duelist1954

40 Cal.

- Joined

- Jun 27, 2011

- Messages

- 430

- Reaction score

- 73

I had to put my flintlock rifle build on hold recently when Combat Handguns magazine asked me to write an article about building a flintlock pistol from a kit.

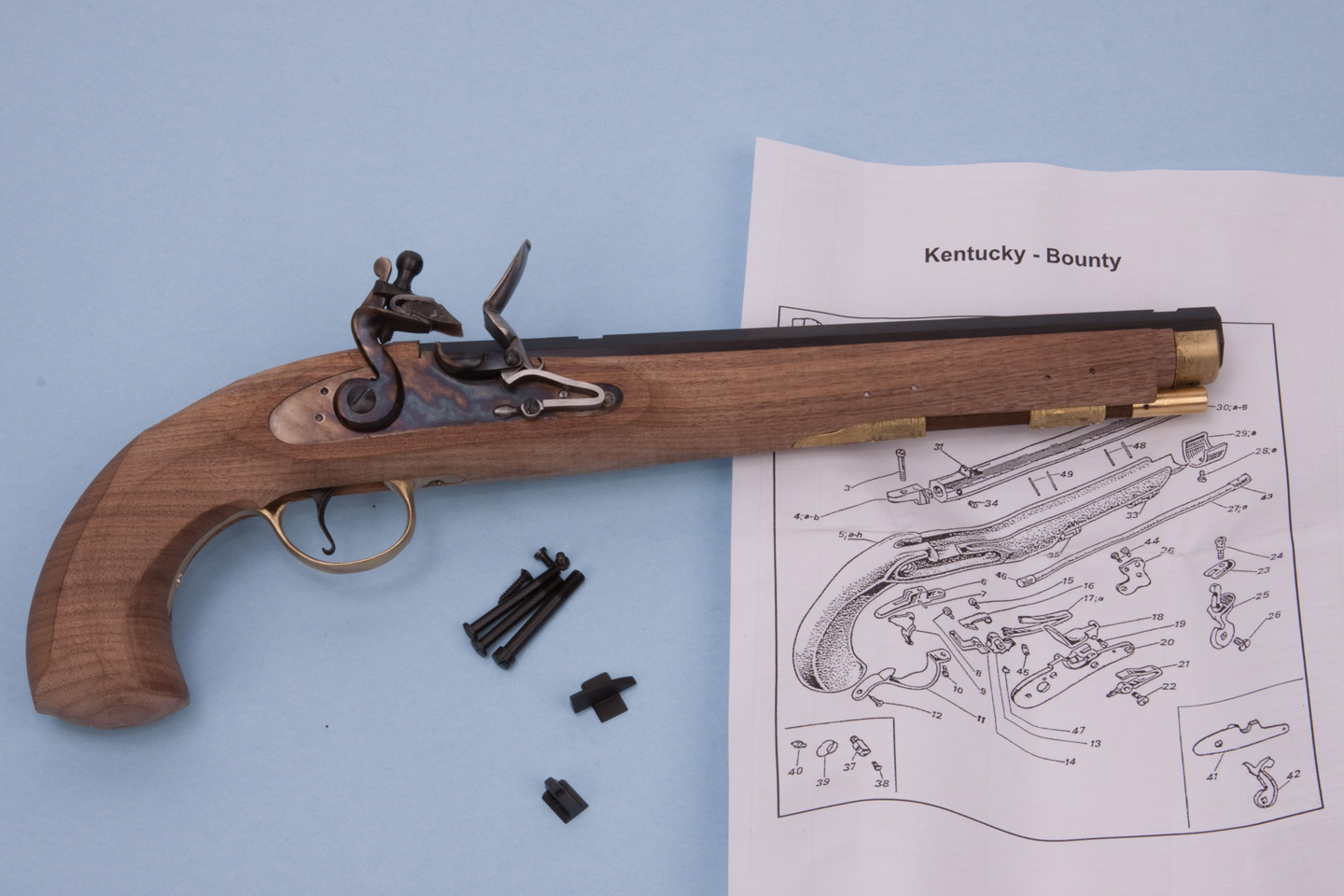

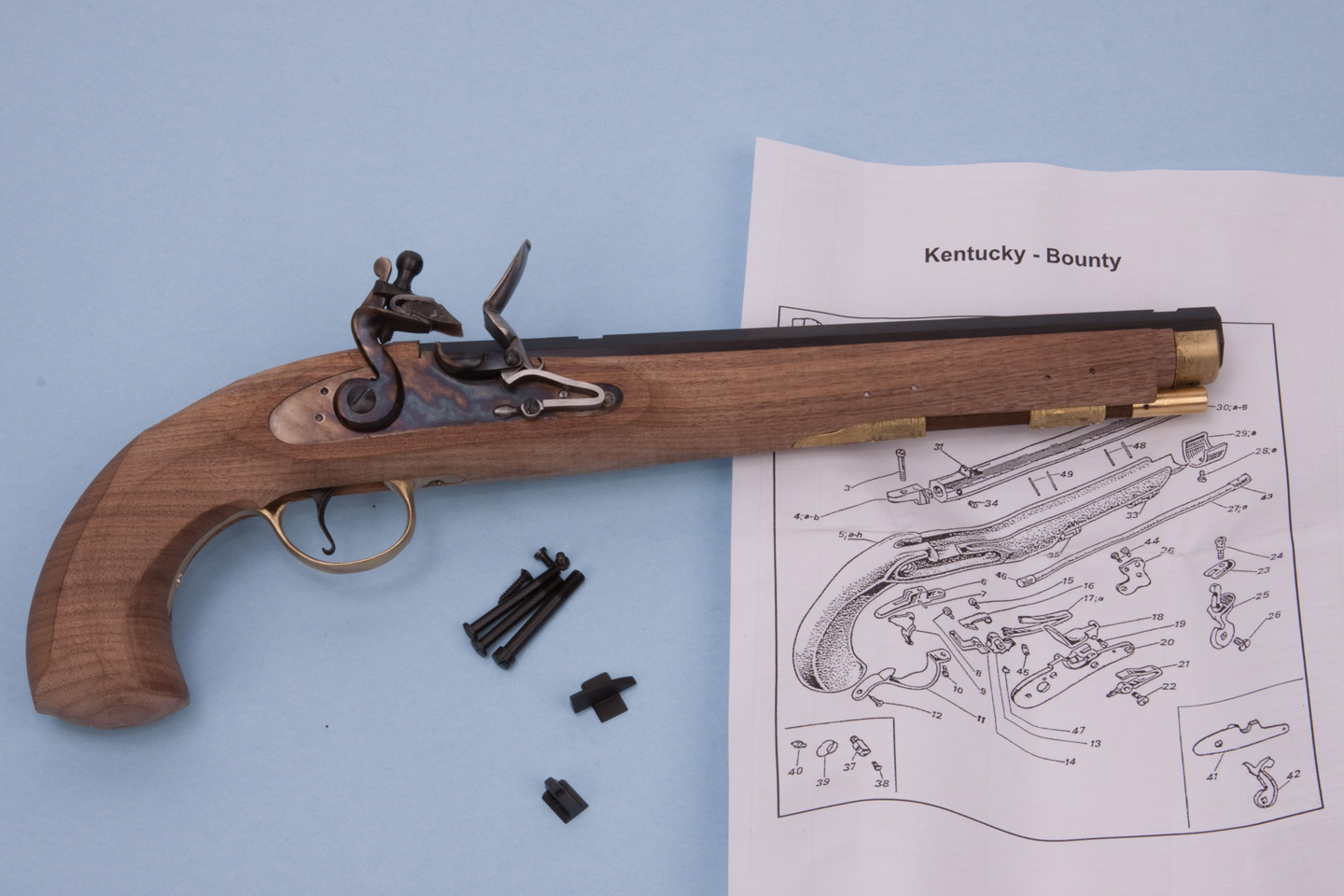

I selected this Pedersoli .45 caliber Kentucky pistol kit from Dixie Gun Works. This is a very easy kit that anyone should be able to build.

I'll do a short video series on assembling the kit. In this first installment I'll show you what comes with the kit, and I'll show you how to shape the nose cap and clean up the brass ramrod thimbles...more updates to come.

https://www.youtube.com/watch?v=nHr0951AXYM

I selected this Pedersoli .45 caliber Kentucky pistol kit from Dixie Gun Works. This is a very easy kit that anyone should be able to build.

I'll do a short video series on assembling the kit. In this first installment I'll show you what comes with the kit, and I'll show you how to shape the nose cap and clean up the brass ramrod thimbles...more updates to come.

https://www.youtube.com/watch?v=nHr0951AXYM

Last edited by a moderator: