DEJ,

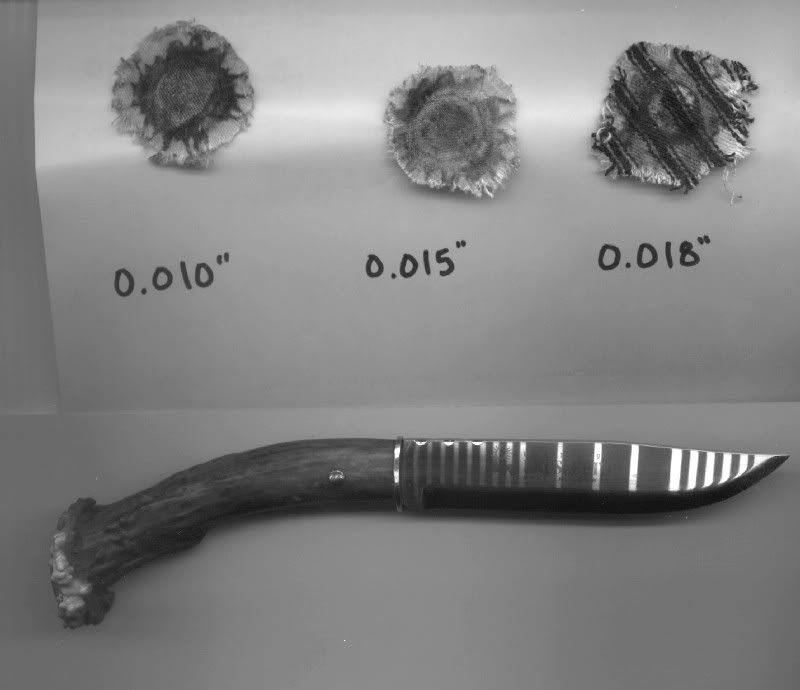

The ONLY thing that causes "burnt" holes in patching material, (assuming they are actually burnt and not cut", is the gasses getting past the patch in the rifling.

It is simply a matter of getting a tight enough patch/ball combination to make it work.

I've personally used FFFg in everything up to 20g because like some others have said, it burns cleaner. I also know guys who swear by FFg in a .32.

If the powder/patch/ball combination gives you the best accuracy you can squeeze out of your gun, use it.

However, with that being said, if you are getting burned patches, there is no way you are getting that best accuracy. Any pressure change is essentially changing the velocity of your projectile. Also, if it is burning out on one side faster than the other, can make that projectile do incredibly odd things. Both will change your point of impact and give you less consistent groups.

As someone else has said, you have to put it on paper and see what that barrel likes.

Depending on the depth of the rifling, some barrels will like a .010 undersized ball with a .010 patch, some will like a bore sized ball with .025 patch. Even barrels from the same manufacturer will vary.

I have Getz barrels on most of my guns, and they will shoot with acceptable accuracy with .005 under bore size and .018 patch. They REALLY like a bore size ball and .020 patches. Of course this makes them harder to load, but the returns are worthwhile.

I have two Getz barrels in .40 cal, both like .400 ball with .020 patching. If I am shooting gongs on a trail walk. I'll use .395 with the same .l020 patch and do very well. Both barrels are coned, and I can just thumb start the .395.

Any how, get a couple of different sized balls, and patching material, and see just what it likes.

Then go out and drive some tacks!! :m2c: :yakyak:

Sorry to be so windy.