With a tight patch, there is a tight spot 5 inches down and then the patch runs smooth the rest of the way down. seems tighter from the tight spot to the muzzle. Would this barrel still be serviceable to ream out if there were a bulge or would it be weak?

Stop please

A bulge will feel like the bore resists, THEN you get a very short spot where it suddenly feels loose, then it should tighten back up.

IF it's tight for about 5" then gets loose for the rest of the length, which is about 34" on a frontier..., and the patch isn't coming free of the ball when the ball hits the smoother spot, then that's

not a bulge.

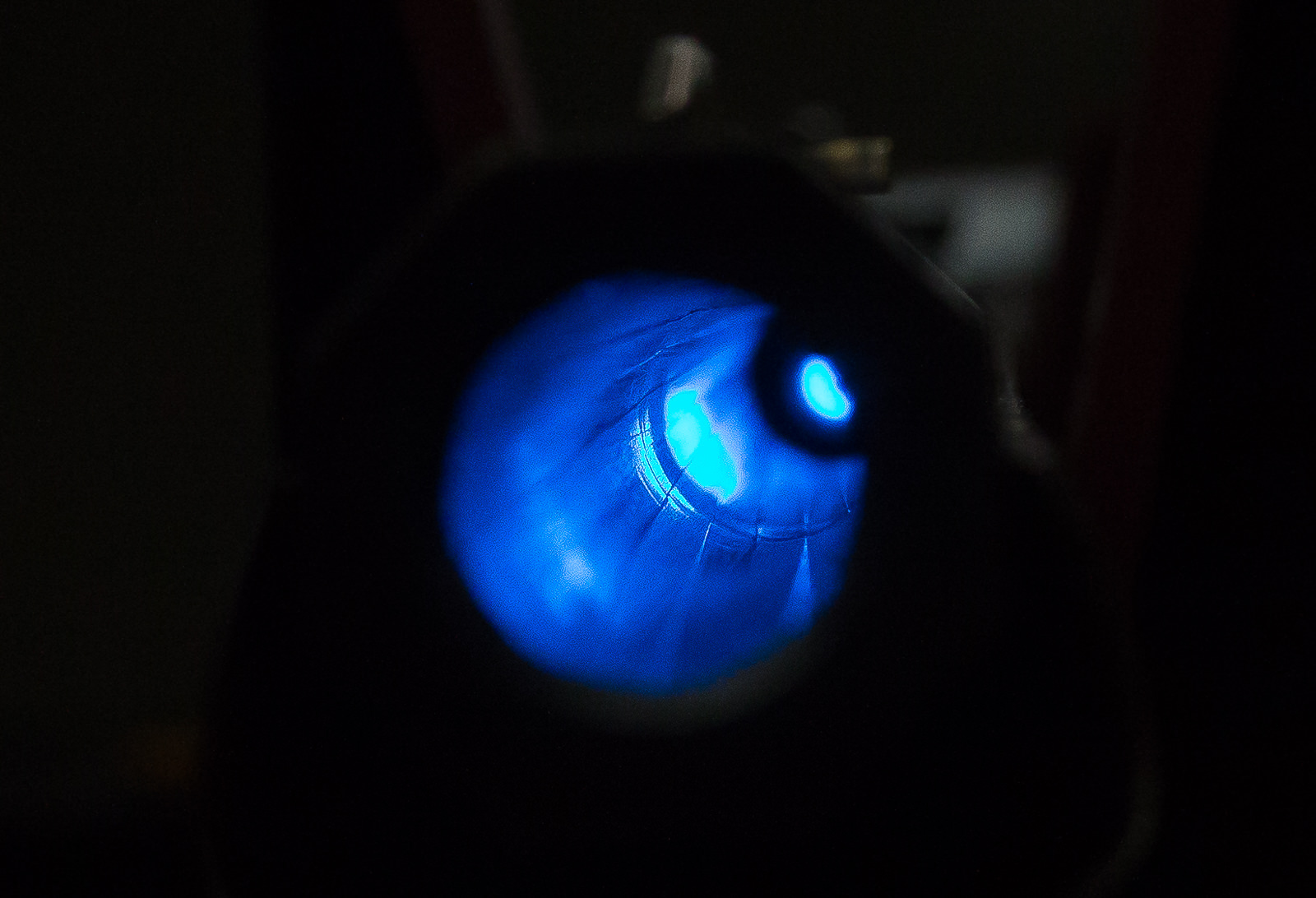

Have you taken a look at the bore? You can take something like a AAA battery, and drop it with the flat side toward the muzzle, then use a flashlight to reflect off the butt of the battery, and illuminate the interior of the barrel.

The good news is that you may have a rough spot (from any number of reasons) in the last 5" of the barrel. That can be polished out if that's all there is.

The bad news is that it may be an improperly machined barrel. If there are no rough spots and there is no bulge, they may have cut the barrel wrong, and when it became rifled, the lands are too shallow. IF that's the case, and the bore just tightens at the muzzle, it should still shoot conical projectiles pretty well. In the book,

The Muzzle-Loading Caplock Rifle, Ned Roberts documents folks intentionally opening up most of the bore of their rifle, tightening near the muzzle, to shoot conical projectiles.

However, If it's simply improperly machined, well the other option is as folks suggested...., have it reamed out smooth to a .62 (or maybe a .58/24 gauge if that's too big). You might find it more versatile and more fun that way. :wink:

LD