Travis Gregory

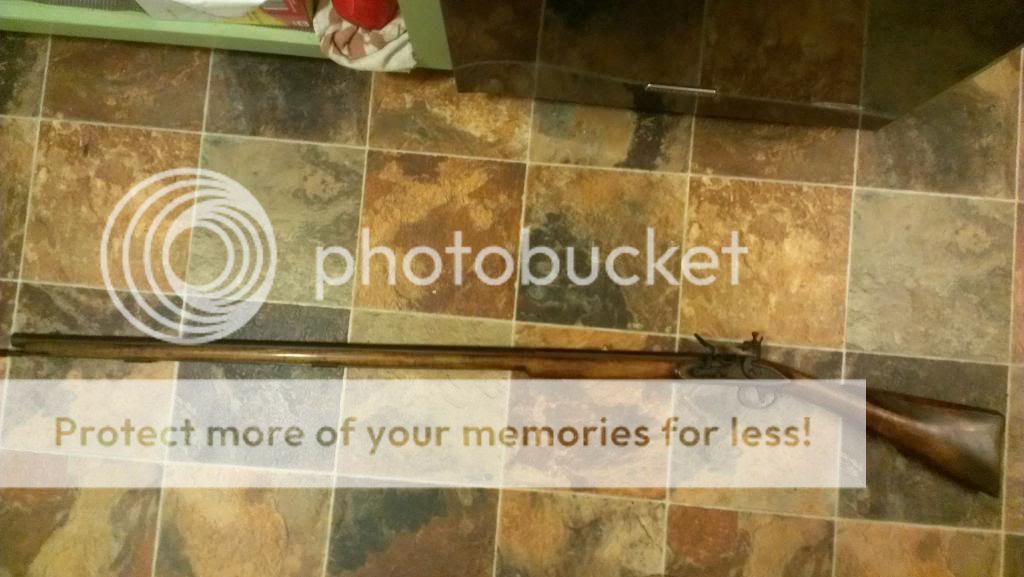

40 Cal.

- Joined

- Nov 25, 2007

- Messages

- 180

- Reaction score

- 0

If it is snug enough that you can shoot with it then do it. Then make a reference mark on the sight and barrel and remove the sight. Put a couple drops of red loc tite (#271) at the edge of the dovetail in the barrel and drive the sight back in to the reference mark. The sight will be solid in a couple hours and you wont be able to see any daylight underneath either.