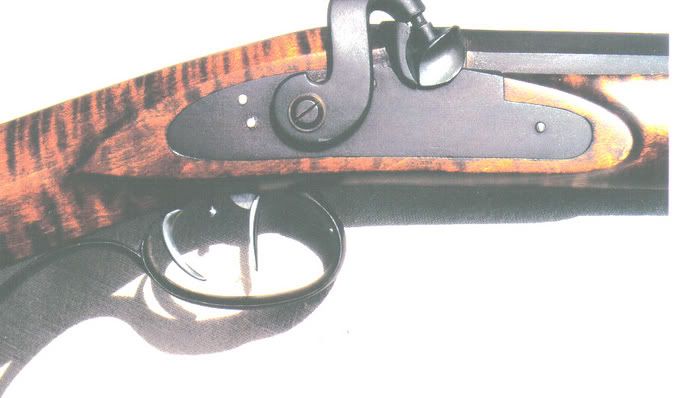

I rough sanded out the Hawkens rifle that I have been working off and on for the past 6 months. I built it with a closeout Rice barrel in 54 cal. and a stock second from TOW. Finally got the forend shaped down to where I wanted. Before I start the finish sanding, is there any place where more wood needs to be removed? I just finished rounding off the sides of the barrel channel walls so that they taper down to the barrel. Also, any suggestions as to stains? I'm thinking of using aqua fortis. I'm still debating whether or not to put a capbox in the butt. There isn't much figure where one would go.

btw, it shoots really nice. Not much kick at all. I need to file down the front sight a bunch though. Windage was only off by about 2" at 50 yards.

btw, it shoots really nice. Not much kick at all. I need to file down the front sight a bunch though. Windage was only off by about 2" at 50 yards.