Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

This has been a much cussed and discussed topic for quite a while. Currently we have two separate topics going. Shooters here have such wide experiences with cut (sawn) agate that I haven't seen an explanation that satisfies me. I don't like questions that cannot be rationally tested.

So leaving emotion aside, I went back some 25+ years and began looking at experiments that began at the Gunmaking Seminar at Bowling Green KY. I have two possible theories that I want to explore sifting through numbers from those years. The article containing the data is the Journal of Historic Armsmaking Technology, Vol. IV. Jan 1991.

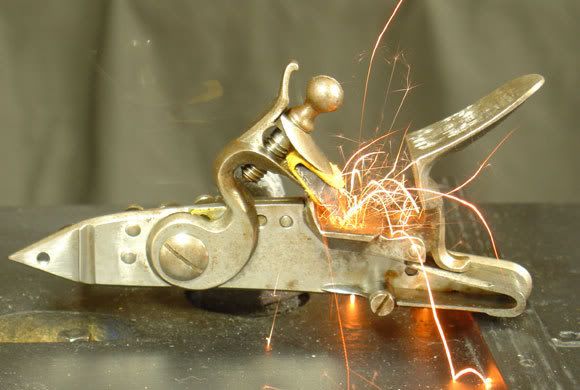

Gary Brumfield was my partner in crime at the beginning. He prodded me into this study. Thanks Gary. The lock that took most of the experimentation was a large Siler with many modifications. (We chose to limit the trials of original locks because of their value.)

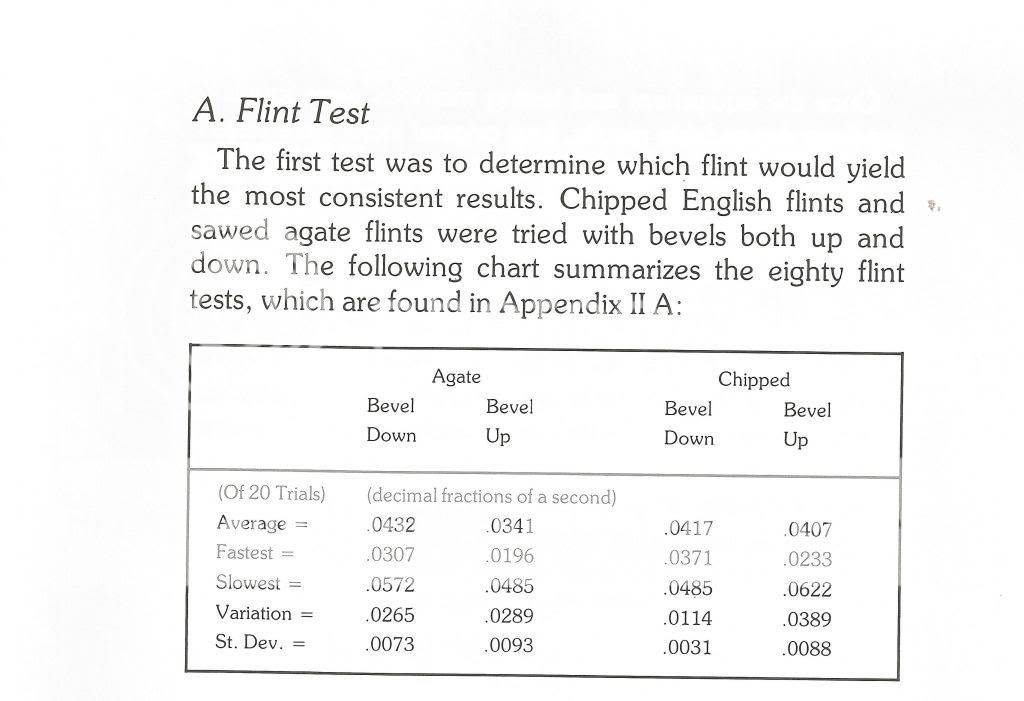

The Siler was timed in a variety of ways: multiple flints, bevels, and powders. Buried in this data, may be some answers to our current question.

I need more time to formulate my thoughts on this, but there has to be an answer in there somewhere. My gut says that frizzen hardness, stone hardness, or maybe both could be part of the answer. I need to go over some numbers.

Regards,

Pletch

PS if any of you have Vol. IV mentioned above you can see what I'm looking through.

So leaving emotion aside, I went back some 25+ years and began looking at experiments that began at the Gunmaking Seminar at Bowling Green KY. I have two possible theories that I want to explore sifting through numbers from those years. The article containing the data is the Journal of Historic Armsmaking Technology, Vol. IV. Jan 1991.

Gary Brumfield was my partner in crime at the beginning. He prodded me into this study. Thanks Gary. The lock that took most of the experimentation was a large Siler with many modifications. (We chose to limit the trials of original locks because of their value.)

The Siler was timed in a variety of ways: multiple flints, bevels, and powders. Buried in this data, may be some answers to our current question.

I need more time to formulate my thoughts on this, but there has to be an answer in there somewhere. My gut says that frizzen hardness, stone hardness, or maybe both could be part of the answer. I need to go over some numbers.

Regards,

Pletch

PS if any of you have Vol. IV mentioned above you can see what I'm looking through.