I mentioned in another thread that I'm a historic blacksmith. I am very fortunate to be and continue to be trained in the techniques and philosophy of the early blacksmiths. I believe this has given me a perspective that has really helped me a lot in a variety of ways.

An example is a simple patch knife that I make. There were, and still are, a lot of styles of patch knives. Mine is a one piece, entirely forged, knife that draws it's inspiration from the early blacksmith knives, sometimes called a "rat tail".

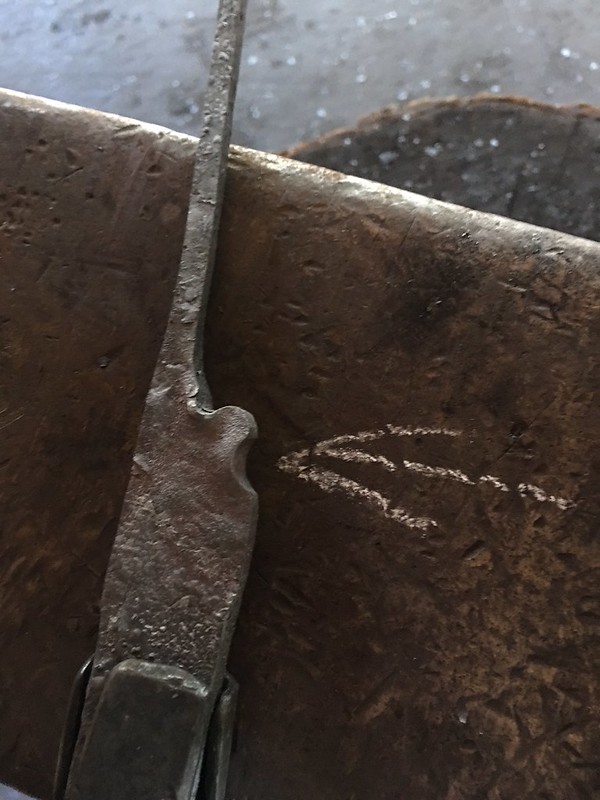

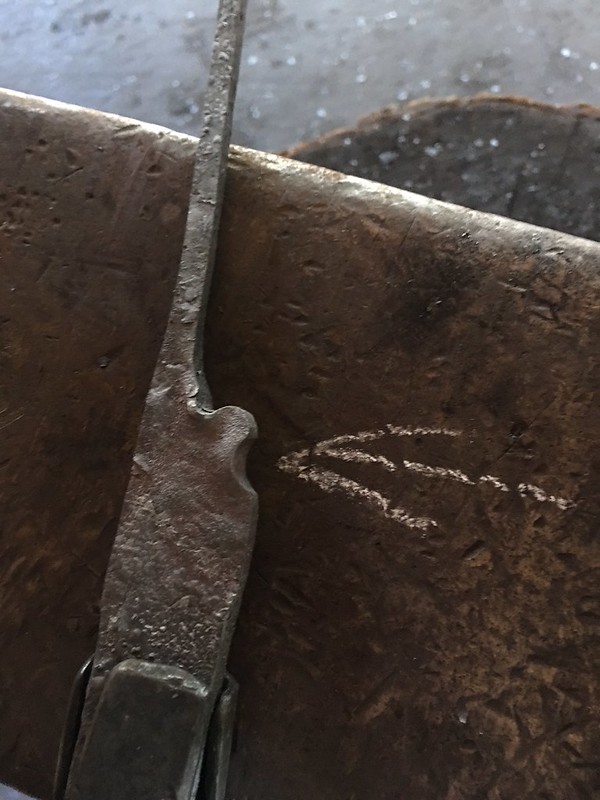

Here are some progress shots of it's development through the forging process.

The first step is to start the "tail". On the edge of the anvil. Then keep drawing it out.

Then I have to isolate some material for the rivet. The rivet is something I came up with.

I forge the blade, straighten and file the rivet to shape. Then I punch a hole in the finger guard.

Now I bring the handle around to shape and attach it. I peen the rivet.

After some fine tuning of the shape.

Grind the bevels and heat treat.

I usually make the blade about 3 inches. This is 1084 high carbon steel.

An example is a simple patch knife that I make. There were, and still are, a lot of styles of patch knives. Mine is a one piece, entirely forged, knife that draws it's inspiration from the early blacksmith knives, sometimes called a "rat tail".

Here are some progress shots of it's development through the forging process.

The first step is to start the "tail". On the edge of the anvil. Then keep drawing it out.

Then I have to isolate some material for the rivet. The rivet is something I came up with.

I forge the blade, straighten and file the rivet to shape. Then I punch a hole in the finger guard.

Now I bring the handle around to shape and attach it. I peen the rivet.

After some fine tuning of the shape.

Grind the bevels and heat treat.

I usually make the blade about 3 inches. This is 1084 high carbon steel.