Alright,I need a hand on my first rust bluing experience. I have a .54 GPR kit, my first kit and so far its been coming along great. I'm using LMF Browning and De-greaser. I started off by drawfiling and then sanding down to 220 grit. I crafted together a sweat box that seems to be working, I just boil water and put that in to increase the humidity. I'm in Wyoming so I need it. I made a PVC trough for scalding and I'm using distilled water. I'm basically following the extended LMF directions that I found at the top of the builders bench.

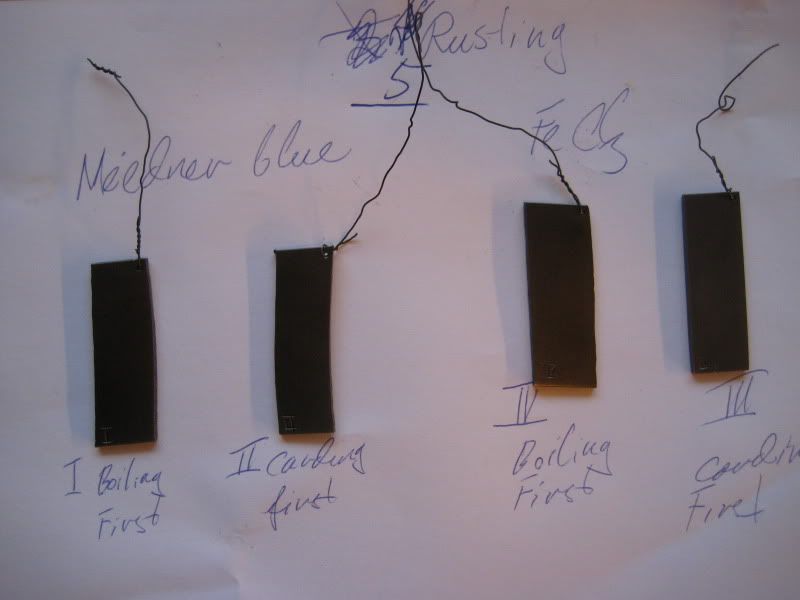

I've gone through about 4 rounds of applying the browning, scalding and carding. Everything except the barrel is done now but the barrel is the problem. I'm getting small brown/rust spots that I can't card off with 0000 steel wool, although I'm primarily using a denim rag. I'm allowing roughly 5-12 hours between carding and re-applying. Some potential issues that I see is my bath isn't working properly. I was getting leakage on one end so I tilted it up slightly on that end and rotated the barrel so each end was getting scalded about the same amount of time. As is now though, the barrel looks unevenly finished. What I'm wondering is if this is normal and I just need to keep on it or if I do have a problem with those brown spots. If I do have a problem, do I need to start over on the barrel? What do people suggest as far as improving my setup? Any advice would be greatly appreciated.

I've gone through about 4 rounds of applying the browning, scalding and carding. Everything except the barrel is done now but the barrel is the problem. I'm getting small brown/rust spots that I can't card off with 0000 steel wool, although I'm primarily using a denim rag. I'm allowing roughly 5-12 hours between carding and re-applying. Some potential issues that I see is my bath isn't working properly. I was getting leakage on one end so I tilted it up slightly on that end and rotated the barrel so each end was getting scalded about the same amount of time. As is now though, the barrel looks unevenly finished. What I'm wondering is if this is normal and I just need to keep on it or if I do have a problem with those brown spots. If I do have a problem, do I need to start over on the barrel? What do people suggest as far as improving my setup? Any advice would be greatly appreciated.