and the frizzen was case hardened. The first photo shows sparks from a fresh sharp flint:

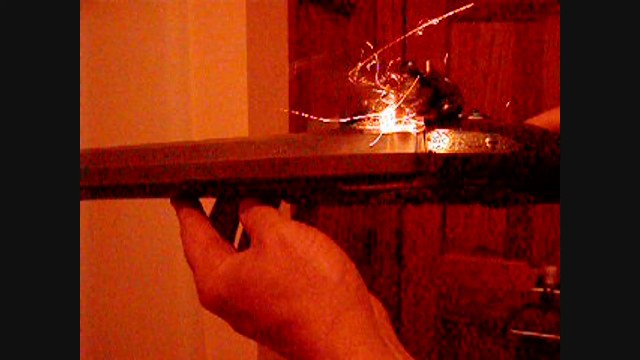

Now I turn that flint around so the dull blunt end faces the frizzen:

and fire:

Then I coat the frizzen and flint with inletting black to simulate heavy thick greasy fouling on a humid day and fire:

Then I picked up a small piece of quartz from my driveway:

and fired:

In all cases, the lock would have ignited the powder in the pan and fired. This is what I look for in a lock. I have now fired more than 600 rounds from this rifle without a single misfire or hang fire even when it was dirty and the flint worn to a nub. I've gone through only 10 flints during that time and I replace them when they have no discernible edge not when the lock fails.

dave

I want to show these photos that demonstrate what I consider good performance in a flintlock. The lock is a Chamber round-faced English lock (which I consider the best lock commercially made today). However, it was tuned by me, springs balanced (frizzen spring opens at 30% of the force required to pull flintcock to full), and the frizzen was case hardened. The first photo shows sparks from a fresh sharp flint:

Now I turn that flint around so the dull blunt end faces the frizzen:

and fire:

Then I coat the frizzen and flint with inletting black to simulate heavy thick greasy fouling on a humid day and fire:

Then I picked up a small piece of quartz from my driveway:

and fired:

In all cases, the lock would have ignited the powder in the pan and fired. This is what I look for in a lock. I have now fired more than 600 rounds from this rifle without a single misfire or hang fire even when it was dirty and the flint worn to a nub. I've gone through only 10 flints during that time and I replace them when they have no discernible edge not when the lock fails.

dave