azsixshooter

36 Cl.

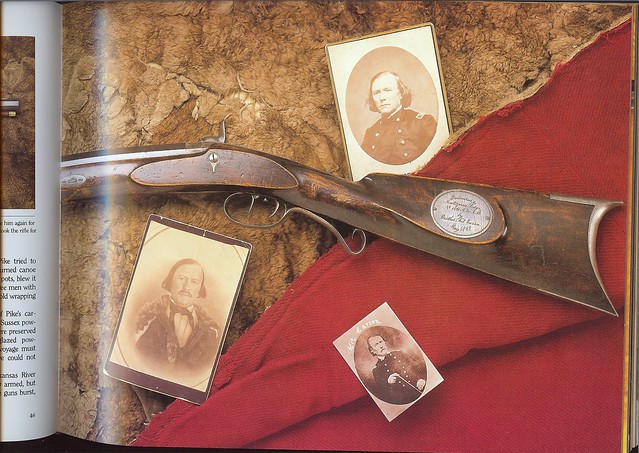

I've been working on this build for over a year, although I never seem to get enough time to really sit and get a lot done at once. I had hoped to get all the sanding done over the last 2 days but my plans didn't work out and I barely sat down to start working on it late last night and there wasn't enough good light so I didn't get much done. I think it's getting pretty close to being ready to start finish sanding after I blend the wood/metal areas and thin the wood out slightly in a few places.

I thought I would post some pics and see if anyone has any thoughts or advise for me at this point. I'm pretty happy with the way it's coming along so far. There were a couple times when I cut too deep or too far but I think I managed to recover as well as possible.

I hope everyone had a happy Independence Day. I fired off this GPR twice last night for my neighbors to see and they got a kick out of that.

Thanks for any opinions,

Steve

I thought I would post some pics and see if anyone has any thoughts or advise for me at this point. I'm pretty happy with the way it's coming along so far. There were a couple times when I cut too deep or too far but I think I managed to recover as well as possible.

I hope everyone had a happy Independence Day. I fired off this GPR twice last night for my neighbors to see and they got a kick out of that.

Thanks for any opinions,

Steve

all 197

all 197