ricktwin said:Here's a horn I got at the DayLilly Wine Festival this summer. Here is the horn's process so far. Thanks for looking.

Ron

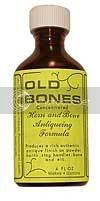

To continue along, here is the horn I'm making with the spout completed and the base plug in place. I wanted to try the oversized base plug instead of the exact fit type. I've decided not to do engrailing at the throat separation, but instead, put some nice scimmed banners at the divide. I'll keep you all posted as the progress goes along. Now I have to decide what pattern I want on it. I'll "antique" it when I get the scrimming done, along with a simple leather strap.

Ron