I don;t know of any of the builder books that do not cover this in detail. If you don't have a builders book, I suggest you buy one as you will /do need it. My preference is "Gunsmiths of Grenville County" and after that wout be Chuck Dixons builder book.

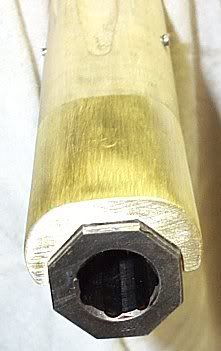

The nosecap us normally fitted to the stock in such a way it fits just as smoothly and detailed as the wood was, so there is no change other than color when you look at it, not a noticable dimensional change.

First you fit the nosecap to the end of the barrel at the designated place, then you trim the end of the stock down to where the nosecap will slip on the forstock wood from the end like a channel, slip it on, put the barrel in, make sure all fits correctly. I like to leave the Wood about 1/16 - 1/8" larger diameter than the nosecap where they meet for now, but want then to butt together flush. Get the nosecap to the wood so it is a perfectly straight flush fit, then most people glue the nosecap to the stock & let it dry. (Some use glue, some use epoxy, some use Acruglas, some use Microbed, some us no glue at alla decision you must make)

When this is all set & dry, you drill thru the nosecap at the bottom of it in the center (where the RR will cover it) it & rivet it or you insert a countersunk screw from the inside to the outside, tap the threads, put the screw thru & cut it off & file it off flush so it is flush with the surface of the nosecap. When I use a screw for this, I use a fine thread brass flatheasd screw about 6-40 threads or something very small. If you are going to rivet it you can use a small common nail or make a brass nail from a piece or brass rod, anneal it & forge a head on it, drill the hole & make a inlet for the nail head but it should be even with the barrel inlet (NOT below surface) and on the nosecap outside you slightly champer the hole you drilled. Insert the rivet in & leave about 1/8" sticking out & trim off the excess. It is VERY important the barrel inlet be sorrect to the barrel at this point, if not you may crack the stock at the nosecap doing this part. Now insert the barrel & lay it all over something steel & the barrel being flat with a piece of cloth between the two metal surfaces (must be flat as not to mar the barrel) now you carefully peen the rivit with a small hammer, taking care to it square at first to swell the shaft & then very carefully peen the edges just a lil. Don't go too much or you may cave in the nosecap in here. Now file it off flush & you have it.

I suggest you do a couple of sample practice runs on the Rivet way, as you can Easily screw the nosecap up here & ruin all of the work involved getting to this point. The screw way is usually the safer way for most.

It is imperative (looks wise) that this nosecap be fitted correctly & the allignment of such must stay parallel with the barrel flats. Again, the only thing you should notice as you get to the end of the barrel is a color change, not tipped up/down/uneven etc. just keep the lines straight & etc.

Good Luck.

This is a flared handmade nosecap installed on a bedded stock.

Sorry, I don't have photo of one that I riveted.