flintbuilder

32 Cal.

- Joined

- Dec 6, 2010

- Messages

- 28

- Reaction score

- 0

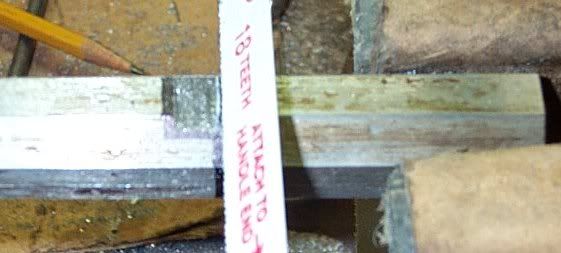

I have never cut a dovetail before so I had someone show me with a hack saw and straight triangular file. I did one with help but now I am on my own to cut the rest on two barrels? Does anyone have some words of advice or skill they would like to pass along?

The lug just fit into the one I cut and as I started to file it flush with the barrel flat it came loose and it slides in and out now. How can I get it to fit tight again without putting big dents in the barrel by using a center punch, or is that the only way? :hatsoff:

The lug just fit into the one I cut and as I started to file it flush with the barrel flat it came loose and it slides in and out now. How can I get it to fit tight again without putting big dents in the barrel by using a center punch, or is that the only way? :hatsoff: