Wish I had saved it but I read somewhere that experiments with artillery long ago when black powder was the only used that the limits of max range vs pressure were proportional between diameters...This was a detailed explanation that yes you can get bigger bang with more powder but the fall of pressure was that once you get to a certain point thus range did not change enough to use any larger charge than what produced the best range. That black powder had its limits.

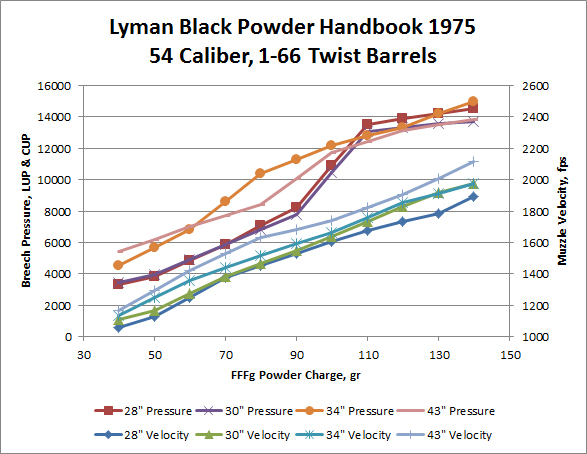

Yes, for BP cannons, there is an optimum powder charge that gives maximum velocity and range. Go to Prop IV near the bottom of this

webpage for the calculations. It says, "So the length of charge for maximum muzzle velocity is 1/2.72 of the length of the barrel." In the case of the 28" barrel, the optimum powder charge would be 28/2.72 = 10.3 inches long. We would never load a 10" column of powder in a muzzleloader rifle, so in a practical sense there is no optimum powder charge for a maximum velocity in a muzzleloader rifle.

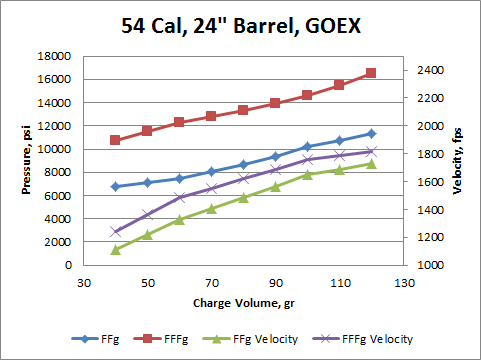

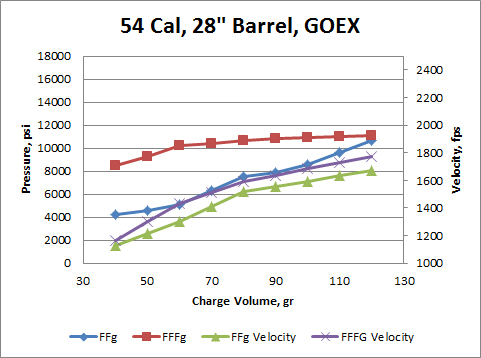

No, I suspect there is a problem with the GOEX 3Fg data with the 28" barrel. It shouldn't bend over like that.

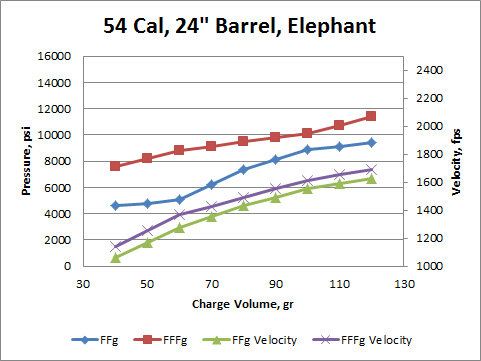

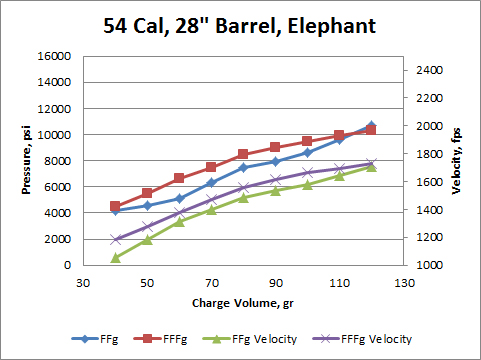

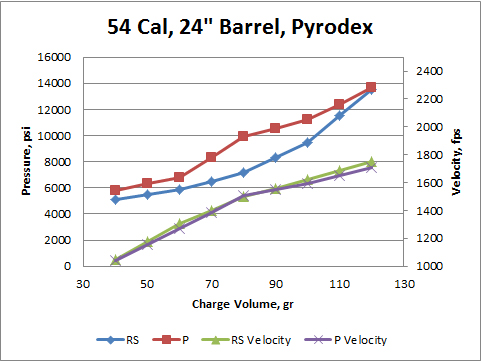

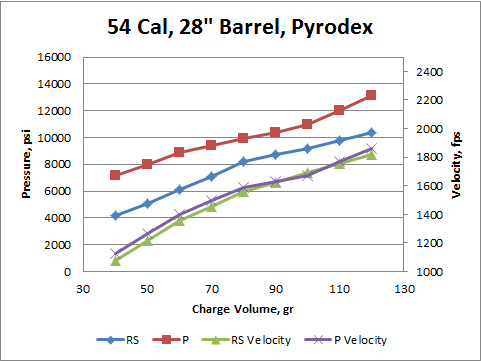

I generated graphs for the Elephant powder data and the Pyrodex powder data. None of the pressure curves bend over like the questionable data for the 3Fg in the 28" barrel.

First the Elephant powder in the 24" barrel. The pressure curves are similar to the GOEX data in this barrel, but they are lower. There are also a couple of kinks in the 2Fg curve. The velocity curves are shaped as expected and lower than the GOEX velocities in this barrel. This matches with what I have heard about the Elephant powder. It's not as powerful or efficient as GOEX. It is also interesting that the difference between the 2Fg and 3Fg velocities are not as great as for the GOEX powders.

The Elephant powder in the 28" barrel. The pressure curves almost intersect at the lowest charge volume and do intersect between 110 and 120 grs. Not the expected behavior, but it is worth pointing out that the Elephant 3Fg powder in the 28" barrel does not bend over like the GOEX 3Fg data.

On to the Pyrodex data, this is for the 24" barrel. I chose to compare the Rifle/Shotgun granulation to the Pistol granulation thinking it would be a relative comparison for the 2Fg to the 3Fg black powder. Pyrodex doesn't appear to burn the same as real black powder as the velocity curves almost overlap each other.

The Pyrodex data in the 28" barrel. Again, the velocity data for the two granulations are almost the same. The pressure curves look more like some of the GOEX and Elephant curves in the 24" barrel.

I'm not going to show the graphs, but the velocity curves for Pyrodex RS and Select also overlay each other. In these two barrels, it doesn't appear to matter which granulation of Pyrodex one chooses to shoot. The velocities are pretty much the same for all three.

Looking at all these graphs, it appears that measuring consistent pressure data, even under laboratory conditions, is difficult to do.

Lyman had this to say about their procedures in testing:

Lyman 2nd Edition Black Powder Handbood said:

The data listed in this section has been tested by Lyman technicians under controlled laboratory conditions...

The velocity and pressure data shown was produced using five shot test strings. The test barrels were cleaned between each five shot string. We felt that this would best duplicate "real world" shooting conditions. All pressure data collected was with the use of piezo electronic equipment and is measured in actual pounds per square inch (PSI). Standard black powder barrels were modified to accept a pressure transducer and were connected to a peak pressure meter.

I'm not sure what to make of this pressure data. Theoretically, one shouldn't see a difference in peak pressure with different barrel lengths, but in this data we do. The internal dimensions of the two barrels may be different and/or the finish or roughness of the barrels may be different. Too bad they didn't conduct the test by shortening the same barrel. But even with these differences, I would expect more consistency between the shapes of the curves in the same barrel with the different powders.

If the pressures are real, meaning the piezoelectric equipment was working right and measuring actual pressures accurately under controlled conditions and still getting this much variation, it makes me wonder what type of pressures we are getting in the field?