kruzer1

40 Cal.

- Joined

- Aug 15, 2010

- Messages

- 201

- Reaction score

- 42

OK follow up question.

Thanks everyone for letting me know some sources for smoothbore blanks.

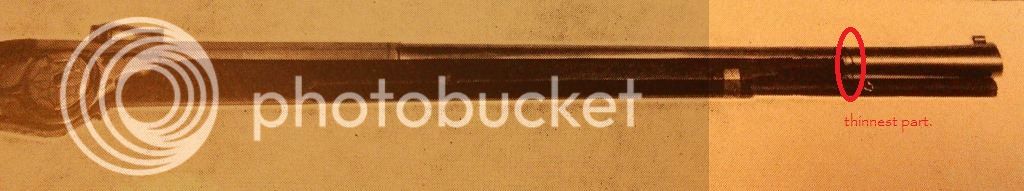

I am going to get a straight octagon and lathe this 16th century spanish barrel:

My friend owns the lathe and guide's me in using it. My question is for this profile I will have to take a lot of metal out in the center. I am thinking of getting a 1" tube in either .54, .58, or .62.

Generally the bigger the caliber the better for my project, but I want to make sure I have enough to make it look decent and keep it safe

Thanks everyone for letting me know some sources for smoothbore blanks.

I am going to get a straight octagon and lathe this 16th century spanish barrel:

My friend owns the lathe and guide's me in using it. My question is for this profile I will have to take a lot of metal out in the center. I am thinking of getting a 1" tube in either .54, .58, or .62.

Generally the bigger the caliber the better for my project, but I want to make sure I have enough to make it look decent and keep it safe