-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

patch cutter advice?

- Thread starter tree

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There are patch cutters that are sold via muzzelloading out lets that are a round chisel. You fold your fabric lay the punch on and smack it with a mallet...making them hand over fist :haha: .Patchs dont have to round. You can cut squares of cloth...about an inch and a half...and use them.

Lots of shooters cut right at the muzzle one at a time. I find that a pia myself, but fiddeling with dragging a precut patch out and loading is no faster, and maybe slower.

Lots of shooters cut right at the muzzle one at a time. I find that a pia myself, but fiddeling with dragging a precut patch out and loading is no faster, and maybe slower.

phoenix511

40 Cal.

- Joined

- Jul 28, 2008

- Messages

- 380

- Reaction score

- 1

Yes, the tool is a pair of scissors. My experience has shown no performance difference in round vs. square. Cut/rip the patch material in strips about 1 1/2" to 2" wide for your 20ga, soak the strips in the concoction of your choice, eyeball a cut to square size.

For my 20ga flint trade gun (no rear sight), I like Ballistol/water about 1 to 5, soak for a day, hang to dry, cut, store. Not too greasy, helps a bit in loading a slightly fouled barrel.

The patch separates from the ball near the muzzle, so it has almost no effect on the exterior ballistics

For my 20ga flint trade gun (no rear sight), I like Ballistol/water about 1 to 5, soak for a day, hang to dry, cut, store. Not too greasy, helps a bit in loading a slightly fouled barrel.

The patch separates from the ball near the muzzle, so it has almost no effect on the exterior ballistics

- Joined

- Jan 3, 2013

- Messages

- 20,091

- Reaction score

- 1,023

I made one ....easy to do if you have a lathe and a welder. I will post a picture tomorrow

eaglesnester

40 Cal.

- Joined

- Sep 25, 2009

- Messages

- 269

- Reaction score

- 1

Go to Brettuns Village. They are a leather tool supply house and sell arch punches. They will have the size punch U need to cut perfect round patches for your caliber. I ordered a 20 MM cutter to cut over powder wads for my 75 cal brown bess, fits my bore perfect. I use a patch knife to cut patches as I load like some did back in the day.

Pretty well answered by others.

Pick yer style and do yer thing. Let us know what you end up doing. Personally, I cut at muzzle.

Pick yer style and do yer thing. Let us know what you end up doing. Personally, I cut at muzzle.

Years ago, a long time muzzleloader hunter gave me a couple of ball bearings, 1 1/2" and 2" in diameter. With a pipe thimble and a piece of seamless tubing, IDs of 1" and 1 1/2", placing the patch material between the tubing and the ball, a rap from a 5# hammer produces a 1" and 1 1/2" patch. I can do up to 6-8 thicknesses at a time.

Square patches work fine. Rather then scissors, I use a rotary cutter, from a fabric store, & a straight edge. You will have to get the special cutting board to use with the cutter. The patch material can be folded to cut multiple layers at once. If the straight edge is the same width as the desired patch size, no measuring is required. After the cloth is cut in strips, use the same method to cut strips in to squares.

Paul

Paul

Moose in canoe said:Square patches work fine. Rather then scissors, I use a rotary cutter, from a fabric store, & a straight edge.

Amen...here are some cotton duck after firing some sold brass balls...I normally use square pillow ticking patches cut from JoAnne Fabrics but needed some thicker material for the brass ball tests.

- Joined

- Jan 3, 2013

- Messages

- 20,091

- Reaction score

- 1,023

Patchs dont have to round. You can cut squares of cloth

True and square are easier to make...but I keep going back to round patches, I find it easier to center the ball in the patch over the muzzle with a round patch than a square one. Maybe it's just me. :idunno:

Where did you get the brass balls? :grin:

And, other than the fact that you can use them more than once, what are the advantages?

Curious, as I do have a .58 cal 1803 Harper's Ferry.

And, other than the fact that you can use them more than once, what are the advantages?

Curious, as I do have a .58 cal 1803 Harper's Ferry.

I wil use a lot of precut round. So I understand. You can make a loading block and push a prb into that and cut it off. Push them out the bottom. Put your patch in your holder and repeat.

Black Hand

Cannon

- Joined

- Mar 17, 2005

- Messages

- 9,348

- Reaction score

- 896

Scissors - square patches work just fine.tree said:I would like to precut my own patches for loading round ball in

my 20ga Flint smoothbore. Is there a good tool for doing this?

Was researching / testing for non-lead alternatives when there seemed to be a lot of national attention on lead bans, eliminating lead projectiles, etc.Grumpa said:Where did you get the brass balls? :grin:

And, other than the fact that you can use them more than once, what are the advantages?

Curious, as I do have a .58 cal 1803 Harper's Ferry.

Bought a couple packs of these from "Online Metals" as they happened to be .5625" diameter, perfect size to test in my .58cal Early Virginia.

Deadly accurate, then hunted them that fall, took deer with them, etc.

Incidently, all that also proves the point that PRB accuracy has no dependency on a PRB "obturating" into the grooves, as the post-firing dimensions of this rock hard solid brass ball had not changed what-so-ever. Reused 1x fired range test balls for deer hunting same as if they were new virgin balls.

- Joined

- Jan 3, 2013

- Messages

- 20,091

- Reaction score

- 1,023

Here is a patch cutter I made years ago. You put it in a drill press and run it up and down while it spins, cutting out patches from cloth placed on a cutting board.....about I every 5 seconds.

- Joined

- Dec 25, 2011

- Messages

- 9,347

- Reaction score

- 4,523

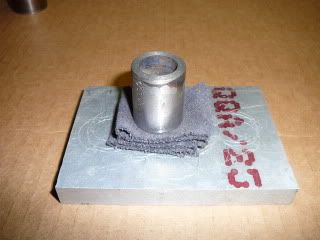

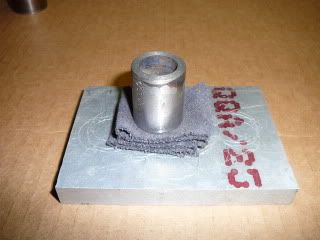

Make up a set of these and use them in a good vice. It is just as efficient of patch cloth as is cutting them at the muzzle if careful when folding the strips in zig-zag pattern.

I make all my pre-cut patches with these simple tools made in the shop from scrap metal.

The punches are very easy to keep sharp as well.

Punch through the cloth in the vice and twist the patch wad to shear off any strands that did not get cut.

It'll make a dozen or so in one punch.

I make all my pre-cut patches with these simple tools made in the shop from scrap metal.

The punches are very easy to keep sharp as well.

Punch through the cloth in the vice and twist the patch wad to shear off any strands that did not get cut.

It'll make a dozen or so in one punch.

- Joined

- Jan 3, 2013

- Messages

- 20,091

- Reaction score

- 1,023

I make all my pre-cut patches with these simple tools made in the shop from scrap metal.

I also made mine from scrap...Quick ad dirty to prove the concept....it worked well enough that I never got around to making a proper one. :grin:

The ideal patch size for loading a roundball in a 20 guage (.62) is 1.6 (about 1 5/8) inches square or diameter.

Anything from 1 1/2 to 1 3/4 will work equally well.

Anything from 1 1/2 to 1 3/4 will work equally well.

I took an old 1-1/2"hole saw. Ground down the teeth to a sharp edge, and put it in my drill press to cut several layers of patch material at one time. I usually get 10 to 15 patches per each run of the press. Can go thru a yard of patch material in short order.

- Joined

- Dec 25, 2011

- Messages

- 9,347

- Reaction score

- 4,523

I prefer the punching process rather than the rotary cutting action as the cloth weave is not torque stressed with this method which I believe inclines/encourages the weave to twist , wrinkle or open up, especially when multiple layers are being cut.

Similar threads

- Replies

- 97

- Views

- 6K