To be HC, a Bucks County LR should have a correctly styled entry pipe and I think many are hesitant to tackle one of these slim, beautiful LRs because the entry pipe has to be made...not available from any suppliers. Here's my way of making a 2 piece BC entry pipe. By the way, I'm presently making this entry pipe for my last LR....Fred

First shown are the male and female forming blocks made from oak. The male block simulates the forestock cross section and the female block is the same cross section plus the .040 brass thickness. As shown, these blocks will make a one or two piece BC entry pipe. The two piece is shown and I think it's the easier of the two to make.

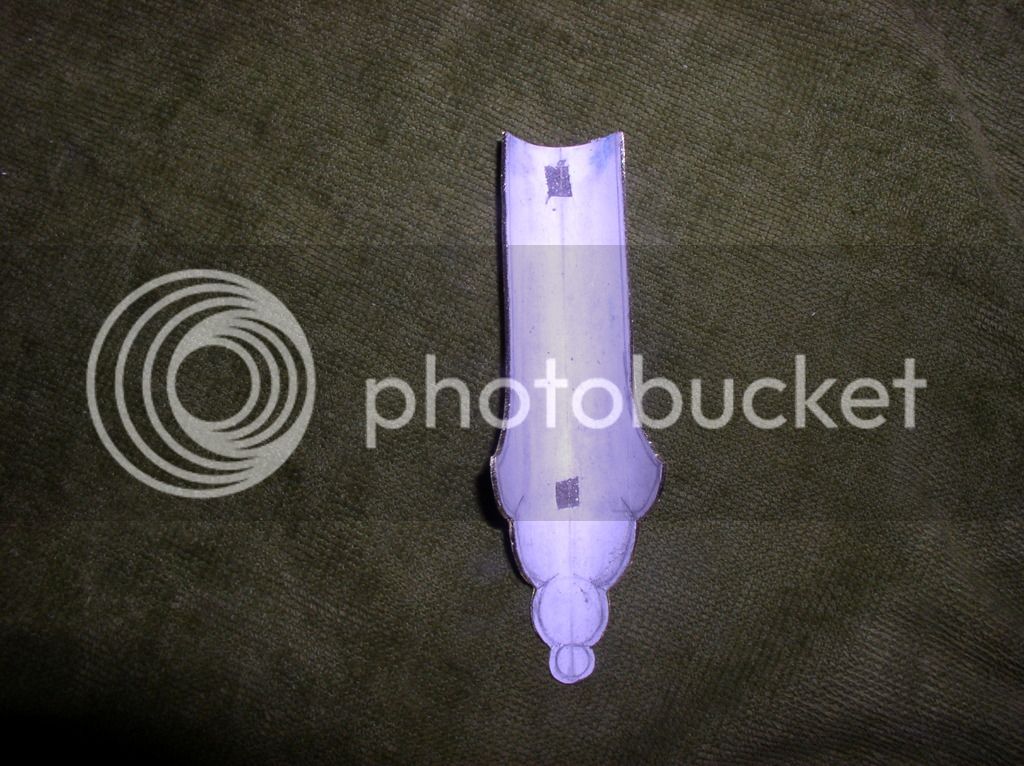

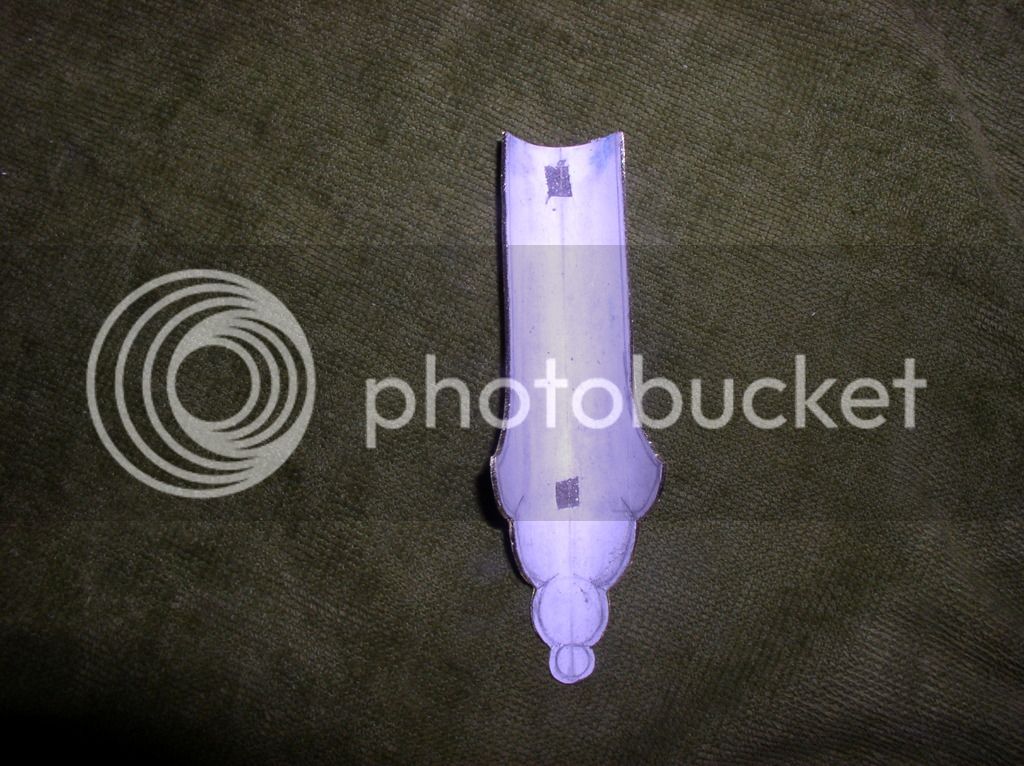

This pic shows the formed finial...the layout is on the inside surface of the pipe.

The male block w/ the finial.

A drill the same size as the RR pipe is used to peen the radius and dia that goes around the RR pipe.

This is just the finial....the cutouts are used to align the paper layout w/ the centerline on the brass sheet.

This is the RR pipe and the tab for pinning favors the finial and one pin is used.

The layout is on the paper and after the finial is filed to it, it is removed and the finial end towards the RR pipe holder is peened into a spherical shape and the dia that fits around the RR pipe is also peened. A couple of anneals w/ a torch is necessary to prevent tearing of the brass.

Pictured below is a top view of a 2 piece BC entry pipe showing the radiused transition to the RR pipe itself....the two pieces are joined w/ silver solder....Fred

First shown are the male and female forming blocks made from oak. The male block simulates the forestock cross section and the female block is the same cross section plus the .040 brass thickness. As shown, these blocks will make a one or two piece BC entry pipe. The two piece is shown and I think it's the easier of the two to make.

This pic shows the formed finial...the layout is on the inside surface of the pipe.

The male block w/ the finial.

A drill the same size as the RR pipe is used to peen the radius and dia that goes around the RR pipe.

This is just the finial....the cutouts are used to align the paper layout w/ the centerline on the brass sheet.

This is the RR pipe and the tab for pinning favors the finial and one pin is used.

The layout is on the paper and after the finial is filed to it, it is removed and the finial end towards the RR pipe holder is peened into a spherical shape and the dia that fits around the RR pipe is also peened. A couple of anneals w/ a torch is necessary to prevent tearing of the brass.

Pictured below is a top view of a 2 piece BC entry pipe showing the radiused transition to the RR pipe itself....the two pieces are joined w/ silver solder....Fred