These are my go to hunting knives. View attachment 100492

Just used them again

View attachment 106168

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let’s see them hunting knives

- Thread starter Stykbow

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I’ve used this one processing deer… But I prefer a smaller knife for gutting and dressing deer and other game.

Usually it’s the Buck Ranger folder I’ve had in my pocket for over 35 years… Well I am on the second one.. but still have the first!

Thats rather interesting. I have a chipped cut throat razor somewhere that I've been wondering what to do with...Not a hunting knife but very capable patch knife.View attachment 106113View attachment 106114

My grandfather made this from the blade of a silage chopper somewhere in the 1930's-40's. Blade is 5 1/4". The handle is heavy leather lacing wound and then capped with a washer soldered in place. Bottom sheath is the original he made. As it deteriorated I wanted to leave it as is but no way did I trust it on my belt - so I carried it sheathed in my pack. A friend made the replacement sheath at my request.

I was 16 (a long time ago) when my Grandpa gave it to me - and then took it back five minutes later saying he'd changed his mind and that I had to buy it. In shock I asked how much, he then smiled and said 'ten cents'. He then related the old story that if you gifted someone a knife you could end up getting cut by it.

This knife has cut every deer I ever shot, plus an Alaskan caribou and a Colorado elk. Good chance it'll be with me in my pine box.

View attachment 102342

I’m currently refinishing the handle on a knife that my grandfather made and the blade is remarkably similar in size and shape to this one! It had to be over 50 years old at least. Might have been used for killing hogs.

BillKilgore

50 cal.

- Joined

- Dec 5, 2021

- Messages

- 355

- Reaction score

- 595

I made this knife a few years ago. I have not hunted in many years, but I think it would be a good one.

I see an old Puma "White Hunter" there in the middle. That brings back memories.Here are a few old friends. I don't have anything that I have actually used on game that is period correct "Yet". I have the 7" belt knife and "Hawk" is building me an English Scalper Blade that I will be putting together here next month. Maybe next year I will get to put those two to use.

View attachment 106210

View attachment 106211

Wish I had never sold mine?

God bless:

Two Feathers

^ Yessir,

They don’t make’m quite like that anymore. I know that the back edge is capable of some pretty tough work and I have put it through its paces. Now days however, I take it easy on it and use something else. Just not worth buggering it up.

RM

They don’t make’m quite like that anymore. I know that the back edge is capable of some pretty tough work and I have put it through its paces. Now days however, I take it easy on it and use something else. Just not worth buggering it up.

RM

Rod Man:

Yup...if you can even find one of those, you're looking at $300.00. They're a collectable, treat it nice:~))))

Merry Christmas.

God bless:

Two Feathers

Yup...if you can even find one of those, you're looking at $300.00. They're a collectable, treat it nice:~))))

Merry Christmas.

God bless:

Two Feathers

Rod Man:

Yup...if you can even find one of those, you're looking at $300.00. They're a collectable, treat it nice:~))))

Merry Christmas.

God bless:

Two Feathers

And to you Sir!

- Joined

- Mar 7, 2007

- Messages

- 686

- Reaction score

- 2,095

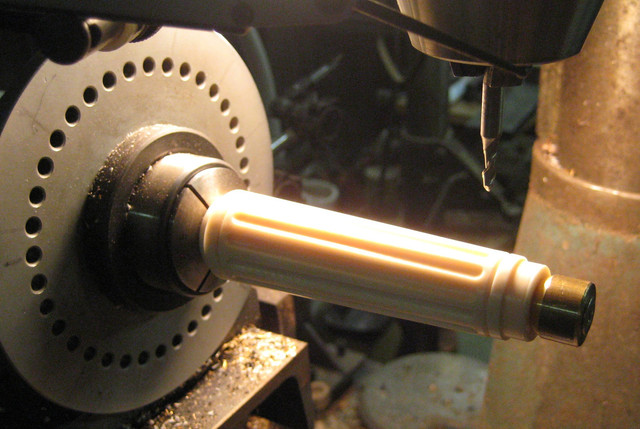

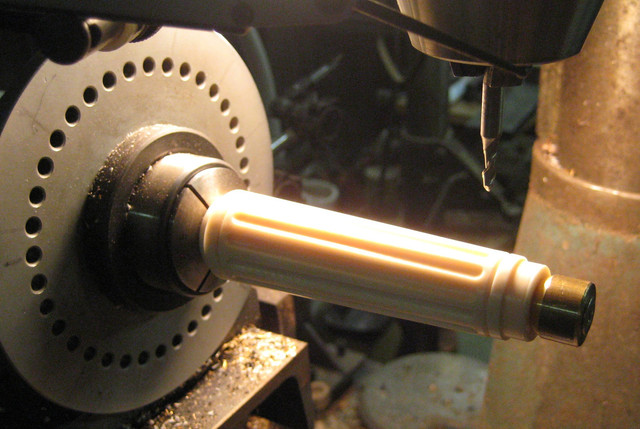

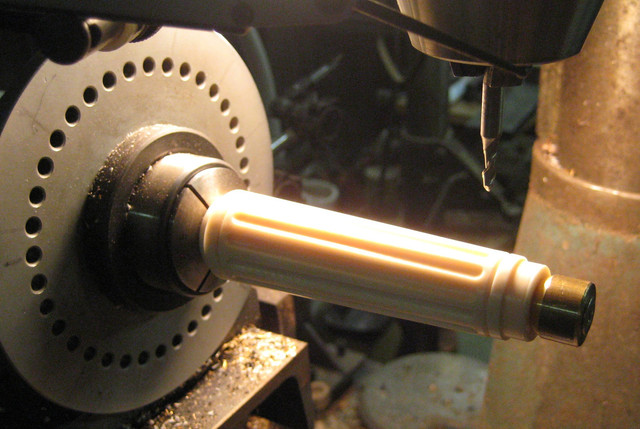

Well, after my last attempt at knife making went a little overboard, I thought I would make one a lot simpler...saw a blade blank out of O-1 steel, put on a simple brass cross guard, a wood handle, and rivet on an end cap. Just a simple project to do between the demands of work.....

The whole idea went to $#*! in a hand cart right from the start. First, I had no idea what sort of trouble I was getting into by thinking I could properly heat treat O-1 with the very limited equipment I have for that type of work. I only found out after I asked Wick Ellerbe for some advice and after I had invested way more time that I planned in shaping (incorrectly I might add) the blade. Wick took pity on me and VERY generously offered to bail me out and do the heat treating for me. (Wick also offered a lot of his time and advice on blade shaping, file guides, types of steel to use and a myriad of other knife making tips. I very much appreciate his help.)

While the blade was off to Wick for heat treat, I went to work on the grip. But, as they say about the best laid plans of mice and men, things seemed to take on a life of their own. I did manage to make a simple straight, flat brass guard, but ended up embellishing the edge a bit with some boarder engraving...not too bad though, I thought. Simple...elegant...not over done...Then I went looking for a suitable piece of hardwood to make the grip but stumbled, almost immediately, upon a piece of Hippopotamus ivory I had. Before I could control myself, I had already cut up the Hippo ivory and turned the grip. And then it looked too plain, so I added the flutes (full length this time, Smart Dog). The simple ferrules looked too plain now, with the fluted ivory and all, so I had to add some wedding band type decoration.

Anyway, you can see what happened.

At any rate, the blade is 10 inches long, the grip is stained with tea, and this time I went for broke and riveted the butt cap on.

The whole idea went to $#*! in a hand cart right from the start. First, I had no idea what sort of trouble I was getting into by thinking I could properly heat treat O-1 with the very limited equipment I have for that type of work. I only found out after I asked Wick Ellerbe for some advice and after I had invested way more time that I planned in shaping (incorrectly I might add) the blade. Wick took pity on me and VERY generously offered to bail me out and do the heat treating for me. (Wick also offered a lot of his time and advice on blade shaping, file guides, types of steel to use and a myriad of other knife making tips. I very much appreciate his help.)

While the blade was off to Wick for heat treat, I went to work on the grip. But, as they say about the best laid plans of mice and men, things seemed to take on a life of their own. I did manage to make a simple straight, flat brass guard, but ended up embellishing the edge a bit with some boarder engraving...not too bad though, I thought. Simple...elegant...not over done...Then I went looking for a suitable piece of hardwood to make the grip but stumbled, almost immediately, upon a piece of Hippopotamus ivory I had. Before I could control myself, I had already cut up the Hippo ivory and turned the grip. And then it looked too plain, so I added the flutes (full length this time, Smart Dog). The simple ferrules looked too plain now, with the fluted ivory and all, so I had to add some wedding band type decoration.

Anyway, you can see what happened.

At any rate, the blade is 10 inches long, the grip is stained with tea, and this time I went for broke and riveted the butt cap on.

- Joined

- Mar 7, 2007

- Messages

- 686

- Reaction score

- 2,095

retrieverman

32 Cal

I have quite a few hunting knives, but this is one of my favorites. It was made by Rick Menefee in Oklahoma.

Stykbow

50 Cal.

- Joined

- Aug 2, 2021

- Messages

- 1,049

- Reaction score

- 2,470

Well, after my last attempt at knife making went a little overboard, I thought I would make one a lot simpler...saw a blade blank out of O-1 steel, put on a simple brass cross guard, a wood handle, and rivet on an end cap. Just a simple project to do between the demands of work.....

The whole idea went to $#*! in a hand cart right from the start. First, I had no idea what sort of trouble I was getting into by thinking I could properly heat treat O-1 with the very limited equipment I have for that type of work. I only found out after I asked Wick Ellerbe for some advice and after I had invested way more time that I planned in shaping (incorrectly I might add) the blade. Wick took pity on me and VERY generously offered to bail me out and do the heat treating for me. (Wick also offered a lot of his time and advice on blade shaping, file guides, types of steel to use and a myriad of other knife making tips. I very much appreciate his help.)

While the blade was off to Wick for heat treat, I went to work on the grip. But, as they say about the best laid plans of mice and men, things seemed to take on a life of their own. I did manage to make a simple straight, flat brass guard, but ended up embellishing the edge a bit with some boarder engraving...not too bad though, I thought. Simple...elegant...not over done...Then I went looking for a suitable piece of hardwood to make the grip but stumbled, almost immediately, upon a piece of Hippopotamus ivory I had. Before I could control myself, I had already cut up the Hippo ivory and turned the grip. And then it looked too plain, so I added the flutes (full length this time, Smart Dog). The simple ferrules looked too plain now, with the fluted ivory and all, so I had to add some wedding band type decoration.

Anyway, you can see what happened.

At any rate, the blade is 10 inches long, the grip is stained with tea, and this time I went for broke and riveted the butt cap on.

- Joined

- Aug 15, 2014

- Messages

- 238

- Reaction score

- 587

Some of the blade I have made over the years

Most of these were done a good 15-20 yrs ago

Most of these were done a good 15-20 yrs ago

Ragged Edge

36 Cl.

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 12

- Views

- 985

- Replies

- 23

- Views

- 902