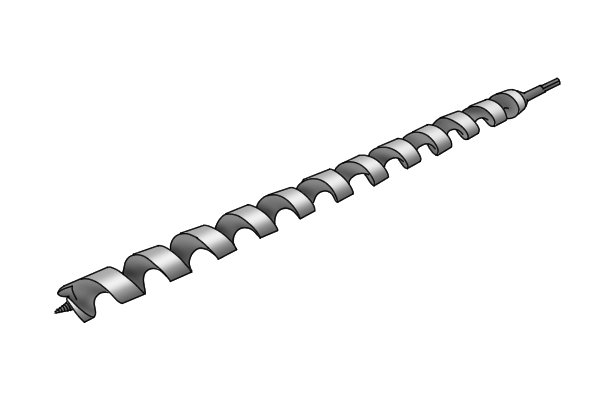

I bought a ling bit from Track and, frankly, it was the only (of many) purchases which I regret. Long story short: it didn't work as expected.

I mentioned my problem to the fellow who does body work here. He also does towing. If you ever need autobody in southeastern Vermont- Steve is the 'go to' guy - his work looks better than factory new. He looks at me like I'm the biggest dunce on the planet and asks, what size drill bit? and then he says, "OK, gimme a minute..."

Steve went over to his bin of scrap and pulled out a hunk of angle iron, into which he cut a notch. On one side of the notch, he clamped the drill bit, and on the other, a bit of rod, shimmed up so that the rod and the bit met square in the middle of the notch, and the center axis of the rod aligned with the center axis of the bit. A few tack weld later, he ran a file over the whole thing and said "ten bucks." I've used this a bunch of times and it's never failed me, although if I were to do it myself, I'd have used a brad point bit and not a standard jobber bit.

go slow.

rig up some sort of jig so the bit is held flat in the RR groove.

clear chips frequently.

. There are many ways to do the deep hole drilling choose which one is best for you :v .

. There are many ways to do the deep hole drilling choose which one is best for you :v .