coehornboy

40 Cal.

- Joined

- Mar 24, 2005

- Messages

- 218

- Reaction score

- 1

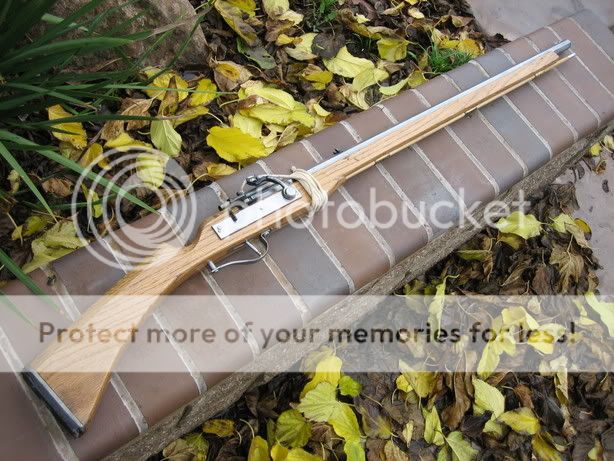

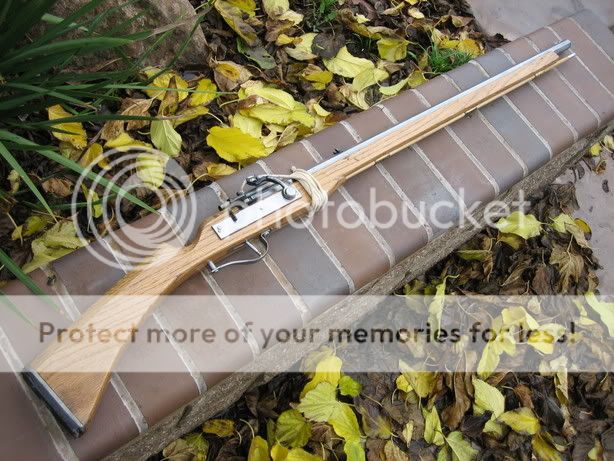

Here is my first matchlock...learned ALOT while building it.

First off, I spent only about $50 for the whole project, $40 or so being the .45 caliber barrel from Numrich. Why .45? Because I was hesitant to spend real $$ on an authentic barrel not knowing whether the project would be a success or failure.

I found drawings in books (more about that later),and made a paper template of the shape I wanted. I used a Kentucky rifle stock shape for the drop (not too authentic), and I bandsawed the stock from a scrap 2x12 oak (yes, oak..remember, I was hesitant to spend $$). I took a small piece of same-size barrel scrap, sharpened the edges, shoved a rod in the end, and made a reamer/scraper for the barrel channel. When I was done, I use micro-bed to bed the barrel and hide the myriad of sins I created in the wood (oak is not easy to work with).

I hand cut and filed the pan, lid, site tube and flash guard from scraps of steel and welded them to the barrel. The rest of the metal for the lock, trigger guard, buttplate were also from the scrap bin. The thimmbles were from a T/C hawken.

The lock was where I had problems...I wanted a lock that fired with a sear lever. Remember how I mentioned I researched drawings? Well, I copied the lock exactly, but it would bind up and the dog wouldn't spring back after the lever was pressed. I took the lock to a local matchlock builder, George Silva, who has built countless snapping matchlocks (the kind with a button on the lockplate). When I explained my dilemna and showed him the lock and the drawings, he explained that illustrators often take artistic license, and that you are almost always better off to work from photos.

Anyway, after a few hours of trial and error, the lock was reconfigured and included a squeeze trigger instead of the sear bar.

The rifle is very accurate and fun, and look forward to my next project. Has anyone else had similar problems dealing with the "learning curve"?

First off, I spent only about $50 for the whole project, $40 or so being the .45 caliber barrel from Numrich. Why .45? Because I was hesitant to spend real $$ on an authentic barrel not knowing whether the project would be a success or failure.

I found drawings in books (more about that later),and made a paper template of the shape I wanted. I used a Kentucky rifle stock shape for the drop (not too authentic), and I bandsawed the stock from a scrap 2x12 oak (yes, oak..remember, I was hesitant to spend $$). I took a small piece of same-size barrel scrap, sharpened the edges, shoved a rod in the end, and made a reamer/scraper for the barrel channel. When I was done, I use micro-bed to bed the barrel and hide the myriad of sins I created in the wood (oak is not easy to work with).

I hand cut and filed the pan, lid, site tube and flash guard from scraps of steel and welded them to the barrel. The rest of the metal for the lock, trigger guard, buttplate were also from the scrap bin. The thimmbles were from a T/C hawken.

The lock was where I had problems...I wanted a lock that fired with a sear lever. Remember how I mentioned I researched drawings? Well, I copied the lock exactly, but it would bind up and the dog wouldn't spring back after the lever was pressed. I took the lock to a local matchlock builder, George Silva, who has built countless snapping matchlocks (the kind with a button on the lockplate). When I explained my dilemna and showed him the lock and the drawings, he explained that illustrators often take artistic license, and that you are almost always better off to work from photos.

Anyway, after a few hours of trial and error, the lock was reconfigured and included a squeeze trigger instead of the sear bar.

The rifle is very accurate and fun, and look forward to my next project. Has anyone else had similar problems dealing with the "learning curve"?