-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lyman GPR flint kit finish

- Thread starter JeffDavis

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I used the Laurel Mtn browning and rubbed it back semi-bright with steel wool.

Applied a few stains to the wood but ended up working most of it out when I wet sanded with tung oil to fill the pores in the grain. So I have a "few" coats of tung oil on it only...

Applied a few stains to the wood but ended up working most of it out when I wet sanded with tung oil to fill the pores in the grain. So I have a "few" coats of tung oil on it only...

- Joined

- Jan 3, 2004

- Messages

- 14,767

- Reaction score

- 319

Tung oil finish here, too. I learned the wonders of linseed oil and its various concoctions over 40 years ago from the gunsmith I worked for in my teens. Have used it lots and know its ins and outs. But it took me 40 years to finally get smart and try tung oil finish. Dang! It's tougher and much more weather resistant than linseed or variations.

I brush on as much as will soak into the stock reasonably for the first coat and wipe off the excess. Let it dry thoroughly, like 48 hours in a warm place. If you want to "wet" sand it while the tung is still wet this first time around, that will help fill the pores.

When it's ABSOLUTELY dry and hard, then start putting on very thin coats. Just put a drop on your finger and spread it as far as it will go--- till your hand starts dragging. Do that over the whole stock and let it dry 24 hours in the warm place before adding another coat. If you try to rush it and add a second before the first is thoroughly dry and hard, it can take forever to dry.

It usually takes 6-8 of those thin coats to get the finish I want. More if I didn't do a good job of filling. End results are a really hard, weatherproof finish.

Don't forget a coat of finish on all all inner surfaces too. That will help weatherproof it and keep it from soaking up water and swelling on rainy days.

I brush on as much as will soak into the stock reasonably for the first coat and wipe off the excess. Let it dry thoroughly, like 48 hours in a warm place. If you want to "wet" sand it while the tung is still wet this first time around, that will help fill the pores.

When it's ABSOLUTELY dry and hard, then start putting on very thin coats. Just put a drop on your finger and spread it as far as it will go--- till your hand starts dragging. Do that over the whole stock and let it dry 24 hours in the warm place before adding another coat. If you try to rush it and add a second before the first is thoroughly dry and hard, it can take forever to dry.

It usually takes 6-8 of those thin coats to get the finish I want. More if I didn't do a good job of filling. End results are a really hard, weatherproof finish.

Don't forget a coat of finish on all all inner surfaces too. That will help weatherproof it and keep it from soaking up water and swelling on rainy days.

forconXXXXX

32 Cal.

- Joined

- Dec 25, 2005

- Messages

- 8

- Reaction score

- 0

I browned the barrel on my gpr with Laurel Mountain forge solution.I am VERY happy with the way it turned out.I think it gives the gun a very authentic look and it really stands up to the elements well.It took a while for me to get a nice even finish but it was definitly worth the effort.

The time honored formula I was given is, after all metal parts are removed

tung oil is applied liberally but hand rubbed until dry.

put the gun away somewhere warm.

repeat once daily for a week, once weekly for a month, once monthy for a year. Annually thereafter.

This came from the Chinese - what the hell do they know about tung?

tung oil is applied liberally but hand rubbed until dry.

put the gun away somewhere warm.

repeat once daily for a week, once weekly for a month, once monthy for a year. Annually thereafter.

This came from the Chinese - what the hell do they know about tung?

Use Permalyn or Tru-Oil on it first to seal the wood from moisture. Tung Oil is not waterproof, Permalyn or Tru-Oil is. Put it on wet, let it soak & wipe off the excess. Let it sit for 12-25 hrs & 0000 steel wool it & then put the Tung Oil to it.

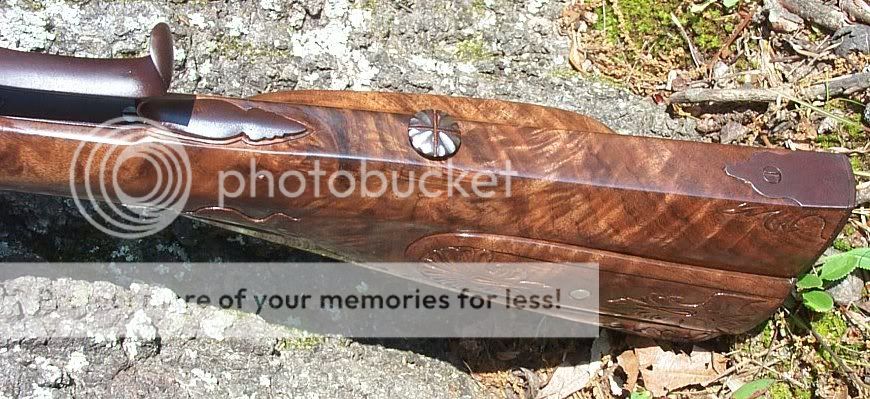

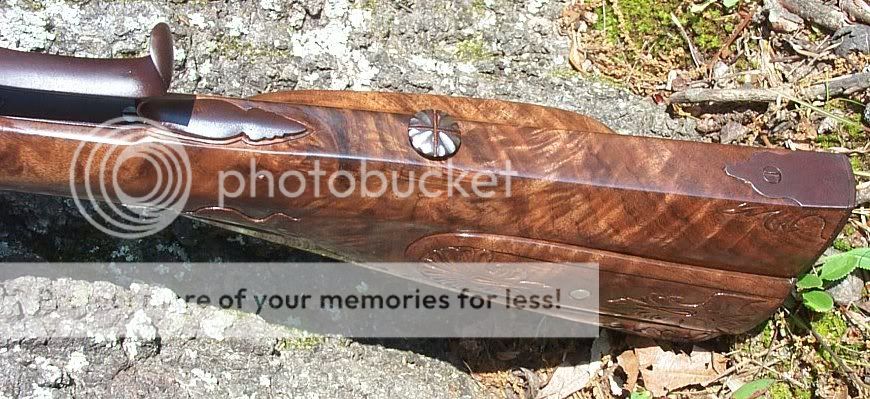

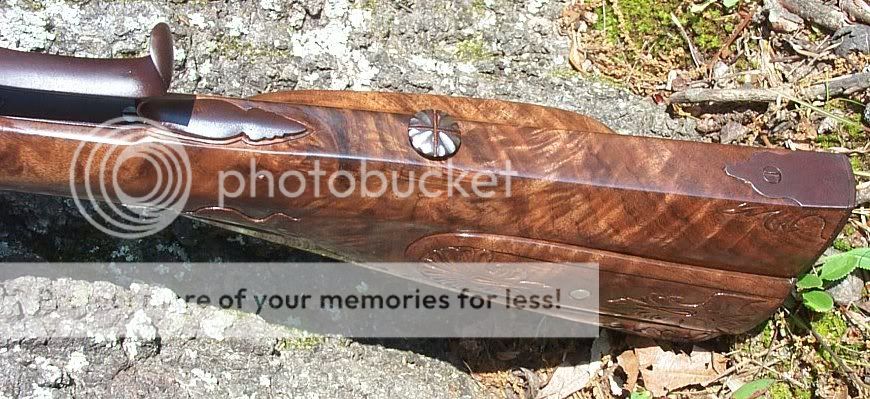

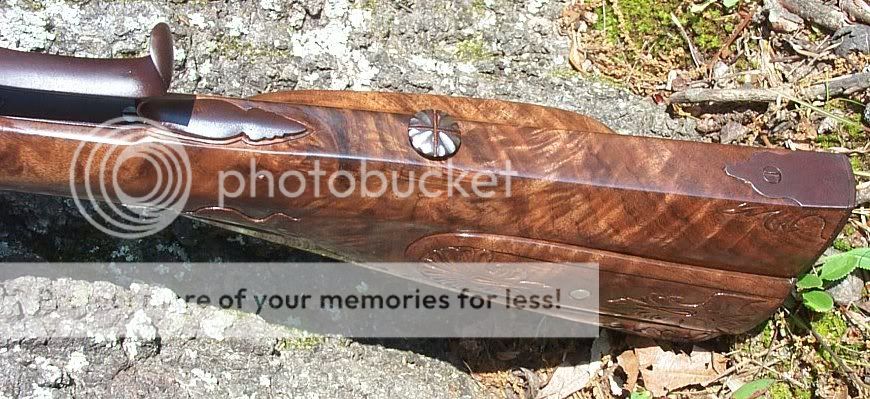

This is a Tung Oil finish on this Jaeger rifle I built some years ago.

This is a Tung Oil finish on this Jaeger rifle I built some years ago.

- Joined

- Jun 12, 2005

- Messages

- 7,995

- Reaction score

- 1,003

wow, Birddog, that's a really sharp looking rifle!

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

Keith: Nice gun. I like your system of closing the pores with either Tru-oil, or Permalyn( altho I don't like Permalyn much), and then following it up with fine coats of Tung Oil I have worked with both Tung Oil and Tru-oil, but not together. I am going to try this on the next stock I do.

Thanks for sharing the tip.

Paul

Thanks for sharing the tip.

Paul

longcruise

70 Cal.

One thing I would avoid is staining of the GPR walnut stock. It comes up very nicely with oil alone. Staining it seems to muddy the grain.

If you cut Shellac about 1 to 2 parts shellac and denatured alcohol and use it as a filler you will save much headaches with unfilled grain. You can use plain old Zinser (Bullseye). Work the cut shellac into the wood with a piece of 320 sandpaper in a circular motion. Put it on heavily. When it is dry, do it again without taking the first coat down at all. Then, when it is thorougly dry, take it all down with 320 till there is no shellac left on the surface of the wood, but only in the pores. That way when you apply the oil it won't take many coats to fill the grain.

Maple does not present this grain filling problem as walnut does.

The last GPR I built for a friend had nice looking wood but, intererstingly, when sanded it produced a whitish substance from the grain. It wipe away easily. Made me think that it had been stabilized as the knife makers sometimes do with their scales.

If you cut Shellac about 1 to 2 parts shellac and denatured alcohol and use it as a filler you will save much headaches with unfilled grain. You can use plain old Zinser (Bullseye). Work the cut shellac into the wood with a piece of 320 sandpaper in a circular motion. Put it on heavily. When it is dry, do it again without taking the first coat down at all. Then, when it is thorougly dry, take it all down with 320 till there is no shellac left on the surface of the wood, but only in the pores. That way when you apply the oil it won't take many coats to fill the grain.

Maple does not present this grain filling problem as walnut does.

The last GPR I built for a friend had nice looking wood but, intererstingly, when sanded it produced a whitish substance from the grain. It wipe away easily. Made me think that it had been stabilized as the knife makers sometimes do with their scales.

LMF browning is the only one I use....nicely etched matte finish, beautiful color, holds up well and easy to use as well. All my stocks get 2- 3 saturation coats of LMF Sealer w/ a complete wipe off after every coat. After the last coat, a good drying and then a rub down w/ 0000 steel wool. Then 2-3 very thin hand rubbed coats of Wahkon Bay Trucoat. The resultant finish lacks any sheen but if some shine is desired, a good rubbing w/ a fluffy towel will yield a satin finish.After staining and prior to applying the sealer, I rub the stock briskly w/ 0000 steel wool to remove unabsorbed surface stain residue that causes "cloudiness" and to lighten up high wear areas.....Fred

Boy, Birddog

Talk about a waste!

Someone sure went to a lot of work to do all that carving only to have his work upstaged by that wood! :rotf:

Oh, nice job of carving. :thumbsup:

:grin:

Talk about a waste!

Someone sure went to a lot of work to do all that carving only to have his work upstaged by that wood! :rotf:

Oh, nice job of carving. :thumbsup:

:grin:

Ya that's some pretty wild grain on that butt,,Is that the one Del got? Nice piece, nice salvage on the patch box lid too, really adds to it.

I've been putsin on a pecatonica t/c rpl in m3 for awhile now, and I've already got the permalyn for the first coat as described,,then tung.

I've watched birdgog say the same thing for years now,,it's just gotta be one of the right way's to do it! :bow:

I've been putsin on a pecatonica t/c rpl in m3 for awhile now, and I've already got the permalyn for the first coat as described,,then tung.

I've watched birdgog say the same thing for years now,,it's just gotta be one of the right way's to do it! :bow:

But anyway, the rifle was one I had always wished I had kept so I am glad to have it back.

I don't remember how many hand rubbed coats of Tung Oil is on that rifle, but for some reason 18 or 20 sticks in my head. I put allot of time in that rifle on the finish alone. I can build a rifle in the white in the time I have in that finish, as it is like a piece of glass.

Keith

Zonie said:Boy, Birddog

Talk about a waste!

Someone sure went to a lot of work to do all that carving only to have his work upstaged by that wood! :rotf:

Oh, nice job of carving. :thumbsup:

:grin:

Yes... :redface: Very humbling when the wood is nicer than the carving..... :haha:

That jäger is a beautiful rifle and have been thinking of building one {hopefully, but not likely, as nice as yours} but have 2 problems w/ doing so. First off the precarves on the market are, from what I've been told, not styled correctly and doing one from scratch kinda stretches my design ability seeing I've got slim Bucks County LRs constantly on the mind. I really admire builders who can "change hats" at will and produce a wide variety of MLer styles. Again...a very professional job....Fred

fort fireman

45 Cal.

- Joined

- Jul 6, 2008

- Messages

- 715

- Reaction score

- 2

I've heard that tru-oil is basically tung oil with some driers in it. Is this true?

I really don't know. I am not a PC builder so it really makes no dif to me> All I know is it works. Has to be more than just driers tho, as Tru-Oil is waterproof & Tung Oil is not. :hmm:

But we are talking 6 bucks to finish 2-3 finish rifles, so to me that is well worth it to seal up the rifles.

:thumbsup:

But we are talking 6 bucks to finish 2-3 finish rifles, so to me that is well worth it to seal up the rifles.

:thumbsup:

First off the precarves on the market are, from what I've been told.

That doesn't bother me a bit, whether they are PC, HC, whatever. All I am concerned is whether I like them. If I do I build them & if I don't then I don't. I learned long ago no matter what you build, some will like them , some won't. Ya can't please everyone, so I am going to concentrate on pleasing me. :thumbsup: And thank you for the complements the rifle. :wink:

Birddog6 said:Has to be more than just driers tho, as Tru-Oil is waterproof & Tung Oil is not. :hmm:

:thumbsup:

I have lot's of respect for you BD and I let it go the 1st time, but not twice.

In his book titled The Wood Finisher, Bruce Johnson rates Tung oil as very good in it's water resistance (vs, good for boiled linseed oil). What's better? Lacquer & varnish, that all!

Finnwolf

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

There are all kinds of varnishes. Marine spar varnish is among the best at sealing out water, and resisting Ultra violet light. But, each brand tends to decide what kind and how fast the driers are that they may place( or not ) in their varnish.

Shellac is another pore filling finish. Lacquer is good, but generally is not as durable. Shellac does not tolerate UV light well. If its used as a filler, then cover it with several layers of varnish or oil.

Shellac is another pore filling finish. Lacquer is good, but generally is not as durable. Shellac does not tolerate UV light well. If its used as a filler, then cover it with several layers of varnish or oil.