Brasilikilt

45 Cal.

- Joined

- Dec 13, 2005

- Messages

- 560

- Reaction score

- 1

Ha....one of these days very soon, I need to post pics of knives I've actually finished, not these "in the works" photos

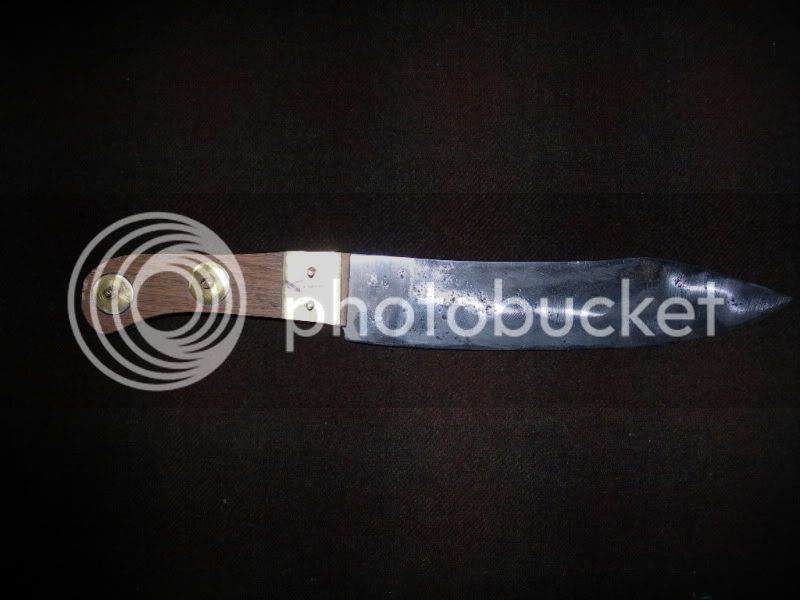

Here is my very first attempt at a HBC Camp knife, and I was hoping for some feedback from the forum.

You guys have been immensely helpful in the past with comments and criticisms by often pointing out details which I had missed

It's easier to ask now, than have something pointed out to you after it's finished

I started out with a 2 1/4" wide 1/4" thick leaf spring...during the forging the spine gained about a 16th in thickness.

The cross section of the blade was forged into a very steep wedge in preparation for draw filing it into a flat grind.

For handles, the customer requested I use a lighter colored wood, and copper instead of brass for the rivets and bolster. I figure oak or ash would be ideal for a rough-use chopper such as this.

Here it is fresh from the forge

Here it is after I ground off the forge scale, marked the blade for a little reference and cleaned up the lines a bit with a coarse file.

And here it is in hand to show that it is a bit larger than your standard HBC knife.

The future owner's wife who commissioned this blade from me, expressed her husband's love for large impressive knives, so I took the liberty to scale this one up a bit from the original dimensions.

As always, thanks for looking, hope you enjoyed checking out my first shot at this pattern.

Iain

Iain

Here is my very first attempt at a HBC Camp knife, and I was hoping for some feedback from the forum.

You guys have been immensely helpful in the past with comments and criticisms by often pointing out details which I had missed

It's easier to ask now, than have something pointed out to you after it's finished

I started out with a 2 1/4" wide 1/4" thick leaf spring...during the forging the spine gained about a 16th in thickness.

The cross section of the blade was forged into a very steep wedge in preparation for draw filing it into a flat grind.

For handles, the customer requested I use a lighter colored wood, and copper instead of brass for the rivets and bolster. I figure oak or ash would be ideal for a rough-use chopper such as this.

Here it is fresh from the forge

Here it is after I ground off the forge scale, marked the blade for a little reference and cleaned up the lines a bit with a coarse file.

And here it is in hand to show that it is a bit larger than your standard HBC knife.

The future owner's wife who commissioned this blade from me, expressed her husband's love for large impressive knives, so I took the liberty to scale this one up a bit from the original dimensions.

As always, thanks for looking, hope you enjoyed checking out my first shot at this pattern.

Iain

Iain