- Joined

- Mar 7, 2007

- Messages

- 702

- Reaction score

- 2,184

I did some modifications to a Chambers Late Ketland for a half stock rifle I have in the works. Thought I would show you what I did to modify the look the lock.

First, the "hook" at the top of the existing **** turns backward. Just personal preference, but I like the look of the "hook" turning forward. Harder to do, but it looks more graceful to me. Here is how the **** came on the lock:

I TIG welded a blob of steel on the top of the ****. Here is how it looked before filing.....the look I was going for is shown at the right on another **** I made many years ago:

After a little grinding and filing, it came out like this:

I like the look of a more "waterproof" pan, so I decided to modify that as well. Here is the pan the way the lock comes....

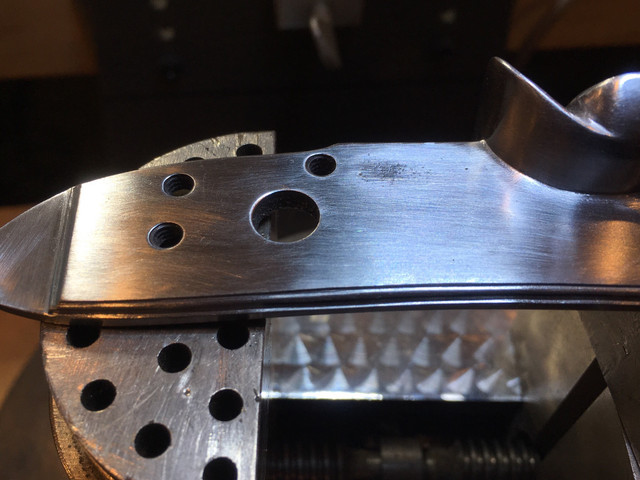

After some filing and polishing, it looks like this.....

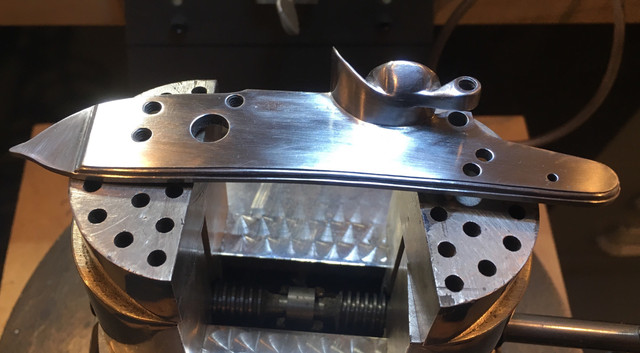

I don't have all the parts done yet, but this photo shows the plate with the modified pan and the **** with the altered curl at the top......

First, the "hook" at the top of the existing **** turns backward. Just personal preference, but I like the look of the "hook" turning forward. Harder to do, but it looks more graceful to me. Here is how the **** came on the lock:

I TIG welded a blob of steel on the top of the ****. Here is how it looked before filing.....the look I was going for is shown at the right on another **** I made many years ago:

After a little grinding and filing, it came out like this:

I like the look of a more "waterproof" pan, so I decided to modify that as well. Here is the pan the way the lock comes....

After some filing and polishing, it looks like this.....

I don't have all the parts done yet, but this photo shows the plate with the modified pan and the **** with the altered curl at the top......