- Joined

- Mar 7, 2007

- Messages

- 686

- Reaction score

- 2,095

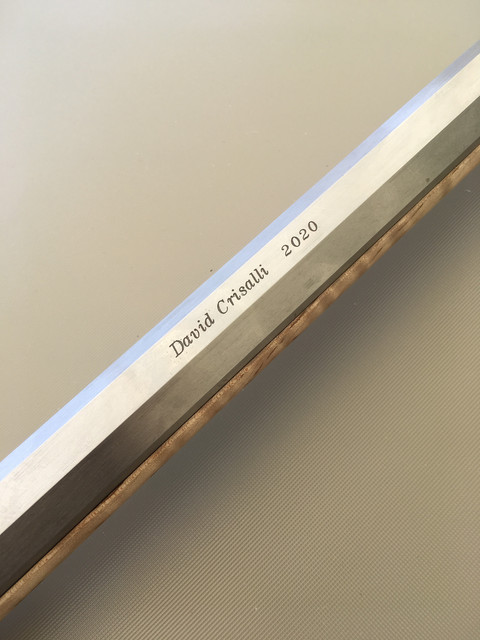

I wanted to try out one of Jim Kibler's new kits last year. The kit sat around for a fair amount of time before I started in. It has been done for several months now but here are the posts I was intending to put up as I went along. Even thought these posts are late, I thought that others here might appreciate the information about one of Jim's excellent kits and what you can do with it......

*********************************************************************************************************************************************************************************

I decided that I wanted to do a little carving on the stock. As is usually the case, it is not the carving that takes time, it is trying to decide on what to carve. So rather than doing anything overly original, I thought I would just use a carving theme from one of Jim's rifles.....after all, the kit is from Jim.....

So I picked a design I liked a lot when I first saw it and I knew it was going to be a tough one to try to mimic....AND IT WAS !!!! None of these are completely finished yet but I wanted to get the overall design cut. I will finish smoothing the backgrounds and cleaning up some details when I actually get around to finishing the rifle.....

I started off by putting a molding along the ram rod channel and then thinned out the wrist some side to side and top to bottom. Did the usual lock molding, etc., but here is the major stuff.....

Butt stock main carving layout:

First Cuts:

Mostly done......

I wanted to change the carving around the rear pipe so, instead of using the original design, I made up a variation on the theme Jim used elsewhere on his rifle......layout of the design.......

And cut......

Breach carving.........

Toughest one of all......patchbox !

*********************************************************************************************************************************************************************************

I decided that I wanted to do a little carving on the stock. As is usually the case, it is not the carving that takes time, it is trying to decide on what to carve. So rather than doing anything overly original, I thought I would just use a carving theme from one of Jim's rifles.....after all, the kit is from Jim.....

So I picked a design I liked a lot when I first saw it and I knew it was going to be a tough one to try to mimic....AND IT WAS !!!! None of these are completely finished yet but I wanted to get the overall design cut. I will finish smoothing the backgrounds and cleaning up some details when I actually get around to finishing the rifle.....

I started off by putting a molding along the ram rod channel and then thinned out the wrist some side to side and top to bottom. Did the usual lock molding, etc., but here is the major stuff.....

Butt stock main carving layout:

First Cuts:

Mostly done......

I wanted to change the carving around the rear pipe so, instead of using the original design, I made up a variation on the theme Jim used elsewhere on his rifle......layout of the design.......

And cut......

Breach carving.........

Toughest one of all......patchbox !

Last edited: