Thanks Paul.

Here is a couple of writeups I did I hope it helps. If you have any questions feel free to ask Ron

Since first writing this I have updated it a little. I first posted this quite a while ago but from time to time I am asked to give some info so I will post it again.

________________________________________________________________________

Part 1

Here is some very poor quality pictures and a description of how to wrap a bullet; sorry I am not a pro at writing.

Before I got to this point, I poured probably 200 bullets to get 75 perfect ones. I grade them for looks and weight. Any bullets with visible flaws are melted again and every good bullet that I keep is +or - .5 grains of the target weight sometimes I get even pickyer and go for +- .3 This gives me a constant product, AKA bullet, compare that to TC maxiballs or maxihunters. The lead I use is from a company called Rotometal. I get the pure lead, and it measures right at 5 to 6 BHN on my hardness tester. I used to use a bottom pour lee production pot for pouring lead. I quit using the bottom pour because the bullets didn’t come out like I wanted. I went to ladle pouring the bullets and the bullets come out a LOT better and the bullets are filled out better and the weight is more consistant.

Some guys wrap their bullets with wet paper. Most of them have undersized bullets, and are getting a bullet that fits perfectly after wrapping and are not sizing after they wrap the paper on the bullet. I would like to get a mould that would throw a bullet .446 and about 380 to 400 grains. RCBS has a mould like that but I have WAY too many moulds right now. I need to sell a couple I don’t use first.

Back to wrapping the bullets.

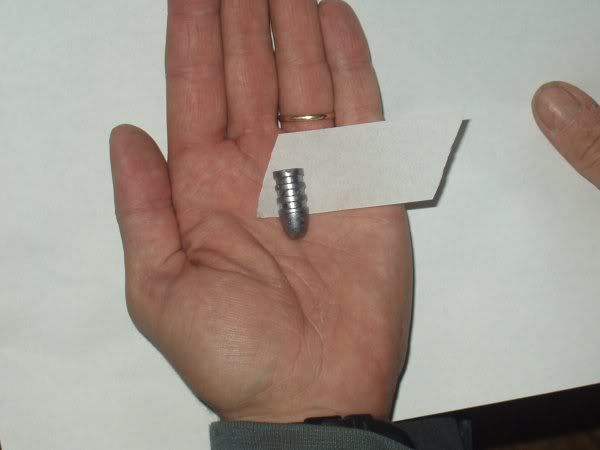

A lot of guys use a bullet wrapping board. I just use my fingers. In this first picture you can see the size and the shape of the paper, the paper adds about .008” to the diameter of the bullet before sizing.

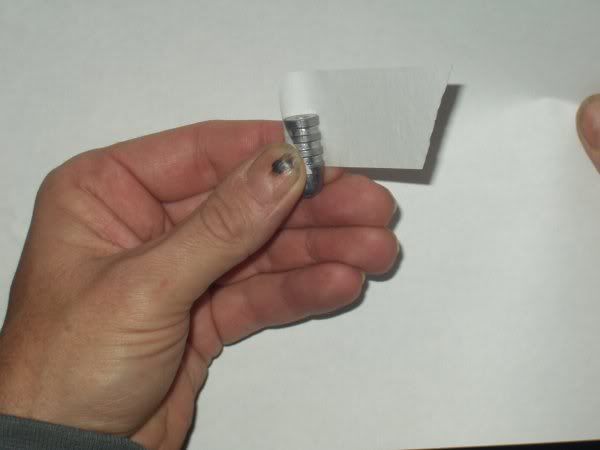

In these picture you can see the way I am starting the bullet into the wrap.

As I roll the bullet on I keep the paper tight as I can. When the paper rolls all the way on the two ends should meet and not overlap.

When I get the ends to meet I start to twist the tail.

With a hollow base bullet you can then push the tail into the base of the bullet. This picture is quite blurry sorry.

When I get to this point I run them through the sizer die and this is what the finished bullet looks like for the 45 cal 386 gr lee 459-405-HB and some others.

Part 2

On my 50 cal my gun likes bigger bullets than .504 but I size the Paper patched bullets to .501 this gives me a bullet that goes down with resistance but not real hard. After hunting with these bullets for a couple of years I know they will not come off the charge.

My 45 is .458, and it likes bullets that are .454 naked. I size these to .451 I could probably go to .452 for a finished size but the .451 load well and are very accurate. I don’t use any lube on the paper when I am sizing the paper patched bullet. The reason is the lube can and does cause the paper to rip off the bullet when seating the bullet. I size dry and add some lube when I am target shooting but leave them dry when I am hunting.

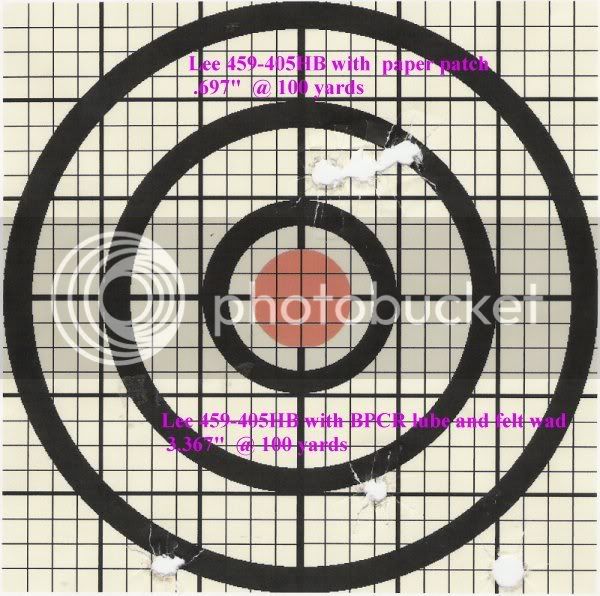

Here is a target that shows the benefit of the paper patch.

This is the rifle. It is a TC Renegade with a 32” long 1-18 twist Green mountain barrel. The sight is a Lyman 57 SML peep, and a Lee Shavers globe front sight with a level and long distance BPCR inserts. At 200 yards I can aim at a milk jug and put the front pin on the jug and see jug all the way around the front sight. It doesn’t cover up much of the target.

This is a couple of targets from one of my 50’s. The bullet was a 500 S&W bullet made with the Lee bullet mould.

This is the rifle, it is almost the same as the other one. I made this rifle for my son to someday shoot a moose with if he ever draws.

It is a double triggers TC Renegade with a 1-28 twist 50 cal Stainless steel Green Mountain barrel. The rear sight is the same as the other rifle. The front sight is a Lyman 17 AML. This is the rifle I shot the buck with later in the article.

I started to think a couple of years ago that Hornady would someday quit making the 410 gr 50 cal Great plains bullet, turns out I was right. That’s what started me to thinking about making my own bullets. I started out not doing the paper patch. I just got discouraged with my lead bullets because I was not getting the groups I wanted out of my rifles. I found an article about paper patching and wanted to try it. Since then I have played with paper type, bullet hardness, you name it I tried it. One thing I have found is paper patch bullets sometimes need a wad between the bullet and the powder, I make my own. I use a 3/8 pipe nipple and sharpen one end for the 45. For my 50 I use a 1/2 “ pipe nipple. I then cut out my wads out of wool felt I get from a fabric store. The 3/8 pipe will cut a wad that measures about, .505

The 1/2" pipe with cut a wad about .507 to .508. I like my wads to be oversized to make a sure seal and not let any gas get around the wad. I lube the wad with Hornady Great Plains lube. I also use the Hornady lube on the bullet before I load it.

One thing I have found is when you paper patch a bullet you get higher velocity from your normal charge. In the picture above you can see that the point of impact raised when I shot the paper patched bullets.

For me the paper patching has opened up my options in what I can shoot in my rifles. These days it seems like everyone is going to sabots. While I have had good luck with them we can’t use them to hunt here in Idaho. So I needed to find another way, and the factory conicals in my opinion are either great or crap. I love the Hornady Great Plains 410 gr 50 cal. Here is a TC bullet I found in one of my packs I bought.

With this kind of bullet out there I had to try to make my own. I hope I can help other guys that are looking for a different way to get good shooting bullets.

And last the final product of the paper patching. Here are a couple of bucks that a friend of mine and I killed with paper patched 460 gr 500 S&W bullets. My buck (the bigger one) was shot at a little over 100 yards. The bullet was a pass through and was not found. The buck of my friends was a quartering shot to him at 120 yards. The bullet hit the shoulder breaking the main bone in the shoulder. The bullet went on to travel through the buck and it exited out the flank on the opposite side. The buck dropped at the shot and the bullet exited and was never found.

His rifle is a TC whit Mountain carbine with a 1-38 twist. He has not done a lot of testing with his gun he just used my load. My load is 80 gr of Pyrodex P, a 460 gr paper patched bullet, and an over powder wad.

I tested this load a bunch in my rifle. I also have an Ohler 35 chronograph so I know what the rifle is REALLY doing .

velocity foot pounds of energy

muzzle 1310 1753

100 yards 1165 1387

150 yards 1108 1255

200 yards 1061 1151

250 yards 1022 1067

300 yards 988 997

I hope that this gives a little info on the paper patched hunting bullet. If you have questions feel free to ask. Ron