I sometimes get an opportunity to forge a small axe and I thought it might be interesting to see the general stages of forging.

I start with a rectangular piece, the size of which is proportionate to the axe size. For a 1-1/4 lb belt axe, I use a starting bar about 1/2 inch thick X 2 inch wide X 7-1/2 inch long. I use mild steel or wrought iron since this is the body.

I forge that into the "bowtie".

Then it is forged folded.

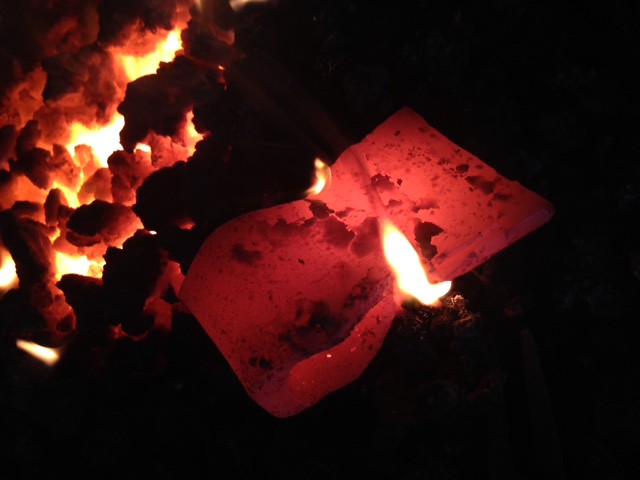

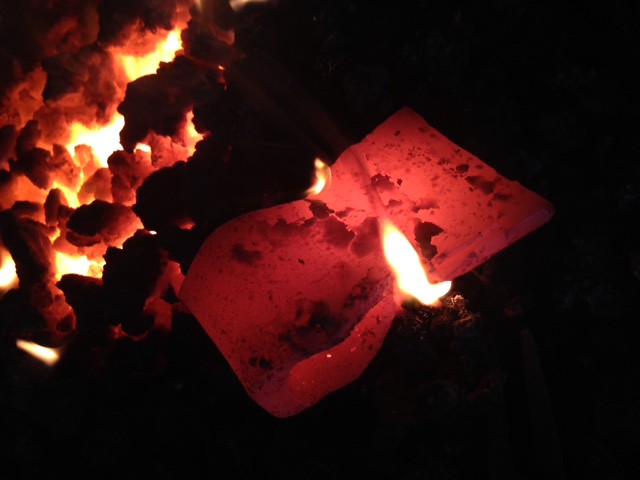

From this:

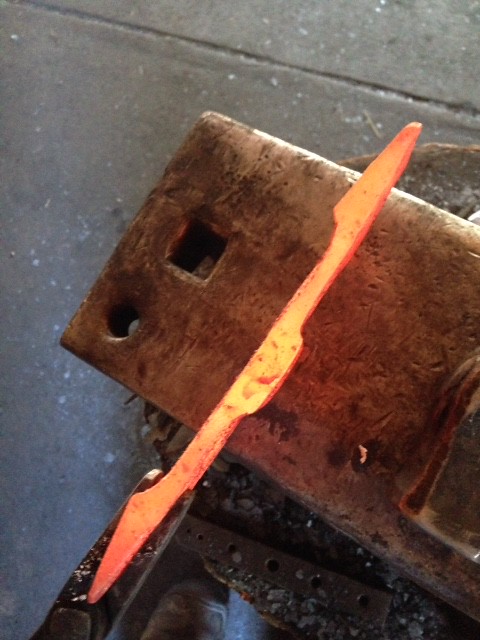

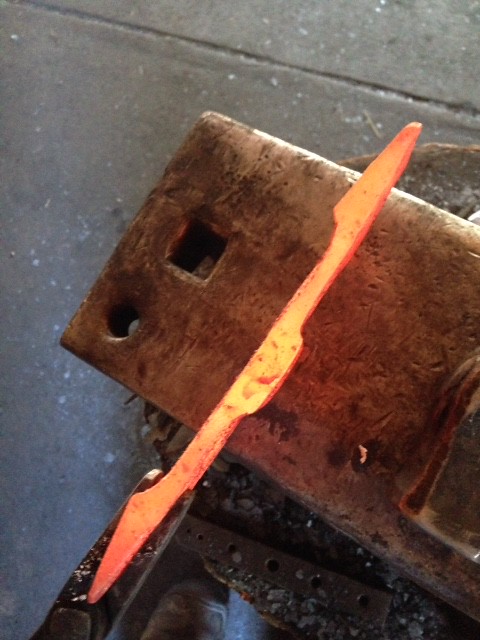

To this:

Now the steel bit is forged and sandwiched between the "jaws" and forge welded.

Fitting the bit:

The weld is made and the edge is being spread.

After the blade is spread and tapered a lot of straightening has to be done and a drift has to be inserted to shape the eye and support it during some of the last of the hammering to finish.

After heat treat, grind, and the handle is carved and fit.

There is a lot of ways to shape these to match different regional styles or periods. Hawks are made in a similar way. Plus there is the slitting and drifting method of forging them from a solid block.

I start with a rectangular piece, the size of which is proportionate to the axe size. For a 1-1/4 lb belt axe, I use a starting bar about 1/2 inch thick X 2 inch wide X 7-1/2 inch long. I use mild steel or wrought iron since this is the body.

I forge that into the "bowtie".

Then it is forged folded.

From this:

To this:

Now the steel bit is forged and sandwiched between the "jaws" and forge welded.

Fitting the bit:

The weld is made and the edge is being spread.

After the blade is spread and tapered a lot of straightening has to be done and a drift has to be inserted to shape the eye and support it during some of the last of the hammering to finish.

After heat treat, grind, and the handle is carved and fit.

There is a lot of ways to shape these to match different regional styles or periods. Hawks are made in a similar way. Plus there is the slitting and drifting method of forging them from a solid block.