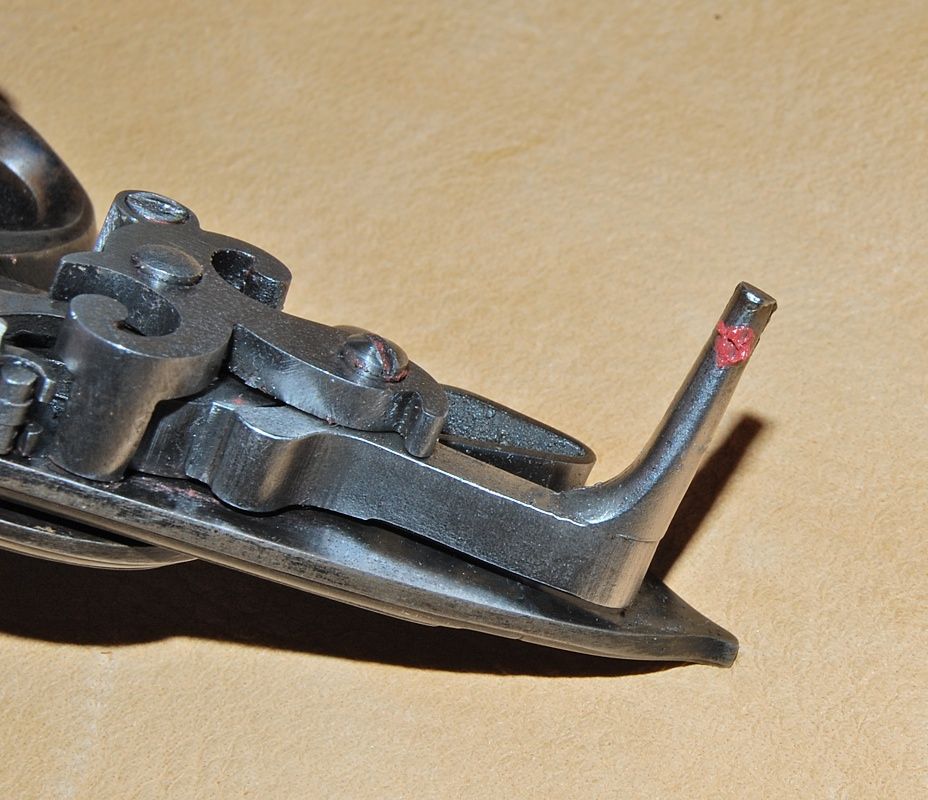

One of my flintlocks was severely damaged, both the lock and the lock mortice. After several months it's ready to be reassembled, but I have a problem. The lock is a Davis Twigg, and I sent it back for a replacement sear and sear spring, and to be put back to factory specs. It's fine, smooth as silk. The problem is that the trigger will now not quite contact the sear bar, and the gun won't fire. The gap is only less than 1/16", but since it's a finished gun, the lock and trigger positions are carved in stone. I need to close that gap. I'm considering either bending the sear arm a tad or peening the trigger to move a little metal on it. Please look at the photos and see if either option is viable, which would be less likely to cause a wreck. I tested both pieces with a small file, both can be cut, the trigger more easily.

I know you builders first advice will be to silver solder it or some such. That wouldn't be easy for me, I need something simpler, if possible..

Contact point on the trigger is in the center of the arch.

The lipstick marks the contact point on the sear arm.

All advice greatly appreciated.

Thanks,

Spence

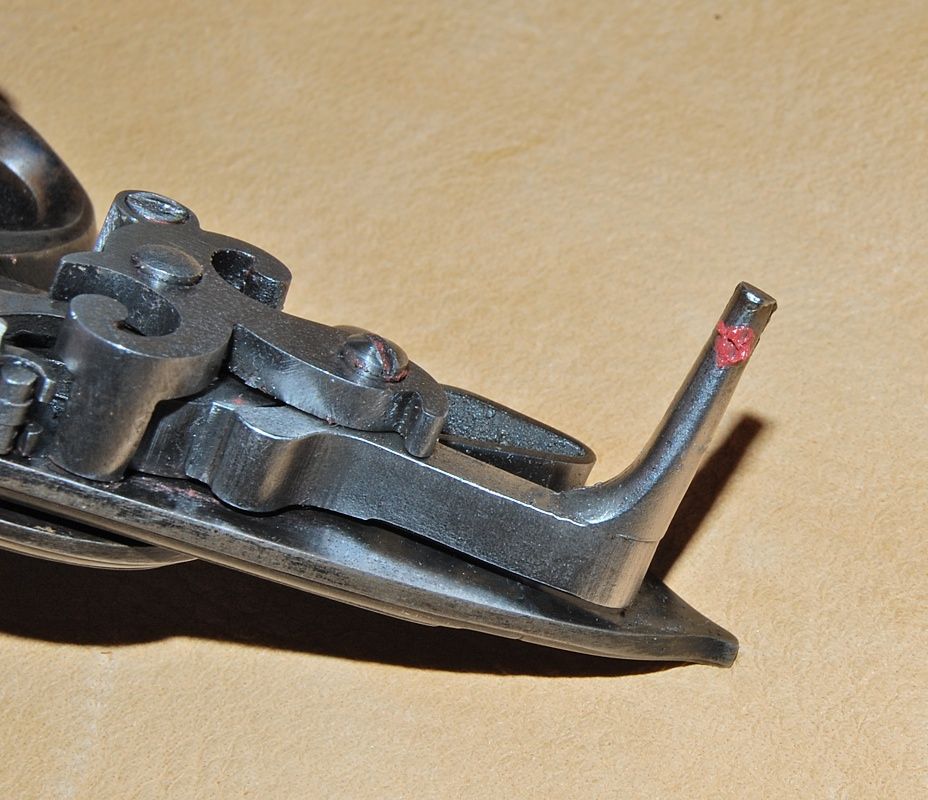

I know you builders first advice will be to silver solder it or some such. That wouldn't be easy for me, I need something simpler, if possible..

Contact point on the trigger is in the center of the arch.

The lipstick marks the contact point on the sear arm.

All advice greatly appreciated.

Thanks,

Spence