PitchyPine

69 Cal.

- Joined

- Oct 6, 2006

- Messages

- 3,418

- Reaction score

- 1

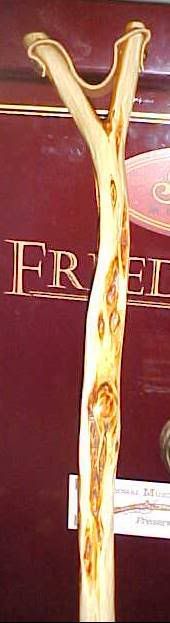

Made another this morning, all one piece and i`m not going to put a serpentine on it or pin the handle. :thumbsup:

mazo kid said:Looking good Lenn!! How did you make the bore smooth? Seems I can never drill or bore without having roughness. Emery

willisburg said:Pitchy

Looks very good!! :wink:

Willisburg

PitchyPine said:Thanks Davy, have to get a handle Friday first before firing it.

Bore is pretty smooth and is 50 cal. and five inch. deep.

Vent is 3/32 and pan 3/8ths

Hole for handle is one inch and overall length is nine inches.

Will post some fire ASAP.

Enter your email address to join: