Outside of using a drillpress, which I have infrequent access to, how do others keep their screw holes and barrel pin holes straight? I do own a brace and bit if necessary. Thanx Bud

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

keeping holes straight

- Thread starter bud in pa

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jdkerstetter

69 Cal.

- Joined

- Feb 15, 2012

- Messages

- 3,029

- Reaction score

- 7

I assume you are worried about pin holes coming out the opposite side on the same plane they went in at.

First, for most drilling I like to have the stock with the barrel in it in a vise. I use the barrel as a plane to set a small level on.

I'm convinced that it is often the part that you are drilling for that deflects the bit so I do it this way.

Mark both sides of the stock where you want the pin. Center punch with sharp pencil.

Drill from one side as straight and level as you can until you hit the metal part your pinning...give it just enough more to dimple the part.

Flip it around and drill as straight as you can from the other side until you hit the part again....you could drill through it at this point or take the part out to drill it through.

Just like anything else in gun building, techniques, opinions and results will vary by builder. :wink:

Hope this helps, J.D.

First, for most drilling I like to have the stock with the barrel in it in a vise. I use the barrel as a plane to set a small level on.

I'm convinced that it is often the part that you are drilling for that deflects the bit so I do it this way.

Mark both sides of the stock where you want the pin. Center punch with sharp pencil.

Drill from one side as straight and level as you can until you hit the metal part your pinning...give it just enough more to dimple the part.

Flip it around and drill as straight as you can from the other side until you hit the part again....you could drill through it at this point or take the part out to drill it through.

Just like anything else in gun building, techniques, opinions and results will vary by builder. :wink:

Hope this helps, J.D.

Guest

Tom Snyder makes drill guides for drilling with a hand drill, that make it easy to get accurate holes.

I think he gets $50 for them. His email is [email protected]

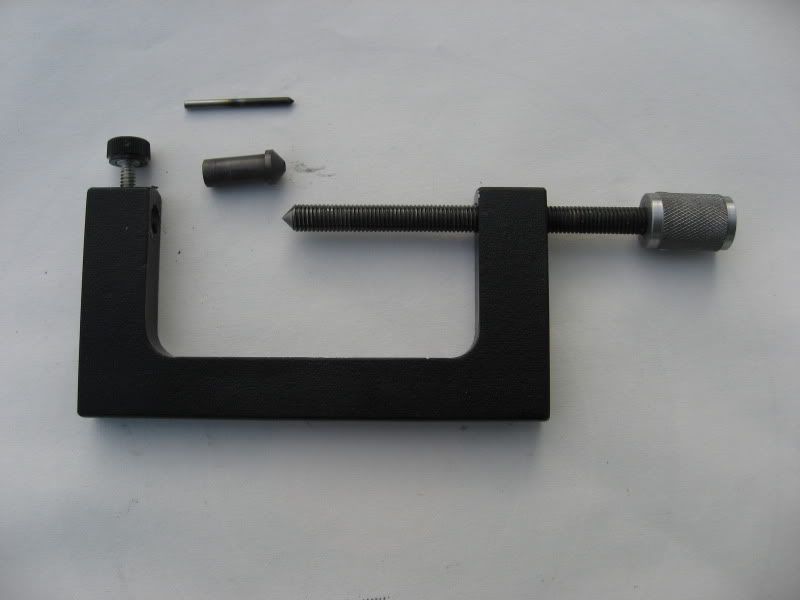

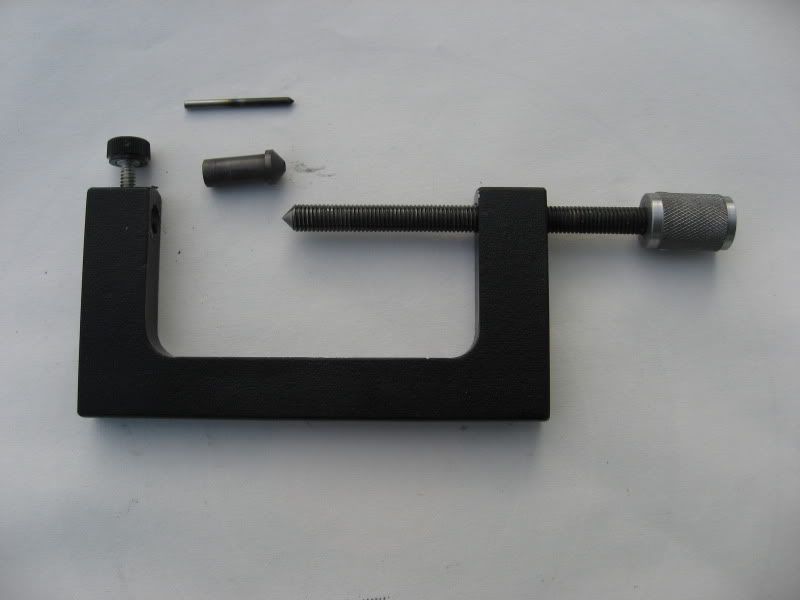

Dave Rase on another board makes one out of a c-clamp. I have one of his, and it's worth its weight in gold.

Bill

I think he gets $50 for them. His email is [email protected]

Dave Rase on another board makes one out of a c-clamp. I have one of his, and it's worth its weight in gold.

Bill

Capt. Fred

50 Cal.

- Joined

- Nov 18, 2008

- Messages

- 1,192

- Reaction score

- 0

Yup, that jig Tom makes is a great tool. It has really sped up that part of the process for me and I drill with much less mileage on the old stress-o-meter.

junkman_01

40 Cal.

- Joined

- Jan 2, 2011

- Messages

- 209

- Reaction score

- 2

J.D.,

Your method is an EXCELLENT solution even using a drill press! :thumbsup:

Your method is an EXCELLENT solution even using a drill press! :thumbsup:

jdkerstetter

69 Cal.

- Joined

- Feb 15, 2012

- Messages

- 3,029

- Reaction score

- 7

Yep. But instead of clamping the rifle in the vise I have a center point fixxed to the table that I align the off side hole on. But I follow the same procedure....half way through and flip her over to do the other side....to avoid those skinny drill bits wandering.

J.D.

J.D.

One might take two pieces of wood 12" long and scribe a line dead center on one side then mark off equal distant holes one each scribe line then put then together and clamp with a piece of metal in the middle, then drill thru both sides to the metal. When finished put the pieces of wood in the drawer and you will have a large supply of straight pre-drilled holes whenever you have a need for them :idunno:

Similar threads

- Replies

- 8

- Views

- 466

- Replies

- 35

- Views

- 4K

- Replies

- 28

- Views

- 2K