Duane said:

I had the bridging problem on two patent breech guns. In both cases the powder was not filling up the chamber. When I stuck a pick in the hole after running the ball home there was little or no resistance from the powder. I always smack the breech area after pouring the powder but it didn't help. My Pedersoli Mortimer needed an enlarged chamber and a rather expensive custom full stock Hawken finally got a new breech. Both guns are for hunting. I don't clean between shots because I wouldn't be able to do that if a follow up shot was necessary in the field.

Duane

Many of the parts on factory mades leave a lot to be desired. They likely left the powder cavity as cast and perhaps too small or ?

Many of the parts sold by suppliers are just kits and need rework to be as good as they should be. But a many do not understand this.

I have used a TOW Flint breech on a pistol years ago an can't recall if I modified it of not. I never gave any problems for the several years I used it. And I hunted with it. But what the CURRENT production is like I could not say.

I have a shop made Nock breech in my 16 bore and it has a vent between the antechamber and the barrel that is about .190" IIRC.

it works flawlessly. With good powder, wiped or not. My "service load" for this rifle is 140 gr of FF Swiss. It and the standing breech have been case hardened in colors.

Its also a recessed breech type (Manton's patent from about 1810).

I have a Swivel Breech rifle with patent breeches in the barrels. These have a 3/8" powder chambers cut with a ball end mill so they are cupped at the breech end. It works well with FF or FFF and I have killed a couple of deer with it and missed at least one Antelope.

These have given good service in hunting and shooting with and without hunting. But there are no sharp edges and they are somewhat polished in the interiors.

A friend has a percussion rifle I built that I was SURE would work in any circumstance, but when wiped it needed to have a cap popped to make it shoot reliably. So?

I need to debreech this and look at it. But the breech is case hardened now so it will require carbide to reshape the interior if it needs it and if the current owner wants it done.

So, flint patent breeches DO work if done PROPERLY. But the Nock is sensitive to powder quality and powder that produces large flakes of fouling WILL clog it in 2-3 shots and cause it to fail to fill the anti-chamber and then flash in the pan.

But it will not do this with a powder like Swiss.

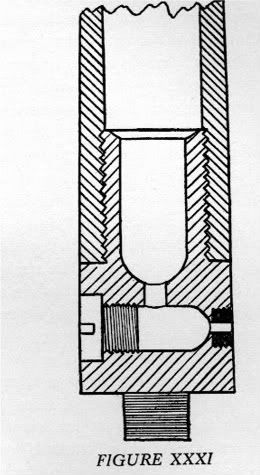

This is the Nock breech as drawn in George's "English Guns and Rifles"

This was the original and actually only "patent" breech or so some English shooters on another site have said.

I never use a touch hole pick as such and don't carry one in my pouch. If the vent and the rifle is properly done its very seldom needed, if so I use something in the field whittled stick or a dry grass stem.

People also like to shoot cheap powder. The original Nock (patented in 1782 or 89) does not like powder that fouls excessively. The chambered breech plug, which was much like the swivel breech breeches but drawn in Geroge's book with a smaller passage probably did not either.

Dan