Skogarmann

32 Cal.

- Joined

- Jan 27, 2014

- Messages

- 8

- Reaction score

- 0

Hello, I recently bought a new Pietta 1860 (my first cap and ball revolver). I took it out today and shot it to see how it went. I noticed two main issues with it:

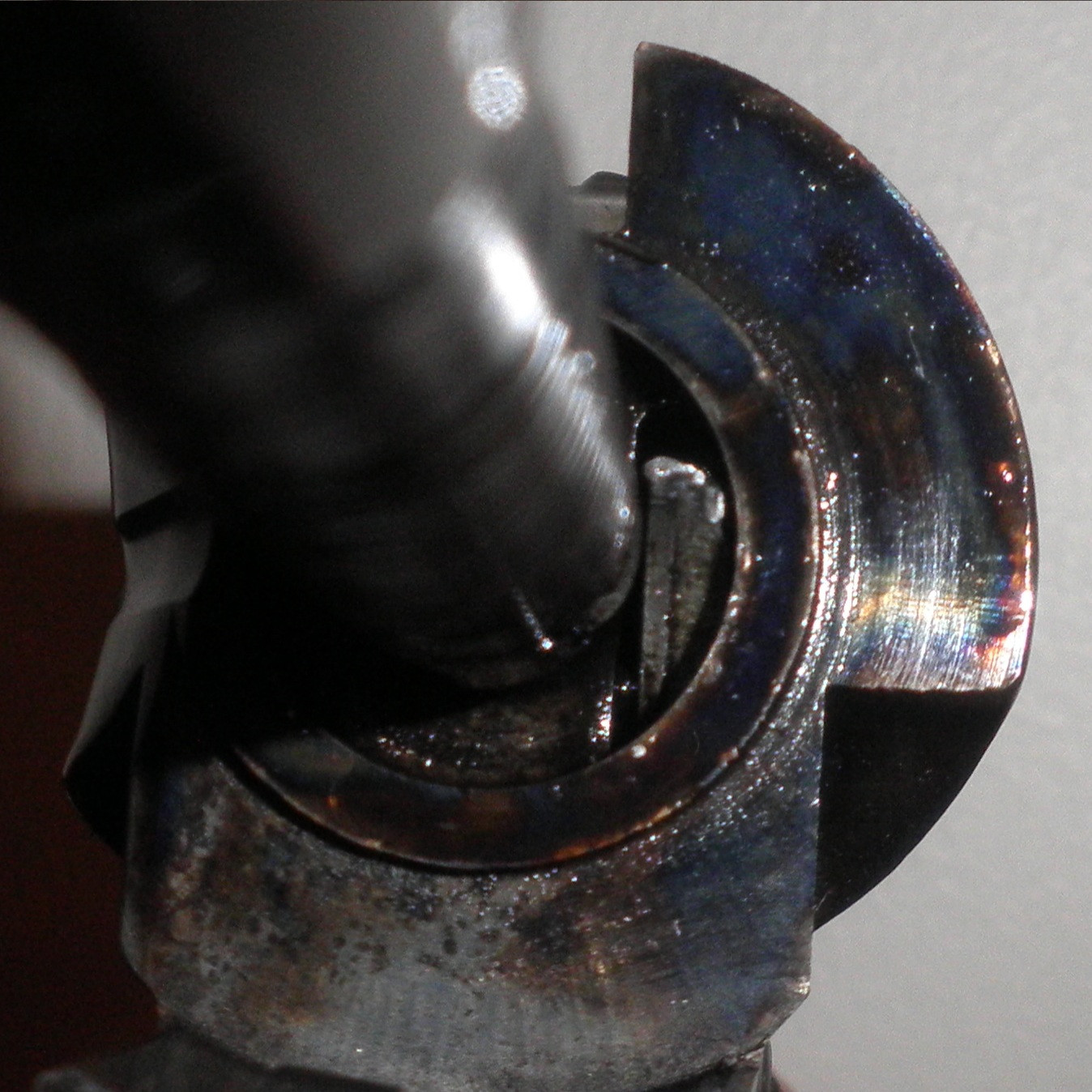

1) It was smashing caps pretty badly. I've heard others having problems with caps falling off and getting into the workings, but these were generally smashed hard in place on the nipples. It usually wasn't an issue and they'd often fall off and away when I cocked the hammer. But some of them were so badly smashed up and stuck on, that their jagged, protruding edges would prevent the cylinder from turning.

Is this normal and can I fix it so that it doesn't happen? I'm using Remington No.10 caps. I'm glad that I'm not having other issues, like caps falling off; but if I could fix this issue it would be very nice.

2) The cylinder or some mechanism seems to get gummed up or something like that. After just 4 shots trough it (using Triple 7 powder because it was all that Cabelas had in stock when I bought the revolver), the cylinder would not properly turn. To finish the final 2 shots, I had to pull the hammer back as much as I could and jiggle the cylinder so that it turned. This didn't required much force and when the cylinder turned, the hammer would cock fully back and be ready to fire.

For some reason the mechanism that turns the cylinder seemed unable to turn it. I tried pulling the hammer back hard and sometimes it worked, but other times nothing happened. I'm not sure what exactly causes this and how I can fix it.

I kept firing, a total of 18 shots (didn't have much time and those 18 took me an hour and a half somehow!) and kept having these same problems. Before reloading the cylinder, I took the barrel and cylinder off and wiped the base pin and face, as well as the...um...clicky thing (I think it's the bolt according to Taylors Firearms?) on the bottom of the frame (on the top face, below the base pin).

This seemed to allow the cylinder to turn properly when I pulled the hammer back, but it still felt kind of grainy and reluctant. After the first shot or 2, it would go back to needing me to turn the cylinder with one hand while pulling the hammer back with the other.

Is this normal? How can I fix it or prevent it from happening so much? I've had a friend tell me "it's just how they are", but I'm sure that these revolvers must be able to run much more smoothly and it's just operators error.

Also, what should I put on the base pin after cleaning it? Right now I've just put some generic gun oil on it, but it seems like it needs some kind of grease. Is there anything in particular I should use or is gun oil fine?

Any answers or general tips/advice would be very much appreciated. Thanks!

1) It was smashing caps pretty badly. I've heard others having problems with caps falling off and getting into the workings, but these were generally smashed hard in place on the nipples. It usually wasn't an issue and they'd often fall off and away when I cocked the hammer. But some of them were so badly smashed up and stuck on, that their jagged, protruding edges would prevent the cylinder from turning.

Is this normal and can I fix it so that it doesn't happen? I'm using Remington No.10 caps. I'm glad that I'm not having other issues, like caps falling off; but if I could fix this issue it would be very nice.

2) The cylinder or some mechanism seems to get gummed up or something like that. After just 4 shots trough it (using Triple 7 powder because it was all that Cabelas had in stock when I bought the revolver), the cylinder would not properly turn. To finish the final 2 shots, I had to pull the hammer back as much as I could and jiggle the cylinder so that it turned. This didn't required much force and when the cylinder turned, the hammer would cock fully back and be ready to fire.

For some reason the mechanism that turns the cylinder seemed unable to turn it. I tried pulling the hammer back hard and sometimes it worked, but other times nothing happened. I'm not sure what exactly causes this and how I can fix it.

I kept firing, a total of 18 shots (didn't have much time and those 18 took me an hour and a half somehow!) and kept having these same problems. Before reloading the cylinder, I took the barrel and cylinder off and wiped the base pin and face, as well as the...um...clicky thing (I think it's the bolt according to Taylors Firearms?) on the bottom of the frame (on the top face, below the base pin).

This seemed to allow the cylinder to turn properly when I pulled the hammer back, but it still felt kind of grainy and reluctant. After the first shot or 2, it would go back to needing me to turn the cylinder with one hand while pulling the hammer back with the other.

Is this normal? How can I fix it or prevent it from happening so much? I've had a friend tell me "it's just how they are", but I'm sure that these revolvers must be able to run much more smoothly and it's just operators error.

Also, what should I put on the base pin after cleaning it? Right now I've just put some generic gun oil on it, but it seems like it needs some kind of grease. Is there anything in particular I should use or is gun oil fine?

Any answers or general tips/advice would be very much appreciated. Thanks!