I have been back home from the class for a couple of weeks but I'm just getting around to posting. I just want to say outright that the class was WELL WORTH the time and money invested, it exceeded my expectations for sure. Jack Brooks was the instructor of the Trade Gun Class, he is a top notch instructor as well as a fantastic artisan. From what I could see of the other classes offered, all the other instructors were "Grade A" as well. The guys in my class were a terrific and talented bunch and it was a fun and rewarding experience working and learning with them!

My project was a Type "G" English trade gun, based on a surviving Wilson gun. The gun was started from a blank and all components besides the barrel and lock will be hand made. The barrel is a 46" Getz .62 cal smooth and the lock is R.E. Davis. I didn't have time to finish the gun in class, but the hard part is done. The barrel and lock is inlet, ramrod groove cut and hole drilled, thimbles made and the stock is rough shaped.

I have struggled with forming and shaping lock panels on both my previous guns. I guess all I can say is - Now I understand! It is amazing what some hands on training can do!

Here are a few pictures of my project in the works:

Working on barrel channel:

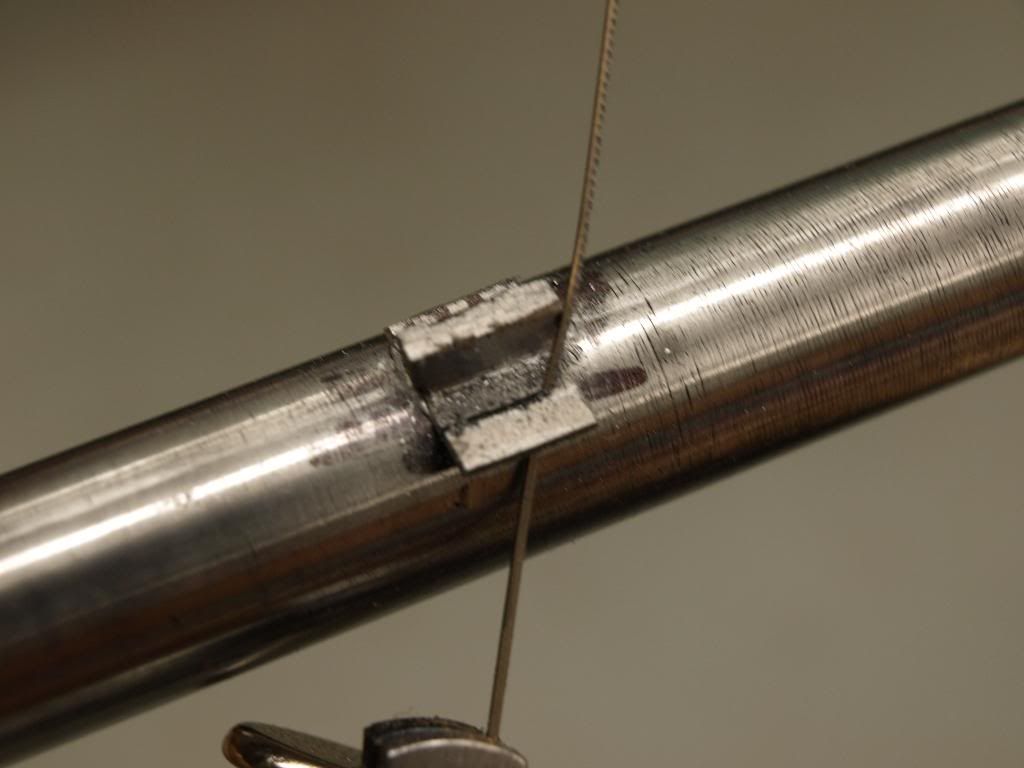

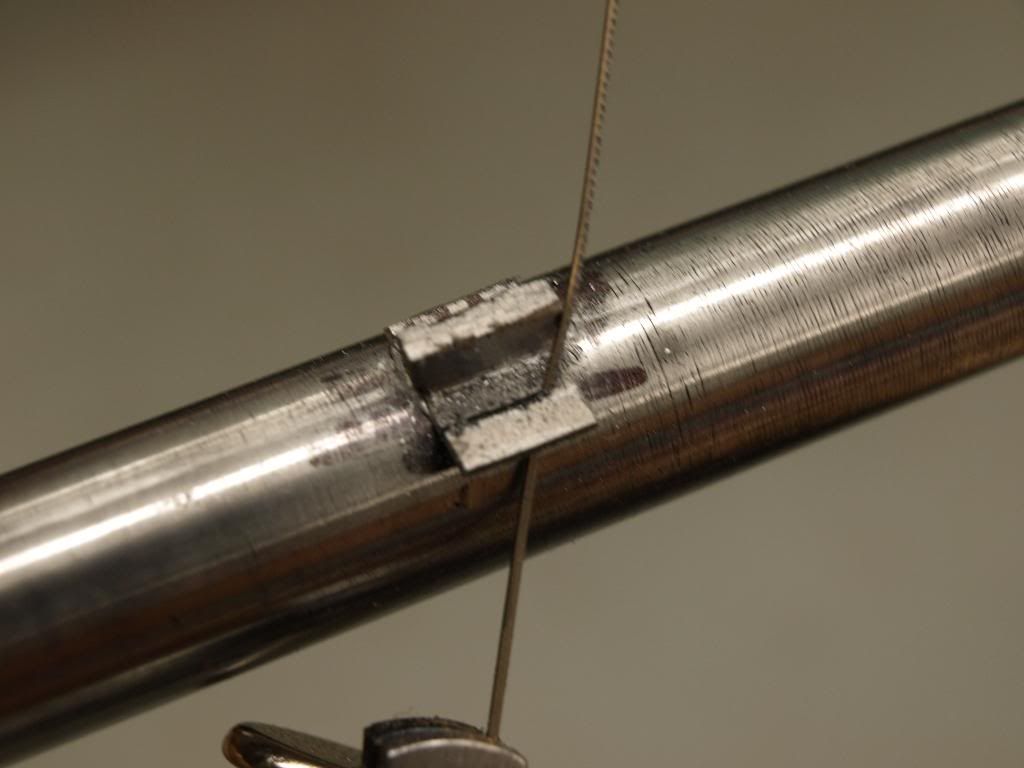

Barrel underlugs:

Formed Thimbles:

Cutting ramrod groove. Ever use the stock blank cutoff for a mallet?

Lock plate inlet:

Shaping stock:

Getting closer:

Class is over!

I will post more pics when I get the trade gun finished. Thanks for looking.

----------------

Curtis Allinson

My project was a Type "G" English trade gun, based on a surviving Wilson gun. The gun was started from a blank and all components besides the barrel and lock will be hand made. The barrel is a 46" Getz .62 cal smooth and the lock is R.E. Davis. I didn't have time to finish the gun in class, but the hard part is done. The barrel and lock is inlet, ramrod groove cut and hole drilled, thimbles made and the stock is rough shaped.

I have struggled with forming and shaping lock panels on both my previous guns. I guess all I can say is - Now I understand! It is amazing what some hands on training can do!

Here are a few pictures of my project in the works:

Working on barrel channel:

Barrel underlugs:

Formed Thimbles:

Cutting ramrod groove. Ever use the stock blank cutoff for a mallet?

Lock plate inlet:

Shaping stock:

Getting closer:

Class is over!

I will post more pics when I get the trade gun finished. Thanks for looking.

----------------

Curtis Allinson